5.2 Electrical Installation

5.2.1 Cables general

NB!

For the VLT HVAC Drive High Power series mains and motor connections, please see VLT HVAC Drive

High Power Operating Instruc-

tions

MG.11.FX.YY

.

NB!

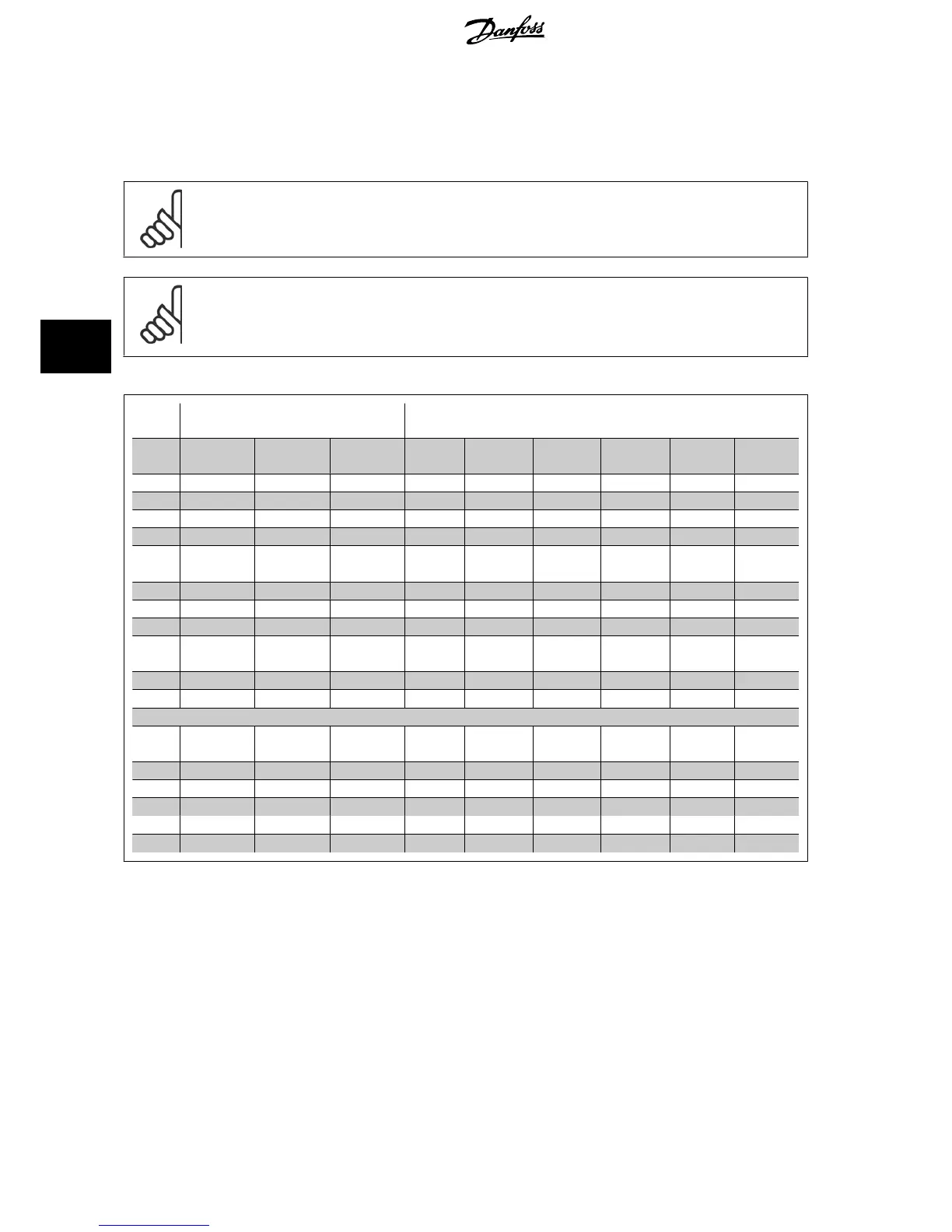

Cables General

All cabling must comply with national and local regulations on cable cross-sections and ambient temperature. Copper (60/75 °C)

conductors are recommended.

Details of terminal tightening torques.

Power (kW) Torque (Nm)

Enclo-

sure

200-240

V

380-480

V

525-600

V

Mains Motor

DC connec-

tion

Brake Earth Relay

A2 1.1 - 3.0 1.1 - 4.0 1.1 - 4.0 1.8 1.8 1.8 1.8 3 0.6

A3 3.7 5.5 - 7.5 5.5 - 7.5 1.8 1.8 1.8 1.8 3 0.6

A5 1.1 - 3.7 1.1 - 7.5 1.1 - 7.5 1.8 1.8 1.8 1.8 3 0.6

B1 5.5 - 11 11 - 18.5 - 1.8 1.8 1.5 1.5 3 0.6

B2

-

15

22

30

-

-

4.5

4.5

2)

4.5

4.5

2)

3.7

3.7

3.7

3.7

3

3

0.6

0.6

B3 5.5 - 11 11 - 18.5 11 - 18.5 1.8 1.8 1.8 1.8 3 0.6

B4 11 - 18.5 18.5 - 37 18.5 - 37 4.5 4.5 4.5 4.5 3 0.6

C1 18.5 - 30 37 - 55 - 10 10 10 10 3 0.6

C2 37 - 45 75 - 90

-

-

14/24

1)

14/24

1)

14 14 3 0.6

C3 18.5 - 30 37 - 55 37 - 55 10 10 10 10 3 0.6

C4 30 - 45 55 - 90 55 - 90

14/24

1)

14/24

1)

14 14 3 0.6

High Power

Enclo-

sure

380-480

V

525-690

V

Mains Motor

DC connec-

tion

Brake Earth Relay

D1/D3 110-132 45-160 19 19 9.6 9.6 19 0.6

D2/D4 160-250 200-400 19 19 9.6 9.6 19 0.6

E1/E2 315-450 450-630 19 19 19 9.6 19 0.6

F1-F3

3)

500-710

710-900 19 19 19 9.6 19 0.6

F2-F4

3)

800-1000

1000-1400 19 19 19 9.6 19 0.6

Table 5.2: Tightening of terminals

1) For different cable dimensions x/y, where x ≤ 95 mm² and y ≥ 95 mm²

2) Cable dimensions above 18.5 kW ≥ 35 mm

2

and below 22 kW ≤ 10 mm

2

3) For data on the F-series please consult VLT HVAC Drive High Power Operating Instructions, MG.11.F1.02

5 How to Install VLT

®

HVAC Drive Design Guide

88

MG.11.B9.02 - VLT

®

is a registered Danfoss trademark

5

Loading...

Loading...