Chapter 7 Optional AccessoriesC2000

7-4

Table 7-4

Table 7-5

Applicable

Motor (kW)

*

1

125% Braking Torque / 10%ED *

2

Max. Braking Torque

LD ND HD

Braking

Torque

[kg-m]

Brake

Unit

VFDB

*

3

Braking Resistor series for

each Brake Unit

Resistor value

spec. for each

AC motor drive

Total

Braking

Current

[A]

Min.

Resistor

Value

[Ω]

Max.

Total

Braking

Current

[A]

Peak

Power

[kW]

450 355 315 240.3 6200*2 BR1K5W027*14

2 series,

7 parallel

42000W 3.9Ω 290.4 3.5 324 362.9

560 450 355 304.7 6200*3 BR1K5W027*12

2 series,

6 parallel

54000W 3.0Ω 373.3 2.3 486 544.3

630 630 630 426.5 6200*4 BR1K5W027*12

2 series,

6 parallel

72000W 2.3Ω 497.8 1.7 648 725.8

*1.

Calculation for 125% brake toque: (kW) * 125% * 0.8; where 0.8 is motor efficiency.

Because of the limited resistor power, the longest operation time for 10% ED is 10 seconds (on: 10 seconds / off: 90 seconds).

*2.

Refer to Chapter 7 “Brake Module and Brake Resistors” in application manual for “Operation Duration & ED” vs. “Braking

Current”.

*3.

For heat dissipation, a resistor of 400W or lower should be fixed to the frame and maintain the surface temperature below

250°C; a resistor of 1000W and above should maintain the surface temperature below 350°C.

*4.

Please refer to VFDB series Braking Module Instruction for more detail on braking resistor.

NOTE

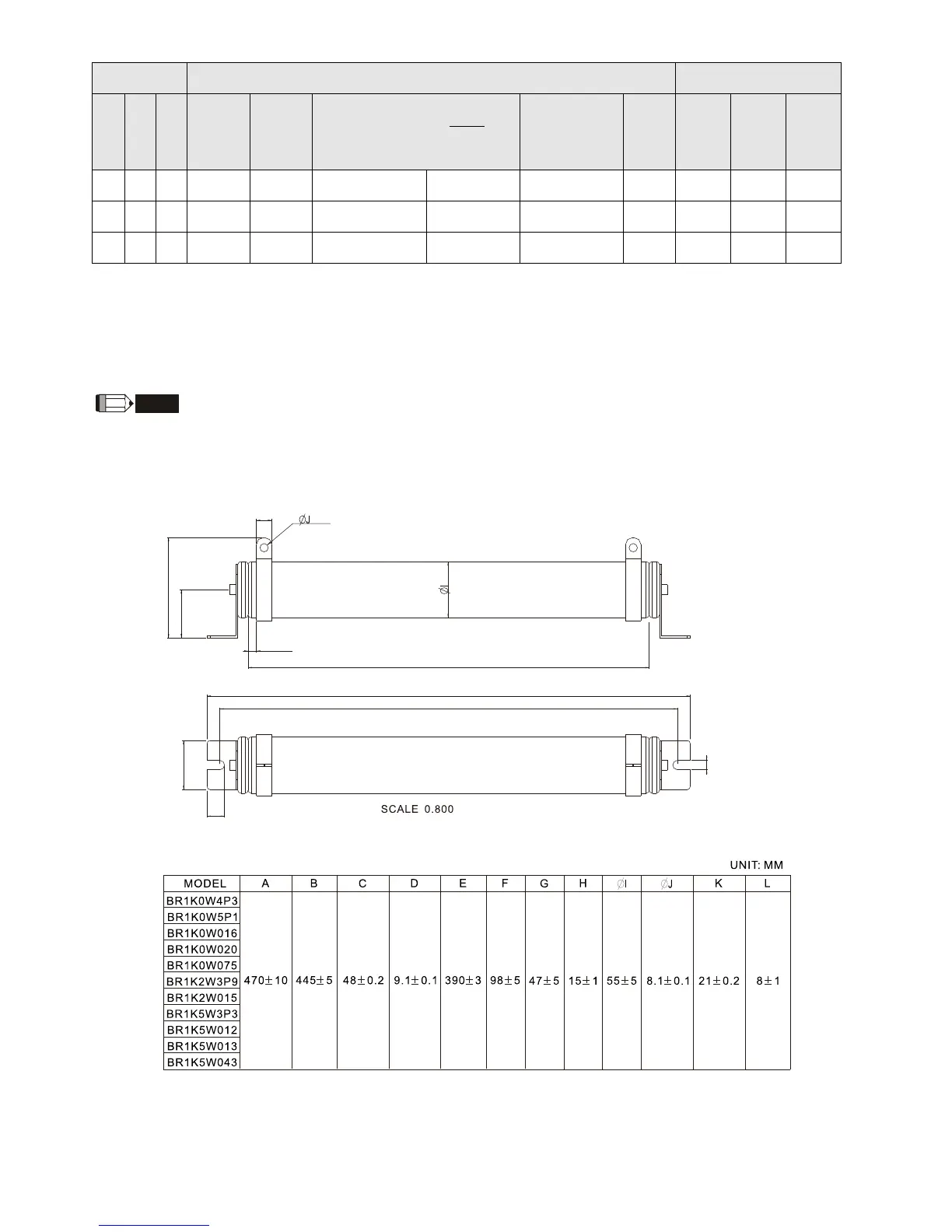

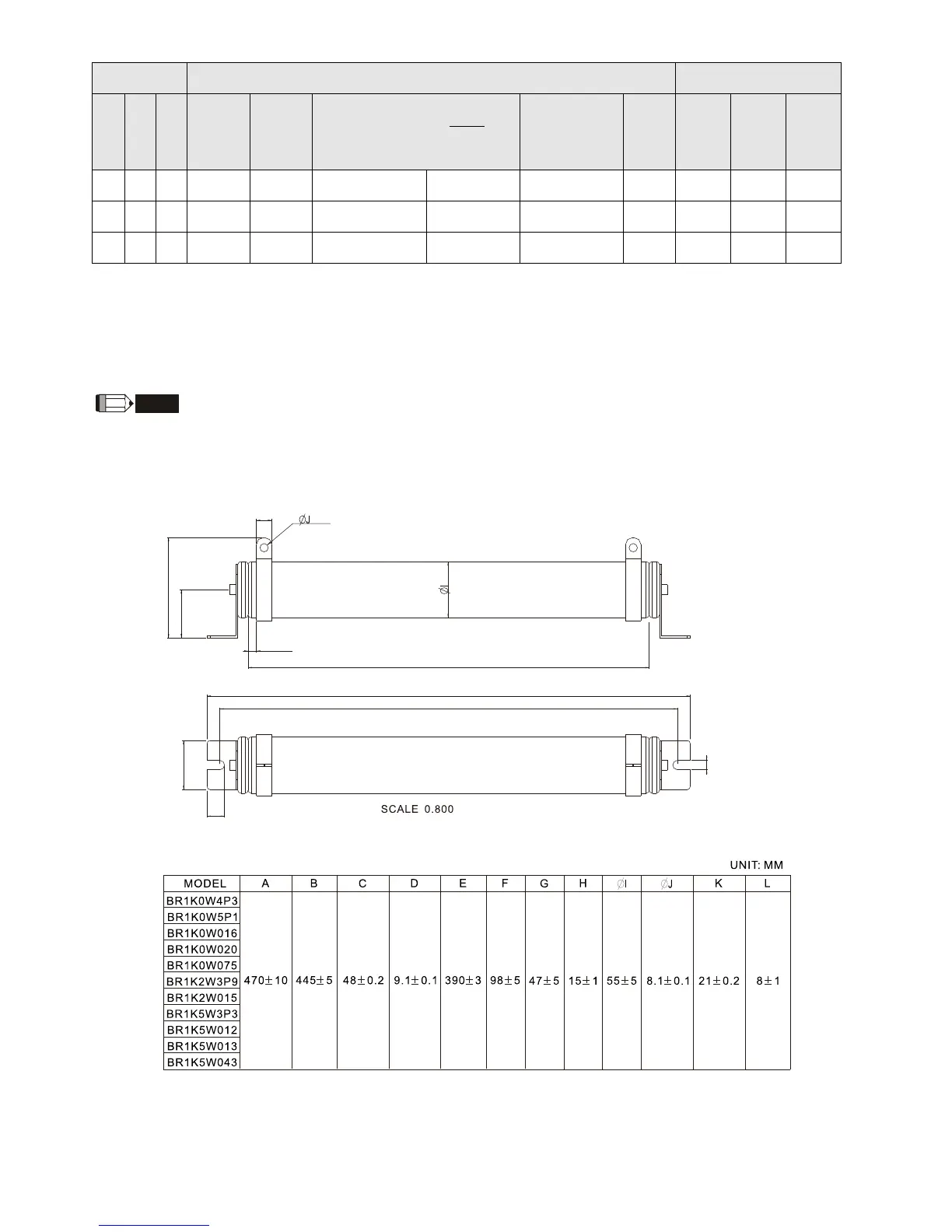

1. Specification and appearance of brake resistors

1-1 Wirewound resistor: for 1000W and above. Refer to the following appearance of wirewound resistor

(Figure7-1) and its model and specification comparison table (Table 7-5) for details.

A

B

C

D

H

F

K

G

E

L

Figure 7-1

Loading...

Loading...