•

•

•

•

•

-

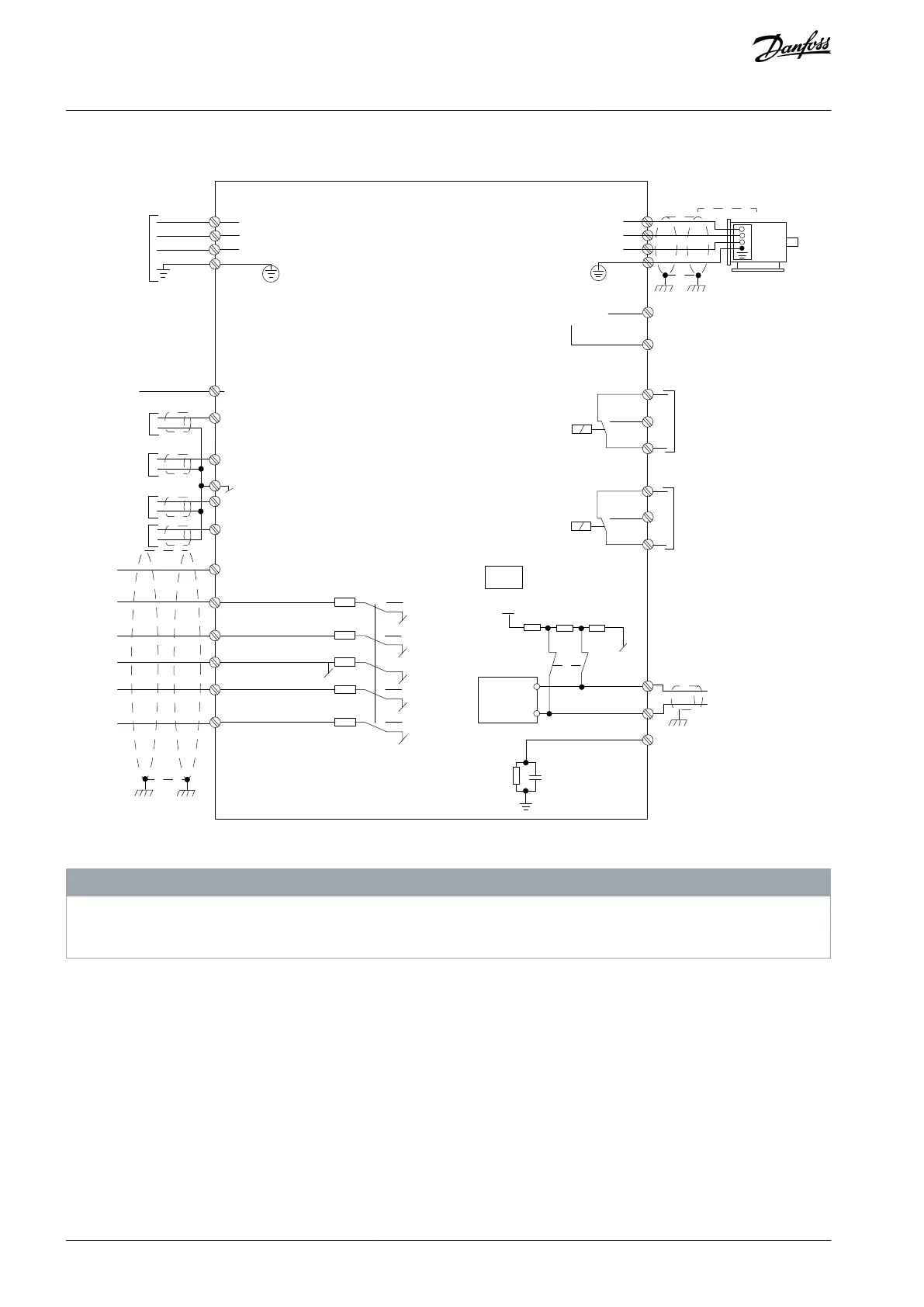

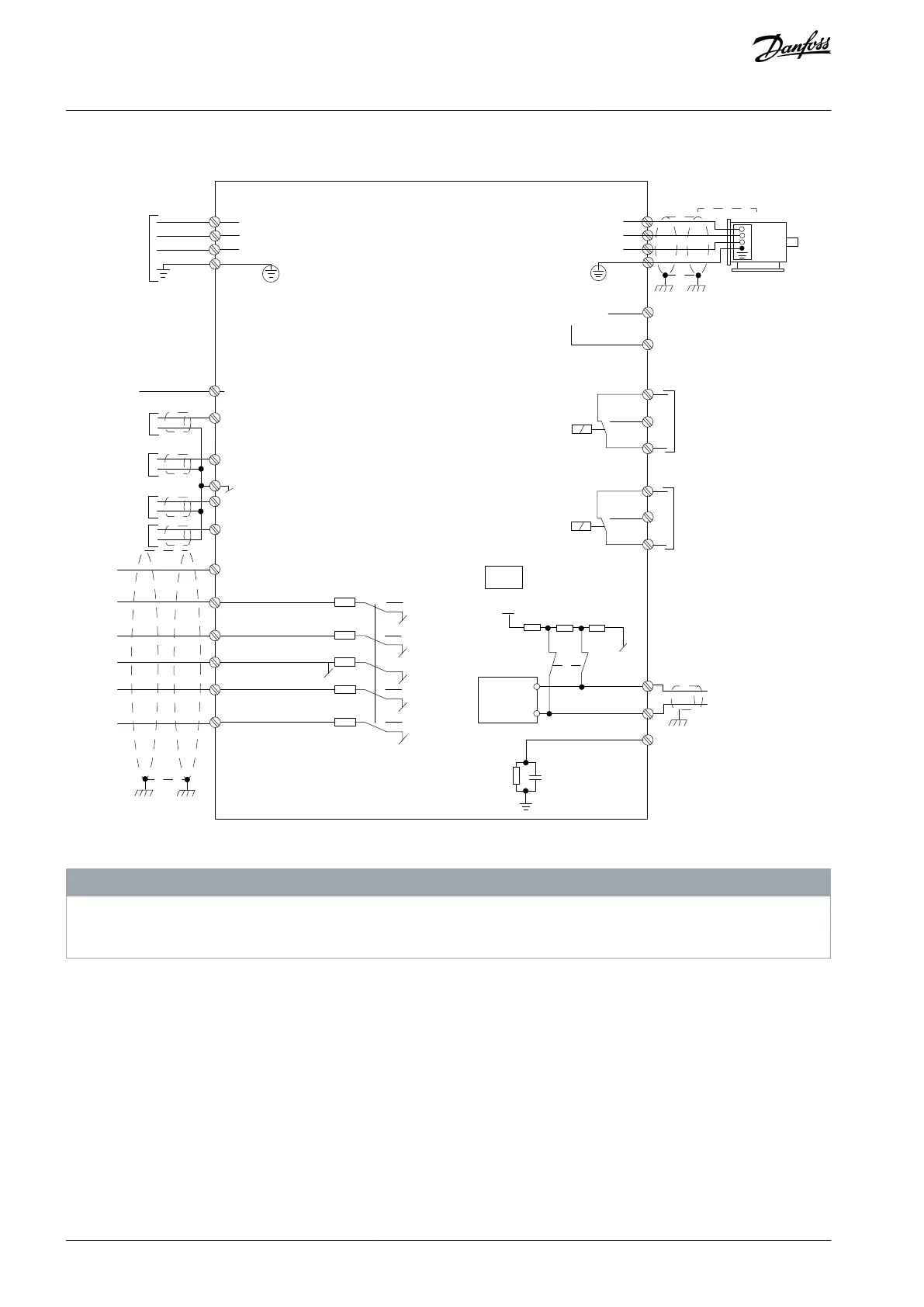

6.2 Electrical Wiring

+10 V DC

0-10 V DC-

0-10 V DC-

50 (+10 V OUT)

54 (A IN)

53 (A IN)

55 (COM A IN/OUT)

42 0/4-20 mA A OUT / D OUT

45 0/4-20 mA A OUT / D OUT

18 (D IN)

19 (D IN)

27 (D IN/OUT)

29 (D IN/OUT)

12 (+24 V OUT)

24 V (NPN)

20 (COM D IN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

Bus ter.

Bus ter.

RS485

Interface

RS485

(N RS485) 69

(P RS485) 68

(Com RS485 ) 61

(PNP)-Source

(NPN)-Sink

ON=Terminated

OFF=Unterminated

ON

1 2

240 V AC 3 A

Not present on all power sizes

Do not connect shield to 61

01

02

03

relay 1

relay 2

UDC+

UDC-

Motor

U

V

W

e30bd467.12

06

05

04

240 V AC 3 A

Illustration 46: Basic Wiring Schematic Drawing

N O T I C E

There is no access to UDC- and UDC+ on the following units:

IP20, 380–480 V, 30–315 kW (40–450 hp)

6.3 EMC-compliant Electrical Installation

To ensure EMC-correct electrical installation, observe the following:

Use only shielded/armored motor cables and shielded/armored control cables.

Ground the shield at both ends.

Avoid installation with twisted shield ends (pigtails), because it reduces the shielding effect at high frequencies. Use the cable

clamps provided.

Ensure the same potential between the drive and the ground potential of PLC.

Use star washers and galvanically conductive installation plates.

AJ363928382091en-000101 / 130R098364 | Danfoss A/S © 2021.04

Electrical Installation

Considerations

VLT® Flow Drive FC 111

Design Guide

Loading...

Loading...