When using a drive to reduce fan capacity to 60% - more than 50% energy savings may be obtained in typical applications.

3.1.1.2 Example of Energy Savings

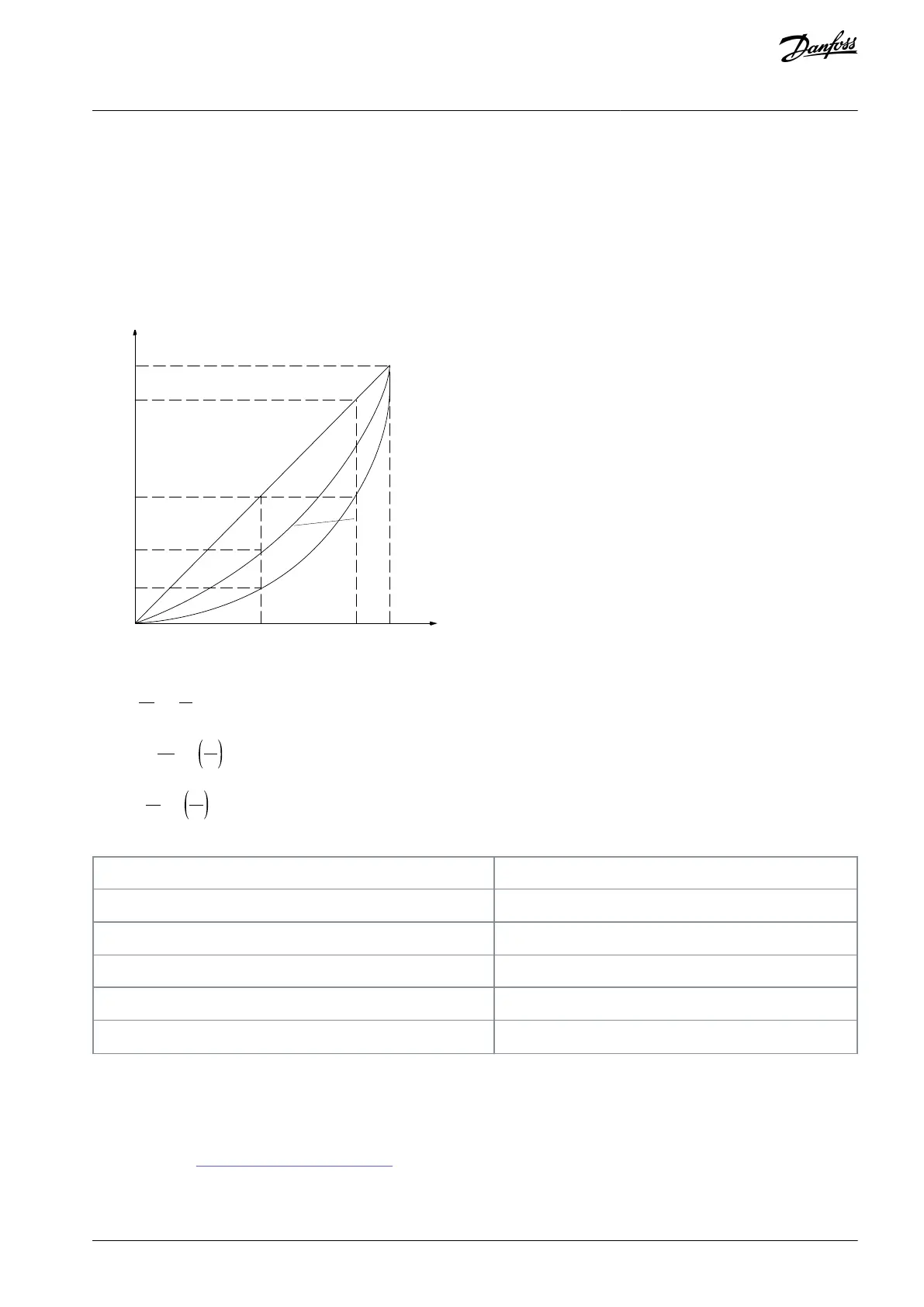

As shown in the following illustration, the flow is controlled by changing the RPM. By reducing the speed by only 20% from the

rated speed, the flow is also reduced by 20%. This is because the flow is directly proportional to the RPM. The consumption of elec-

tricity, however, is reduced by 50%.

If the system in question only needs to be able to supply a flow that corresponds to 100% a few days in a year, while the average is

below 80% of the rated flow for the remainder of the year, the amount of energy saved is even more than 50%.

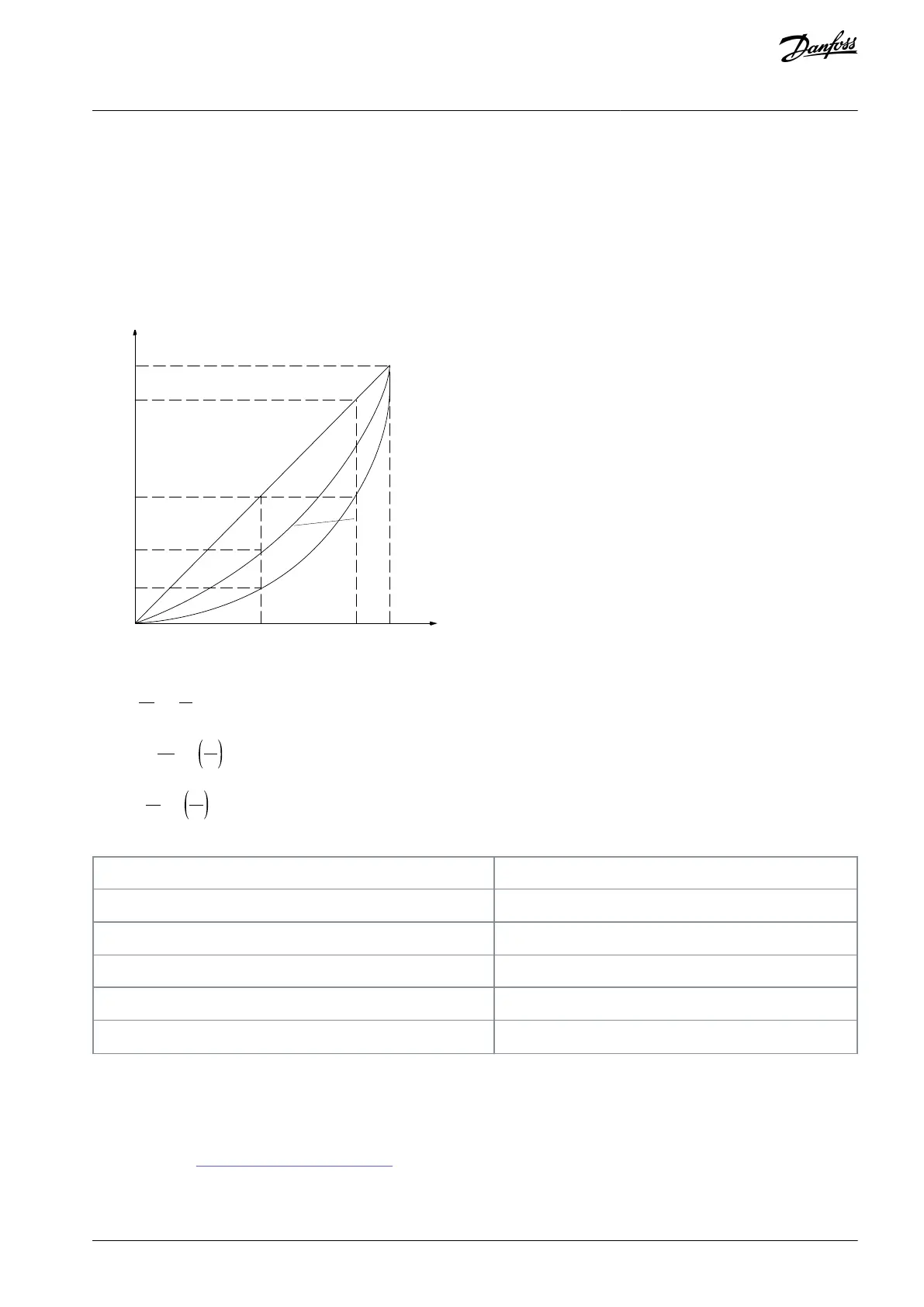

The following illustration describes the dependence of flow, pressure, and power consumption on RPM.

80%

e75ha208.10

P o w er ~n

3

P r essur e ~n

2

Illustration 3: Laws of Proportionally

Flow:

Q

1

Q

2

=

n

1

n

2

Pressure:

H

1

H

2

=

n

1

n

2

2

Power:

P

1

P

2

=

n

1

n

2

3

Table 4: The Laws of Proportionality

3.1.1.3 Comparison of Energy Savings

The Danfoss drive solution offers major savings compared with traditional energy saving solutions such as discharge damper solu-

tion and inlet guide vanes (IGV) solution. This is because the drive is able to control fan speed according to thermal load on the

system, and the drive has a built-in facility that enables the drive to function as a building management system, BMS.

The illustration in 3.1.1.2 Example of Energy Savings shows typical energy savings obtainable with 3 well-known solutions when fan

volume is reduced to 60%. As the graph shows, more than 50% energy savings can be achieved in typical applications.

AJ363928382091en-000101 / 130R0983 | 15Danfoss A/S © 2021.04

Product Overview

VLT® Flow Drive FC 111

Design Guide

Loading...

Loading...