5.7.3 Earthing of Screened/Armoured Control Cables

Generally speaking, control cables must be braided screened/armoured and the screen must be connected by means of a cable clamp at both ends to

the metal cabinet of the unit.

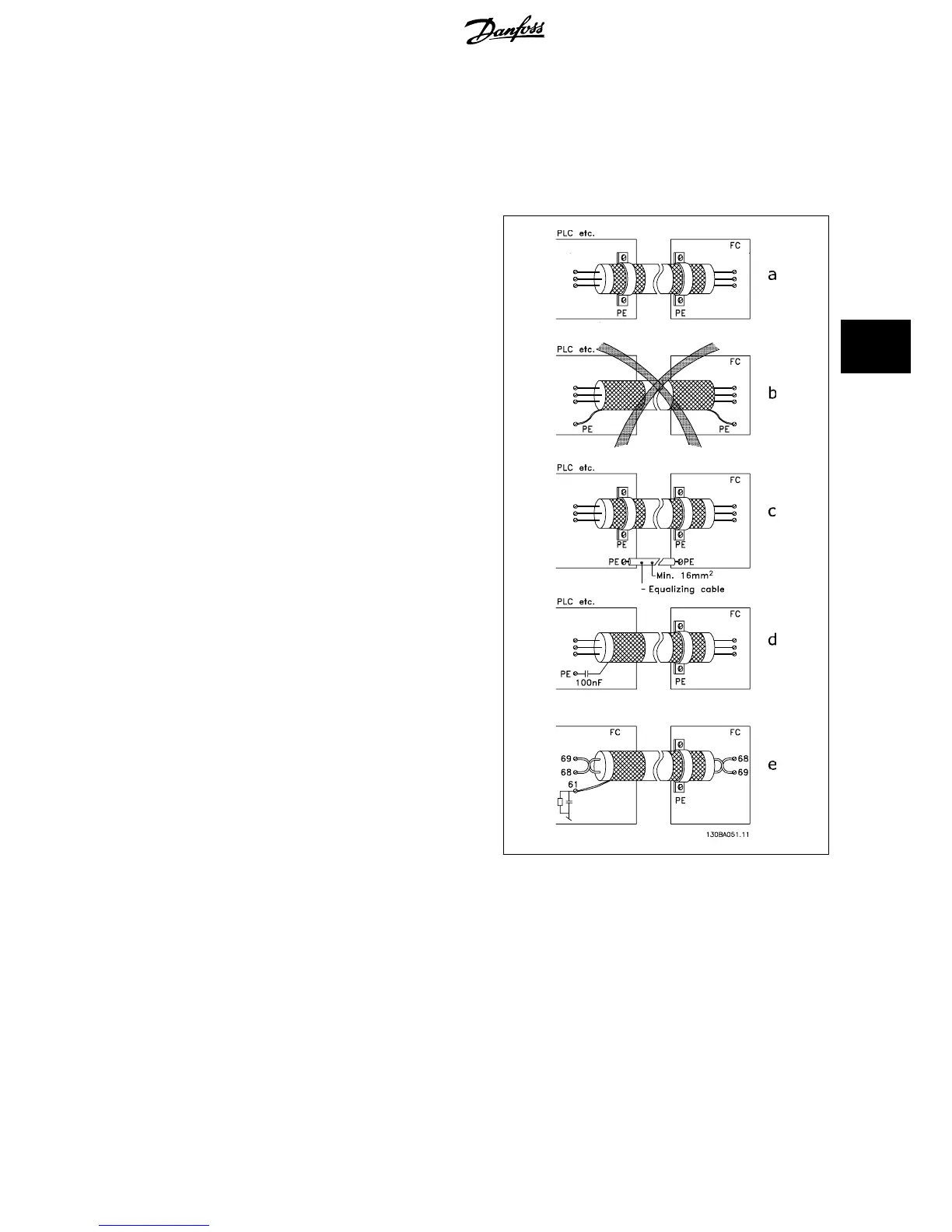

The drawing below indicates how correct earthing is carried out and what to do if in doubt.

a. Correct earthing

Control cables and cables for serial communication must be fit-

ted with cable clamps at both ends to ensure the best possible

electrical contact.

b. Wrong earthing

Do not use twisted cable ends (pigtails). They increase the

screen impedance at high frequencies.

c. Protection with respect to earth potential between PLC

and frequency converter

If the earth potential between the frequency converter and the

PLC (etc.) is different, electric noise may occur that will disturb

the entire system. Solve this problem by fitting an equalising

cable, next to the control cable. Minimum cable cross-section:

16 mm

2

.

d. For 50/60 Hz earth loops

If very long control cables are used, 50/60 Hz earth loops may

occur. Solve this problem by connecting one end of the screen

to earth via a 100nF capacitor (keeping leads short).

e. Cables for serial communication

Eliminate low-frequency noise currents between two frequency

converters by connecting one end of the screen to terminal 61.

This terminal is connected to earth via an internal RC link. Use

twisted-pair cables to reduce the differential mode interference

between the conductors.

5.8.1 Residual Current Device

You can use RCD relays, multiple protective earthing or earthing as extra protection, provided that local safety regulations are complied with.

If an earth fault appears, a DC content may develop in the faulty current.

If RCD relays are used, you must observe local regulations. Relays must be suitable for protection of 3-phase equipment with a bridge rectifier and for

a brief discharge on power-up see section

Earth Leakage Current

for further information.

VLT

®

HVAC Drive Design Guide 5 How to Install

MG.11.B9.02 - VLT

®

is a registered Danfoss trademark

117

5

Loading...

Loading...