EtherNet/IP Operation Manual

1-2

1.1 Introduction

1.1.1 EtherNet/IP

EtherNet/IP (“IP” stands for “Industrial Protocol”) is an industrial Ethernet network managed by ODVA, Inc. (formerly Open

DeviceNet Vendors Association, Inc.), a global trade and standards development organization.

EtherNet/IP works on a TCP/UDP/IP based Ethernet network and uses most widely deployed collections of Ethernet

standards to provide a broad range of applications in different industries that require high-speed and stability including

Factory Automation (FA), Building Automation (BA), Process Automation (PA) and many more.

Delta covers a full range of controller and drive products supported by EtherNet/IP, including Programmable Logic

Controllers (PLC), inverters, Human Machine Interfaces (HMI) and so on. Refer to section 9.1 for a full product list

supported by EtherNet/IP. In addition, users can also use the EDS file to connect to the EtherNet/IP devices of other

brands. Delta EtherNet/IP software, the EIP Builder, can be called or run independently through the ISPSoft v3.06.

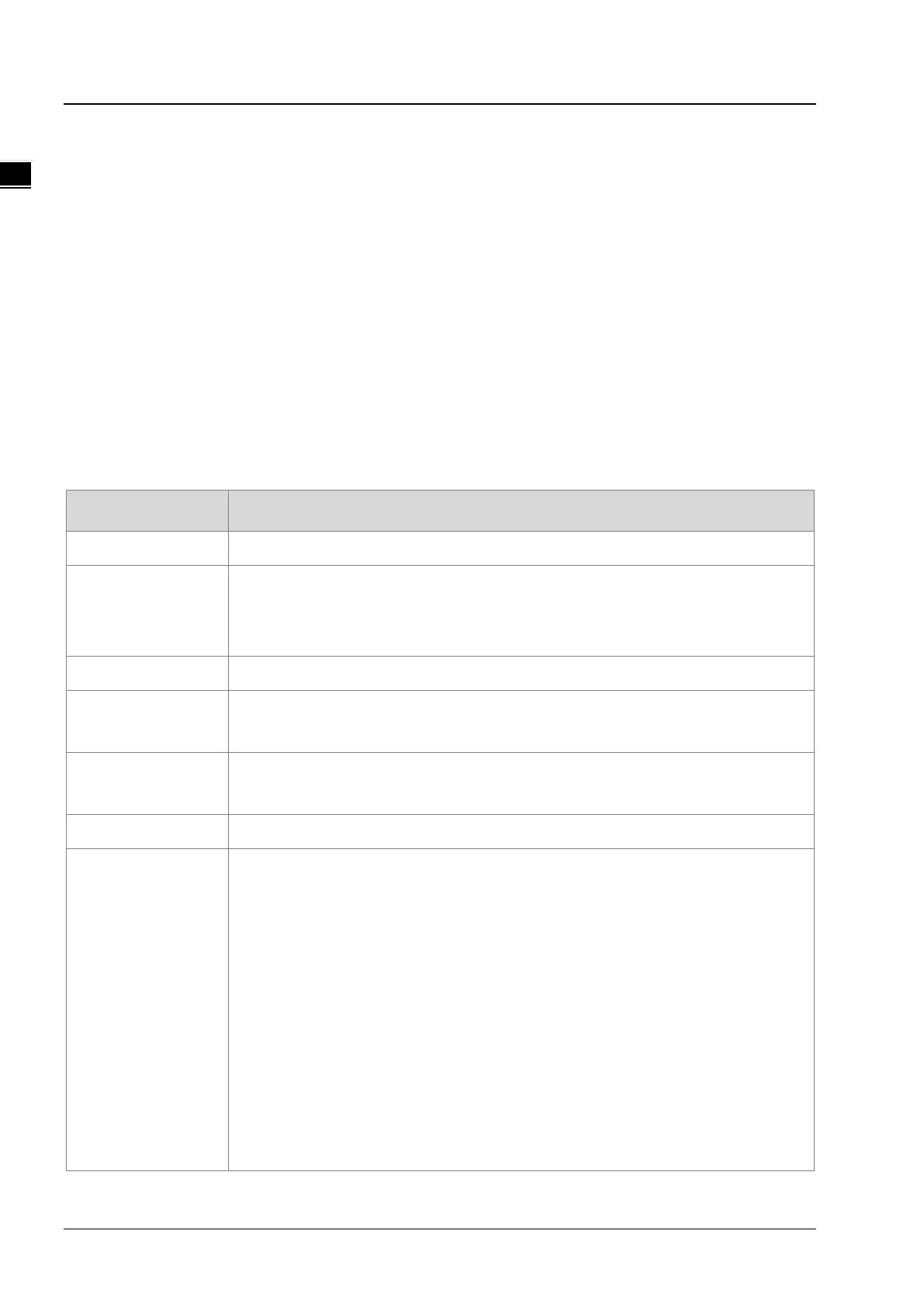

1.2 Definition

Term Definition

ODVA Open DeviceNet Vendor Association for EtherNet/IP

EIP

EtherNet/IP, an industrial Ethernet network, provides interoperability for system providers. IP

stands for Industrial Protocol. The term “EIP” (EtherNet/IP) will be used throughout this

manual.

I/O Connection Via the I/O connection to connect to EtherNet/IP and to exchange data cyclically.

Explicit Message

Connect to EtherNet/IP and to exchange data non-cyclically. Data will be exchanged piece

by piece via instructions.

RPI

Requested Packet Interval, via the I/O connection to connect to EtherNet/IP to exchange

data at regular time intervals.

ACD Address Conflict Detection to detect IP address duplications.

Produced/Consumed

TAG (P/C TAG)

TAGs are the methods used for assigning and referencing memory locations for

Rockwell PLCs, the same as the registers for Delta PLCs.

Produced TAG: A TAG that a controller makes available for other controllers. Multiple

controllers can simultaneously consume (receive) the data. A produced TAG sends its

data to consumed TAGs (consumers) without using logic.

Consumed TAG: A TAG that receives the data of a produced TAG. The data type of the

consumed TAG and the produced TAG must be matched (including any array

dimensions).

The data is transferred over Ethernet/IP, for example, PLC-A needs data from PLC-B,

so PLC-B sends the data to PLC-A. Therefore, PLC-A is the producer and PLC-B is

the consumer.

Loading...

Loading...