ENGLISCH - Kapitel 5 - Seite 2

5

© 2004

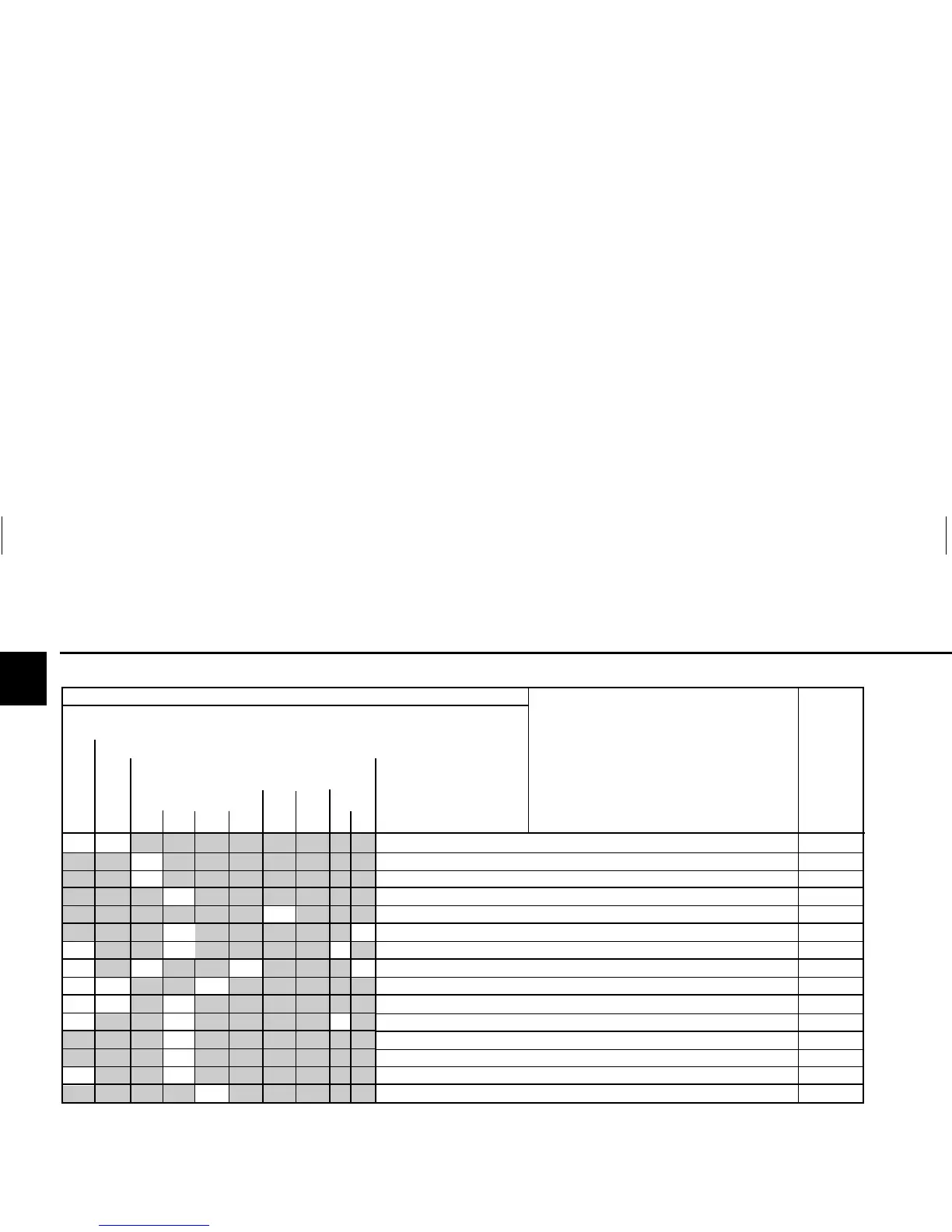

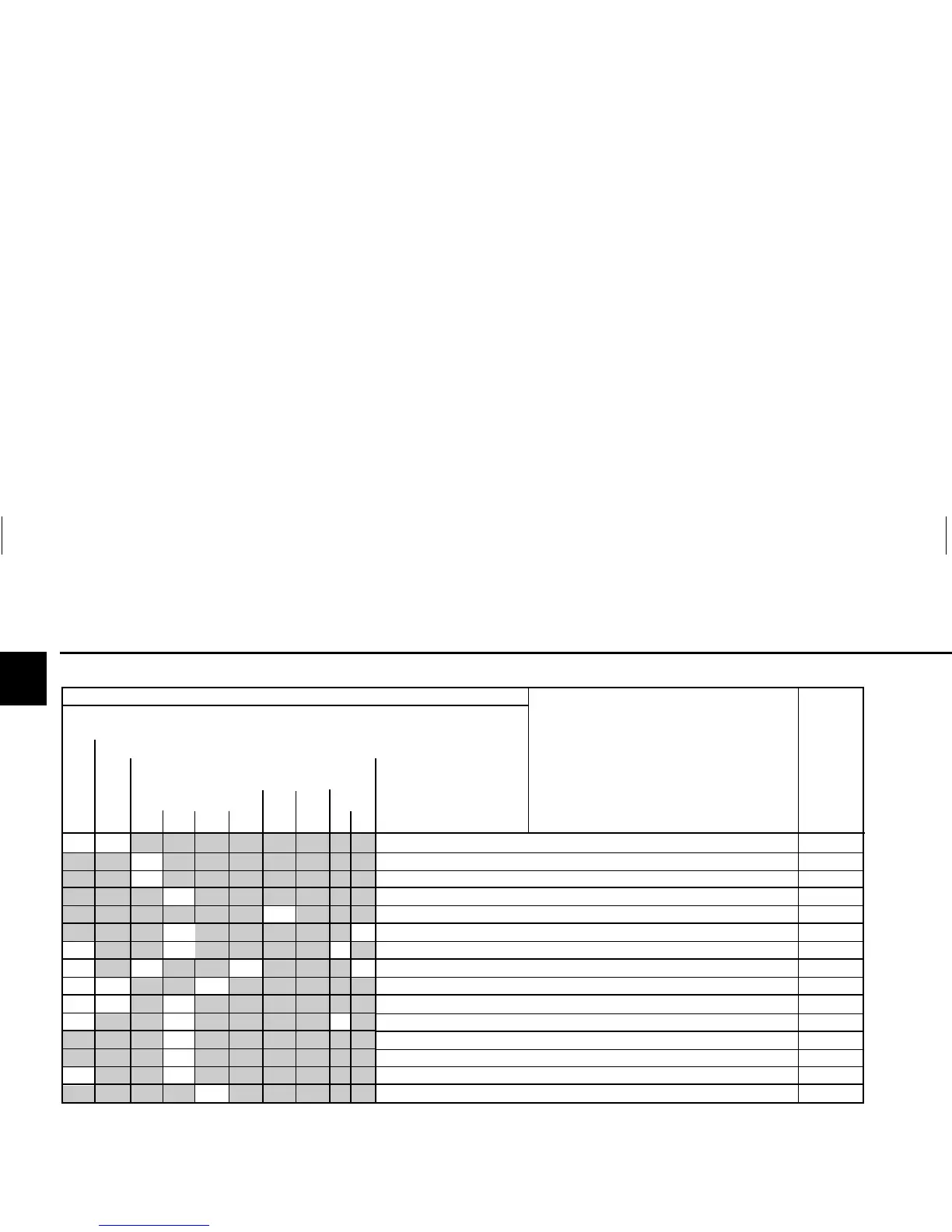

Maintenance step= E Check= ● Adjust= ❍ Clean= ▲ Replace= ■

Industrial engines

The specified engine maintenance times are

the max. permissible recommended times.

Depending on the application shorter

maintenance times may be necessary. Please

refer to manufacturer’s operating manual.

# Maintenance work to be carried out only by

authorised service personnel.

Routine Maintenance 5.1 Maintenance Schedule

Operation Section

Lube oil level, top up as necessary 6.1.2/3.1.6

Lube oil (oil changing interval acc. to engine application), see TR0199-99-3002 6.1.1/6.1.2

Oil filter cartridge (for every lube oil change) 6.1.3

Fuel filter cartridge 6.2.1

Injection valve #

Flexible fuel leakage lines (replace completely) 6.2.5

Fuel pre-filter * 4.2/ 6.2/2-4

Coolant (additive concentration) 4.3.1/ 2/ 3

Coolant liquid level/ ✔ Version with float switch, see TR0130-48-004 3.3.3

Dry/suction air filter (if present service as per maintenance display) 6.4.3 /4

Charge cooler (drain lube oil / condensate) 6.3.9

Battery and cable connections 6.7.1

Sheathed-element glow plugs –

Engine monitoring, warning system 3.3 #

Valve clearance (set if necessary, earlier if noises occur) 6.6.1#

Before or during 1st test run, during commissioning check twice

daily or when commissioning new or reconditioned engines

Every 10 operating hours or daily

In operating hours (OH), every

*E70=1012 Engines 10000OH

*E70=1013 Engines 13000OH

E10 E20 E30 E40 E50 E60 E60 E70* Years

500 1000

1500 2000

3000

*

1 2

* If the water level warning system (lamp/siren) responds, the fuel pre-filter must be emptied immediately.

1) Changing the pre-filter cartridge depends on the degree of soiling of the fuel used. If fuels which do not meet the requirements of

TR 0199-99-3005 (see 4.2.1) are used the warranty will be voided.

●●

■

■

■

●

● ■

● ■1) ■

●● ■■

●✔ ●●✔

●● ■

●

▲▲

●

●

●●

❍

9682en_k05.p65 20.09.2004, 13:242

Loading...

Loading...