The standard terminals are 18, 19, 27, 29, 32, and 33. VLT

®

General Purpose I/O MCB 101 terminals are X30/2, X30/3,

and X30/4. Terminal 29 functions as an output.

Functions dedicated to only 1 digital input are stated in

the associated parameter.

All digital inputs can be programmed to these functions:

[0] No

operation

No reaction to signals transmitted to the

terminal.

[1] Reset Resets frequency converter after a trip/alarm.

Not all alarms can be reset.

[2] Coast

inverse

(Default digital input 27): Coast stop, inverted

input (NC). The frequency converter leaves the

motor in free mode. Logic 0⇒coast stop.

[3] Coast and

reset

inverse

Reset and coast stop inverted input (NC).

Leaves motor in free mode and resets

frequency converter. Logic 0⇒coast stop and

reset.

[4] Quick stop

inverse

Inverted input (NC). Generates a stop in

accordance with quick stop ramp time set in

parameter 3-81 Quick Stop Ramp Time. When

the motor stops, the shaft is in free mode.

Logic 0⇒quick stop.

[5] DC brake

inverse

Inverted input for DC brake (NC). Stops motor

by energizing it with a DC current for a certain

time period. See parameter 2-01 DC Brake

Current to parameter 2-03 DC Brake Cut In Speed

[RPM]. The function is only active when the

value in parameter 2-02 DC Braking Time is

dierent from 0. Logic 0⇒DC brake.

[6] Stop

inverse

Stop inverted function. Generates a stop

function when the selected terminal goes from

logical level 1 to logical level 0.

The stop is performed according to the

selected ramp time:

•

Parameter 3-42 Ramp 1 Ramp Down

Time,

•

Parameter 3-52 Ramp 2 Ramp Down

Time,

•

Parameter 3-62 Ramp 3 Ramp down

Time, and

•

Parameter 3-72 Ramp 4 Ramp Down

Time.

NOTICE

When the frequency converter is at the

torque limit and has received a stop

command, it may not stop by itself. To

ensure that the frequency converter

stops, congure a digital output to [27]

Torque limit and stop. Connect this

digital output to a digital input that is

congured as coast.

[8] Start (Default digital input 18): Select start for a

start/stop command. Logic 1 = start,

logic 0 = stop.

[9] Latched

start

If a pulse is applied for minimum 2 ms, the

motor starts. The motor stops when stop

inverse is activated, or a reset command (via

DI) is given.

[10] Reversing (Default digital input 19). Change the direction

of motor shaft rotation. Select logic 1 to

reverse. The reversing signal only changes the

direction of rotation. It does not activate the

start function. Select both directions in

parameter 4-10 Motor Speed Direction. The

function is not active in process closed loop.

[11] Start

reversing

Used for start/stop and for reversing on the

same wire. Signals on start are not allowed at

the same time.

[12] Enable

start

forward

Disengages the counterclockwise movement

and allows clockwise direction.

[13] Enable

start

reverse

Disengages the clockwise movement and

allows counterclockwise direction.

[14] Jog (Default digital input 29): Activate jog speed.

See parameter 3-11 Jog Speed [Hz].

[15] Preset

reference

on

Shifts between external reference and preset

reference. It is assumed that [1] External/preset

has been selected in parameter 3-04 Reference

Function. Logic 0 = external reference active;

logic 1 = 1 of the 8 preset references is active.

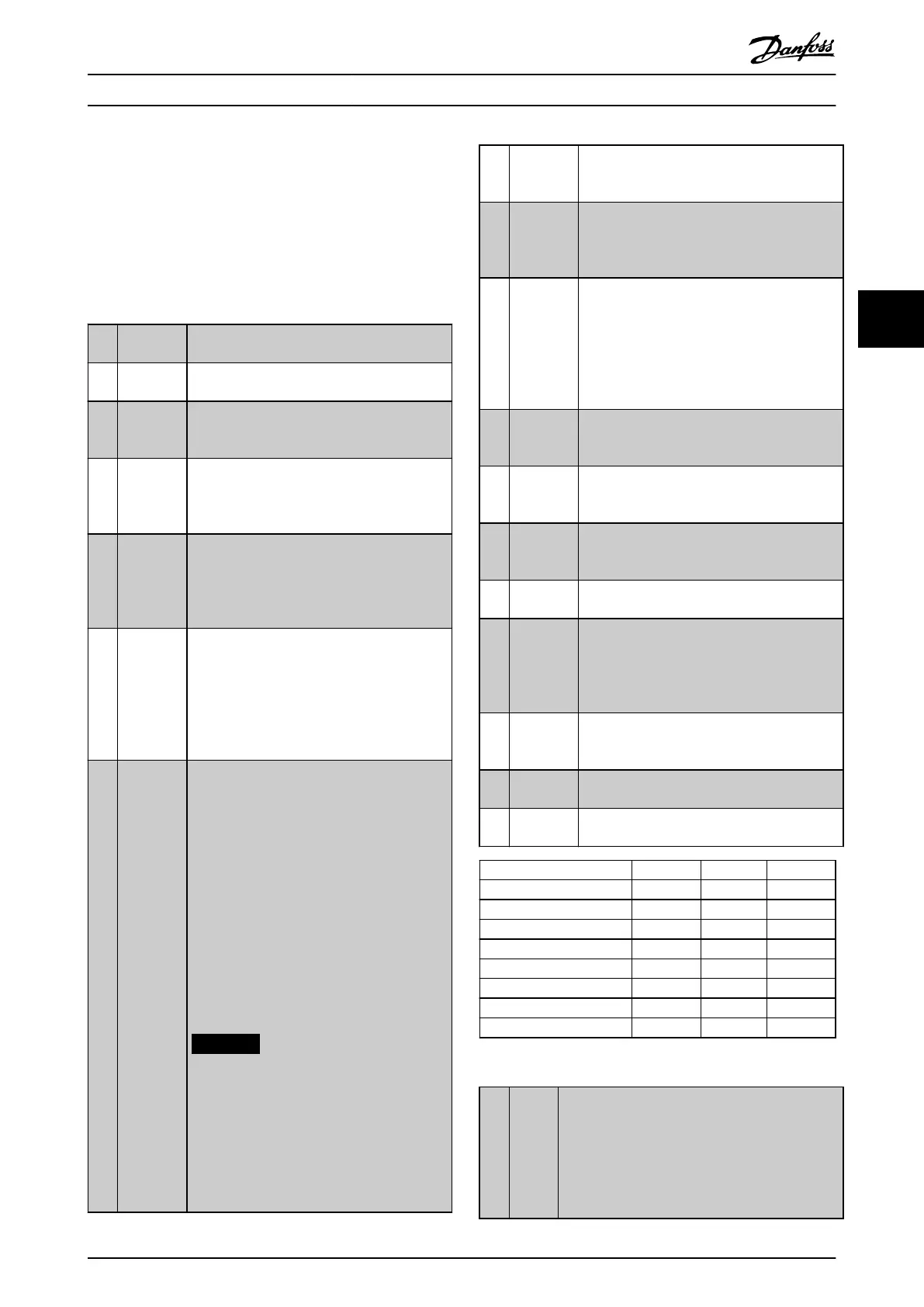

[16] Preset ref

bit 0

Preset reference bit 0, 1, and 2 enable a choice

between 1 of the 8 preset references according

to Table 4.9.

[17] Preset ref

bit 1

Same as [16] Preset ref bit 0.

[18] Preset ref

bit 2

Same as [16] Preset ref bit 0.

Preset ref. bit 2 1 0

Preset ref. 0 0 0 0

Preset ref. 1 0 0 1

Preset ref. 2 0 1 0

Preset ref. 3 0 1 1

Preset ref. 4 1 0 0

Preset ref. 5 1 0 1

Preset ref. 6 1 1 0

Preset ref. 7 1 1 1

Table 4.9 Preset Reference Bit

[19] Freeze

ref

Freezes the actual reference, which is now the

point of enable/condition to be used for [21] Speed

up and [22] Speed down. If speed up/speed down

is used, the speed change always follows ramp 2

(parameter 3-51 Ramp 2 Ramp Up Time and

parameter 3-52 Ramp 2 Ramp Down Time) in the

range 0–parameter 3-03 Maximum Reference.

Parameter Descriptions Programming Guide

MG06J202 Danfoss A/S © 03/2019 All rights reserved. 67

4 4

Loading...

Loading...