ASDA-A2 Chapter 8 Parameters

Revision February, 2017 8-133

Unit:

N/A

Range:

0000h ~ 0xFF7D

Data Size:

16-bit

Format:

Hexadecimal

Settings:(This function is available in firmware version V1.038 sub54 and

later models)

X: Pulse masking function of master axis / JOG function of master axis

/ INCH function of master axis

Y: Correction of lead command length for pulse masking

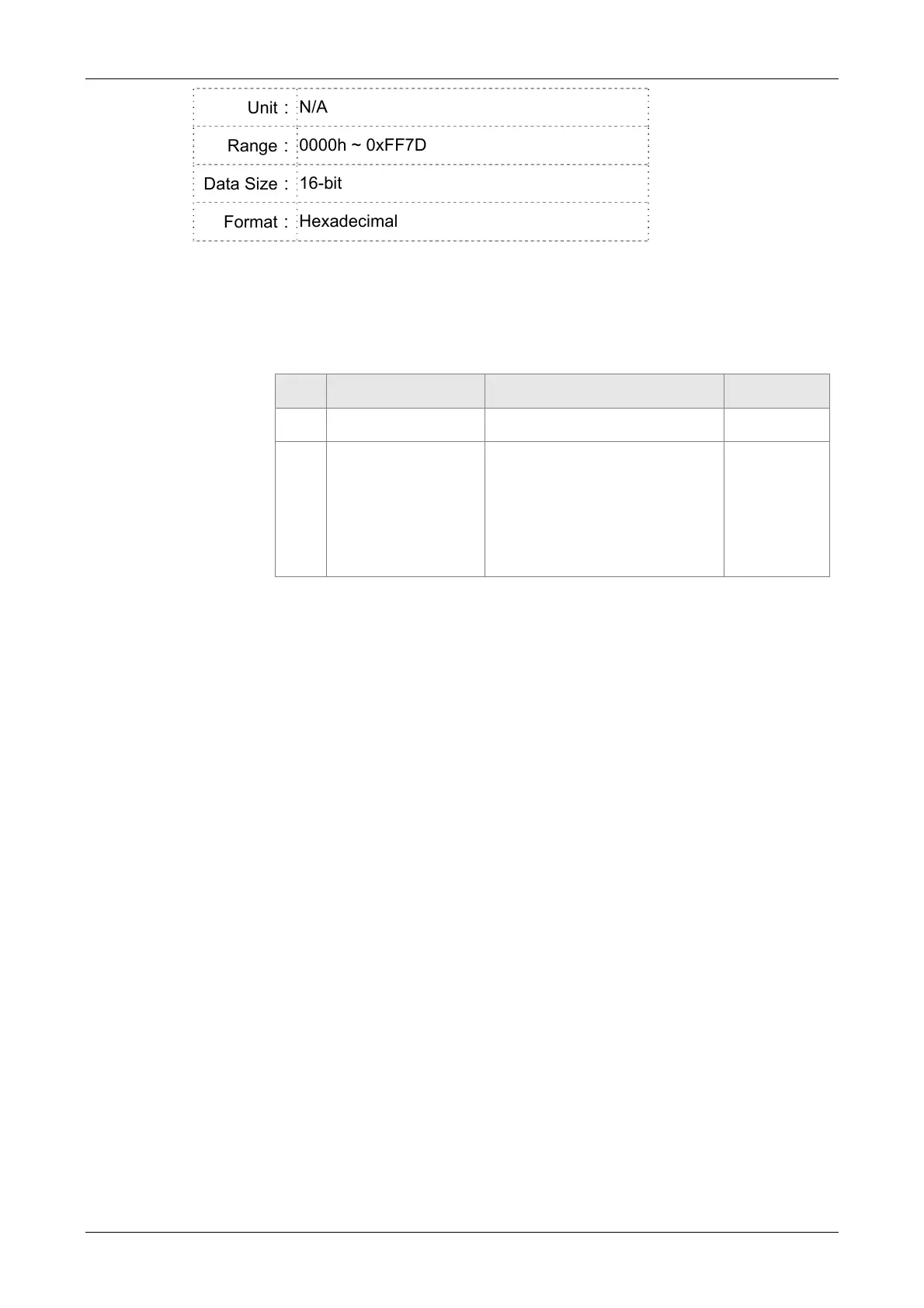

Y3 Y2 Y1 Y0

-

Extra 1 Cycle Write to ROM CALC

- Calculate the value

of P5-87 and plus a

cycle of a resolution

of pulse command,

i.e. (P5-84/P5-83).

Calculate the value of P5-87

and write the value of P5-87

into EEPROM at the same time

to ensure the correct position of

E-Cam after the servo drive is

restarted (after switching power

off and on).

Calculate

the value of

P5-87.

Y=0 1: Calculate the value of P5-87 correctly according to actual

masking pulse number and additional virtual pulse number.

Y=0 2: Calculate the value of P5-87 correctly according to

actual masking pulse number and additional virtual pulse

number. Then, write the revised value of P5-87 into

EEPROM to keep the same phase after the servo drive is

restarted.

Y=0 7: Calculate the value of P5-87 correctly according to actual

masking pulse number and additional virtual pulse number.

But, the revised value of P5-87 will plus a value of (P5-84/P5-

83) to make lead pulse wait for an E-Cam cycle.

UZ: Pulse data when the master axis performs JOG or INCH

function

For example:

Start masking UZYX = 0x0001

JOG +3Kpps UZYX = 0x0302

JOG +20Kpps UZYX = 0x1402

JOG -32Kpps UZYX = 0x2003

INCH +255 PLS UZYX = 0xFF04

INCH -18 PLS UZYX = 0x1205

Complete and correct lead pulse UZYX = 0x0020 (Write into

EEPROM)

Disable this function UZYX = 0x0000 (This step can be ignored)

Loading...

Loading...