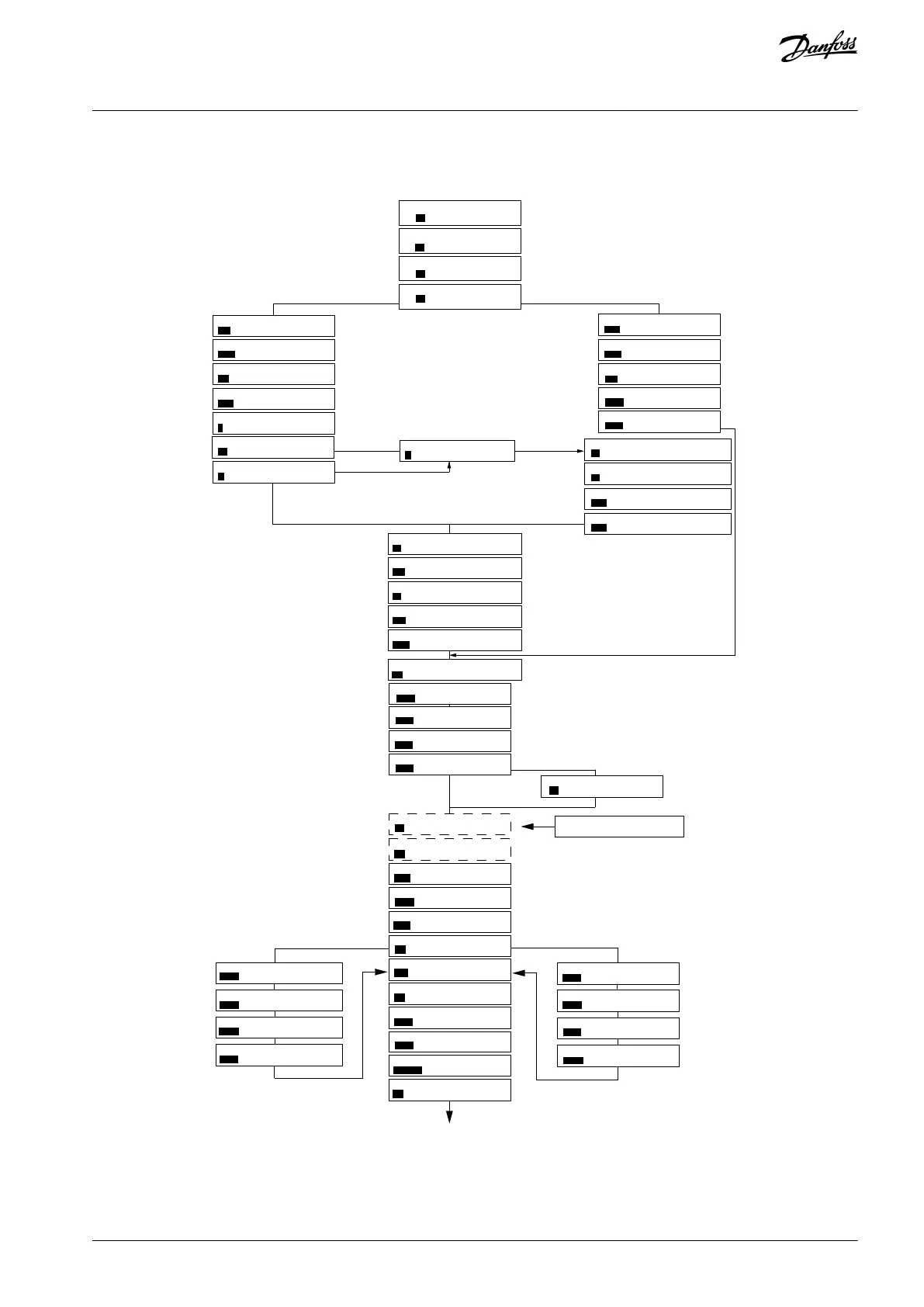

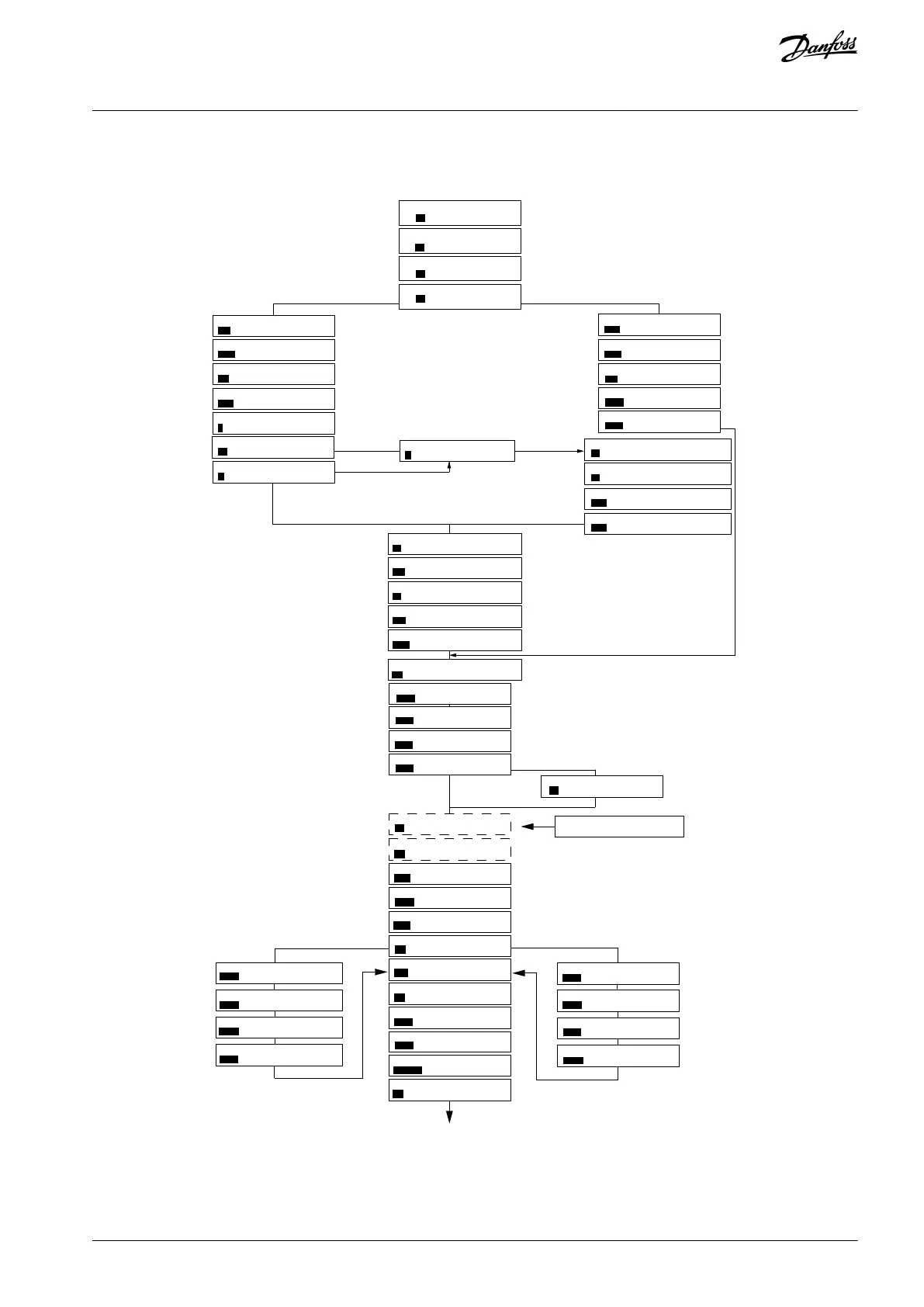

7.2.2.4 Setup Wizard for Closed-loop Applications

6-29 Terminal 54 Mode

[1]

Voltage

6-25 T54 high Feedback

0050

Hz

20-94 PI integral time

0020.00

s

Current

Voltage

This dialog is forced to be set to

[1] Analog input 54

20-00 Feedback 1 source

[1]

Analog input 54

3-10 Preset reference [0]

0.00

3-03 Max Reference

50.00

3-02 Min Reference

0.00

Asynchronous motor

1-24 Motor Current

04.66

A

3-41 Ramp 1 ramp-up time

0010

s

3-42 Ramp1 ramp-down time

0010

s

4-12 Motor speed low limit

0016

Hz

4-14 Motor speed high limit

0050

Hz

6-22 T54 Low Current

A

6-24 T54 low Feedback

0016

Hz

6-23 T54 high Current

13.30

A

6-25 T54 high Feedback

0050

0.01

s

20-81 PI Normal/Inverse Control

[0]

Normal

20-83 PI Normal/Inverse Control

0050

Hz

20-93 PI Proportional Gain

00.50

1-29 Automatic Motor Adaption

[0]

Off

6-20 T54 low Voltage

0050

V

6-24 T54 low Feedback

0016

Hz

6-21 T54 high Voltage

0220

V

6-26

T54 Filter time const.

3-16 Reference Source 2

[0]

No Operation

[0]

200-240V/50Hz/Delta

1-30 Stator Resistance

0.65

Ohms

1-25 Motor Nominal Speed

3000

RPM

1-24 Motor Current

3.8

A

1-26 Motor Cont. Rated Torque

5.4

Nm

1-38 q-axis inductance(Lq)

5

mH

4-19 Max Ouput Frequency

0065

Hz

1-40 Back EMF at 1000 RPM

57

V

PM motor

1-39 Motor Poles

04.66

Hz

Motor type = Asynchronous

Motor type = PM motor

Motor type = IPM

Motor type = SPM

1-44 d-axis Inductance Sat. (LdSat)

(1-70) Start Mode

Rotor Detection

[0]

1-46 Position Detection Gain

%

Off

100

30-22 Locked Rotor Detection

[0]

s

30-23 Locked Rotor Detection Time[s]

0.10

5

mH

1-42 Motor Cable Length

50

m

(1-45) q-axis Inductance Sat. (LqSat)

(1-48) Current at Min Inductanc e for d-axis

100

%

1-49 Current at Min Inductanc e for q-axis

%

1-37 d-axis inductance(Lq)

5

mH

Illustration 62: Setup Wizard for Closed-loop Applications

AJ363928382091en-000101 / 130R0983 | 89Danfoss A/S © 2021.04

Programming

VLT® Flow Drive FC 111

Design Guide

Loading...

Loading...