OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

TROUBLESHOOTING / 43

TROUBLESHOOTING

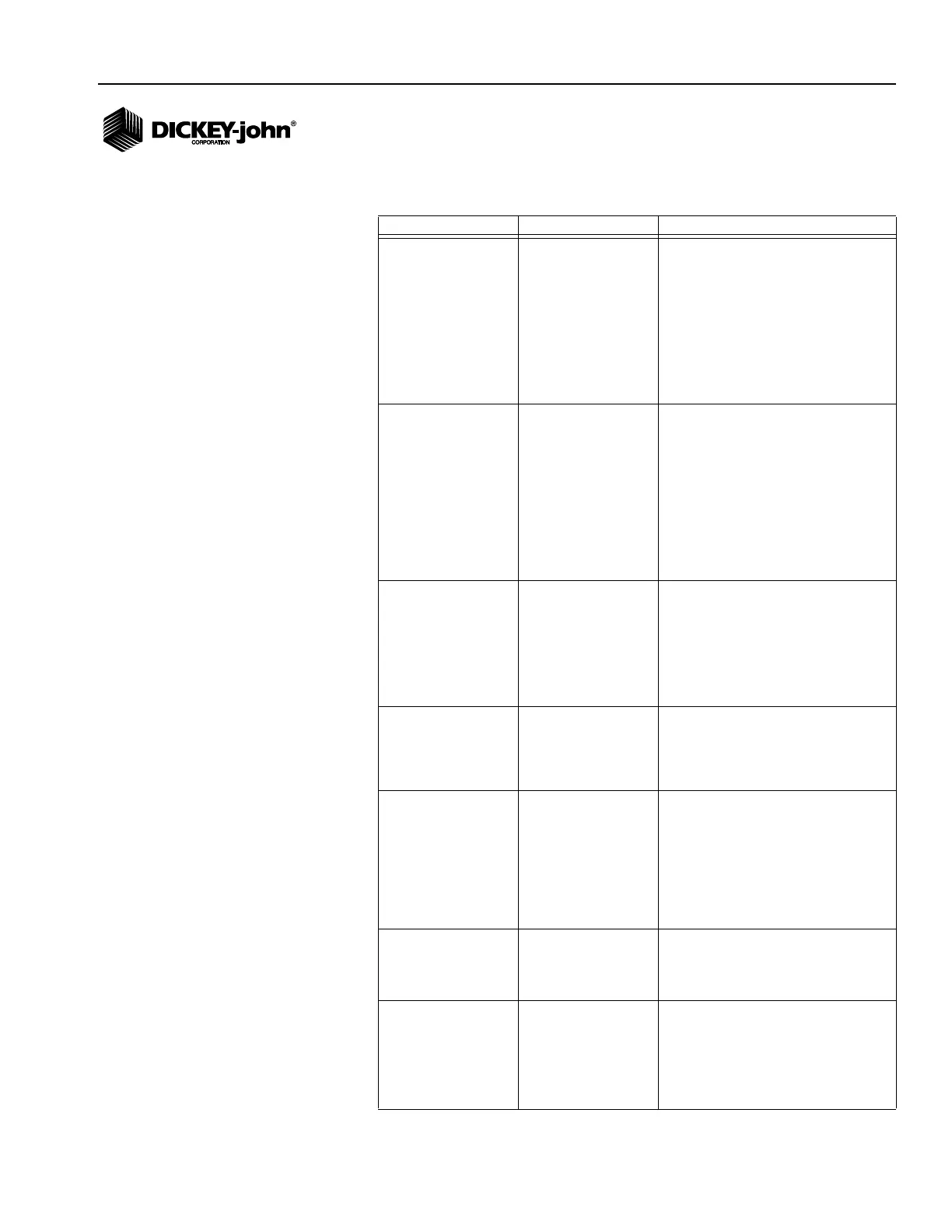

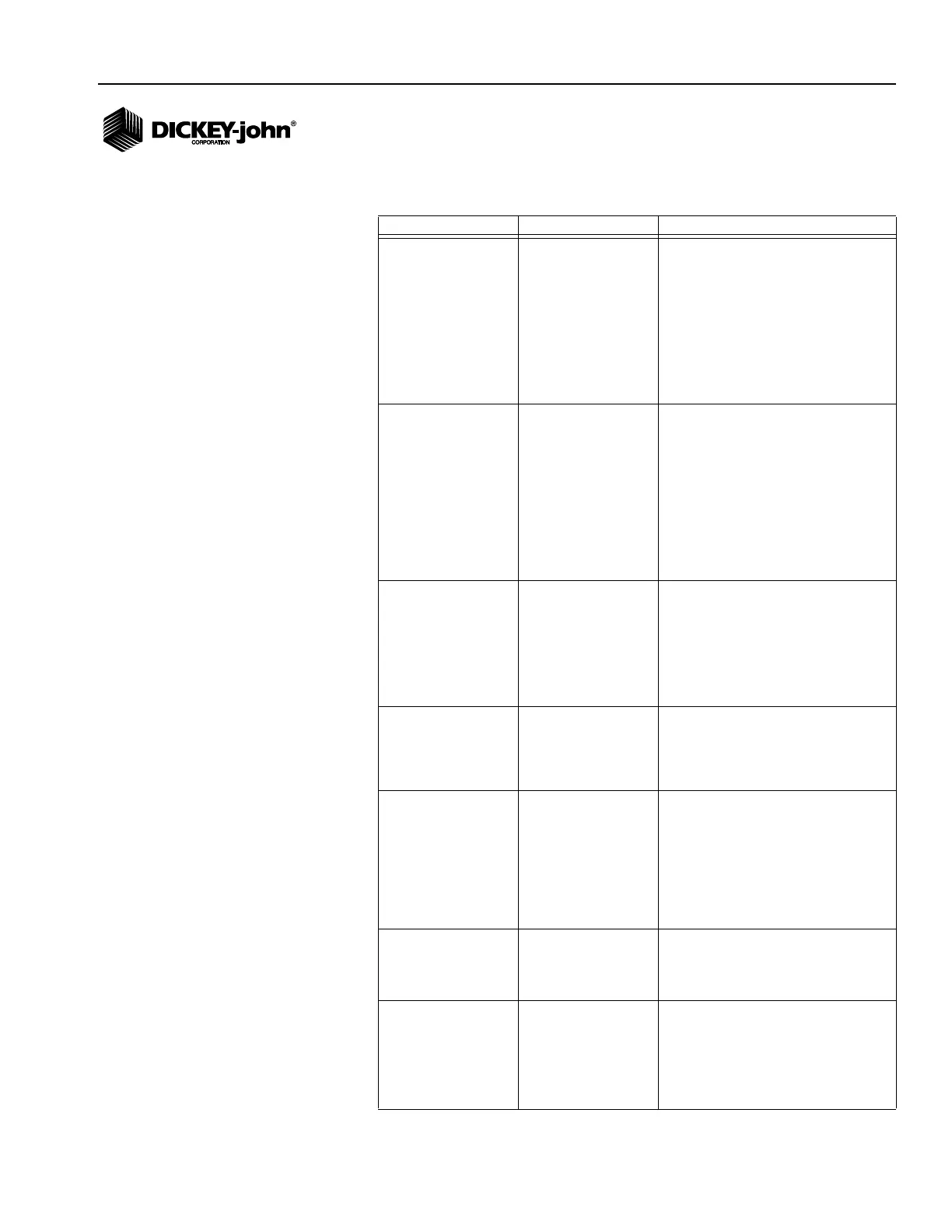

Issue Probable Cause Corrective Action

Monitor will not power on.

1. Blown console fuse

2. Poor battery connection

3. Low battery voltage

4. Defective console

1. Check fuse (located near battery connection).

If needed, replace with 5.0 A fuse maximum. If

fuse blows again, check all harnesses for

pinches or breaks that may cause power short

to ground.

2. Ensure connections are clean and tight.

Inspect harness for damage.

3. Console voltage must be at least 10 V. If low,

recharge or replace battery.

4. Contact your dealer, DICKEY-john USA

(1-800-637-3302), or DICKEY-john Europe

(011-33-141-192189).

Row failure or hi/low alarm

activates when row is

planting properly.

1. Seed sensor coated with

dirt

2. Faulty sensor or harness

3. Defective console.

1. Clean sensor using a dry bottle brush.

2. Drop seed down the seed tube or place a dry

bottle brush down the seed tube to trigger

sensor. Observe if troubleshooting sensor LED

mounted to the tube blinks. If sensor does not

blink, replace the sensor. If the sensor LED

blinks, check harness for damage or pinched

wires. If the sensor does not have an LED, swap

harness connection with adjacent sensor to

determine if sensor is damaged.

3.Contact your dealer, DICKEY-john USA

(1-800-637-3302), or DICKEY-john Europe

(011-33-141-192189).

Hopper alarm does not

sound when the hopper is

empty.

1. Hopper sensor coated

with dirt

2. Faulty sensor or harness

shorted to ground

3. Defective console

1. Clean sensor using a dry bottle brush.

2. Swap harness connection with another

sensor to determine if sensor or harness is

damaged. Use service screen if another sensor

is not available. Replace sensor or repair

harness.

3. Contact your dealer, DICKEY-john USA

(1-800-637-3302), or DICKEY-john Europe

(011-33-141-192189).

Hopper alarm sounds when

hopper is full.

1. Faulty sensor or harness

open

2. Defective console

1. Swap harness connection with another

sensor to determine if sensor or harness is

damaged. Replace sensor or repair harness.

3. Contact your dealer, DICKEY-john USA

(1-800-637-3302), or DICKEY-john Europe

(011-33-141-192189).

Ground speed alarm

sounds with forward

movement.

1. Ground speed sensor

failure

2. Console failure

3. Ground Speed constant

is set to 0.

1. No ground speed sensor is detected, or

planting is detected on atleast one row with no

ground speed. Replace faulty ground speed

sensor.

2. Contact your dealer, DICKEY-john USA

(1-800-637-3302), or DICKEY-john Europe

(011-33-141-192189).

3. Run a ground speed calibration and enter a

constant at the Ground Speed Configuration

screen.

Ground speed high alarm

sounds.

1. Ground speed alarm set

too low.

2. Incorrect ground speed

constant.

1. Set ground speed alarm limit higher or to zero

to disable.

2. Ground speed sensor has not been

calibrated, radar sensor angle has changed, or

incorrect sensor constant is entered.

Self test alarm

1. Faulty sensor or harness.

2. Console failure

1. Trigger sensor and observe troubleshooting

LED. If sensor does not have LED, swap

harness connection with adjacent sensor to

determine if sensor or harness id damaged.

Replace sensor or harness.

3. Contact your dealer, DICKEY-john USA

(1-800-637-3302), or DICKEY-john Europe

(011-33-141-192189).

Loading...

Loading...