【6-22】

NGINE

Piston pin and pin bore

ID of Piston hole for Pin

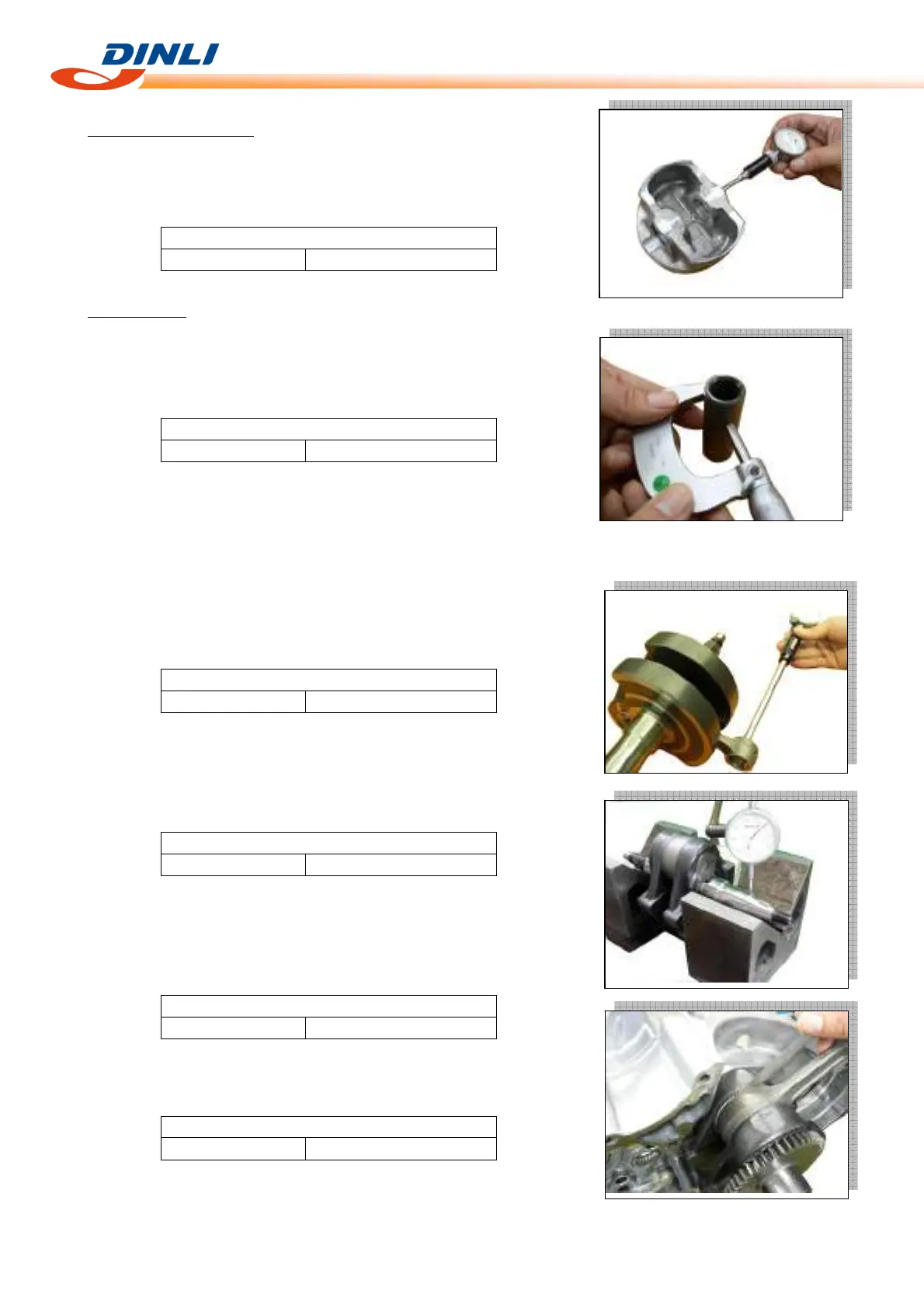

● Clean Piston hole for Pin.

● Measure ID in the up and down direction and the right angle

direction with dial caliper gauge.

ID of Piston hole for Pin

Service limit 23.030 mm

Piston Pin OD

● Check for ware and damage on the sliding surface.

● Measure OD at total 3 positions; both ends and middle position in

the X- and Y-direction.

Piston Pin OD

Service limit 22.980 mm

CONNECTING ROD

Small end ID

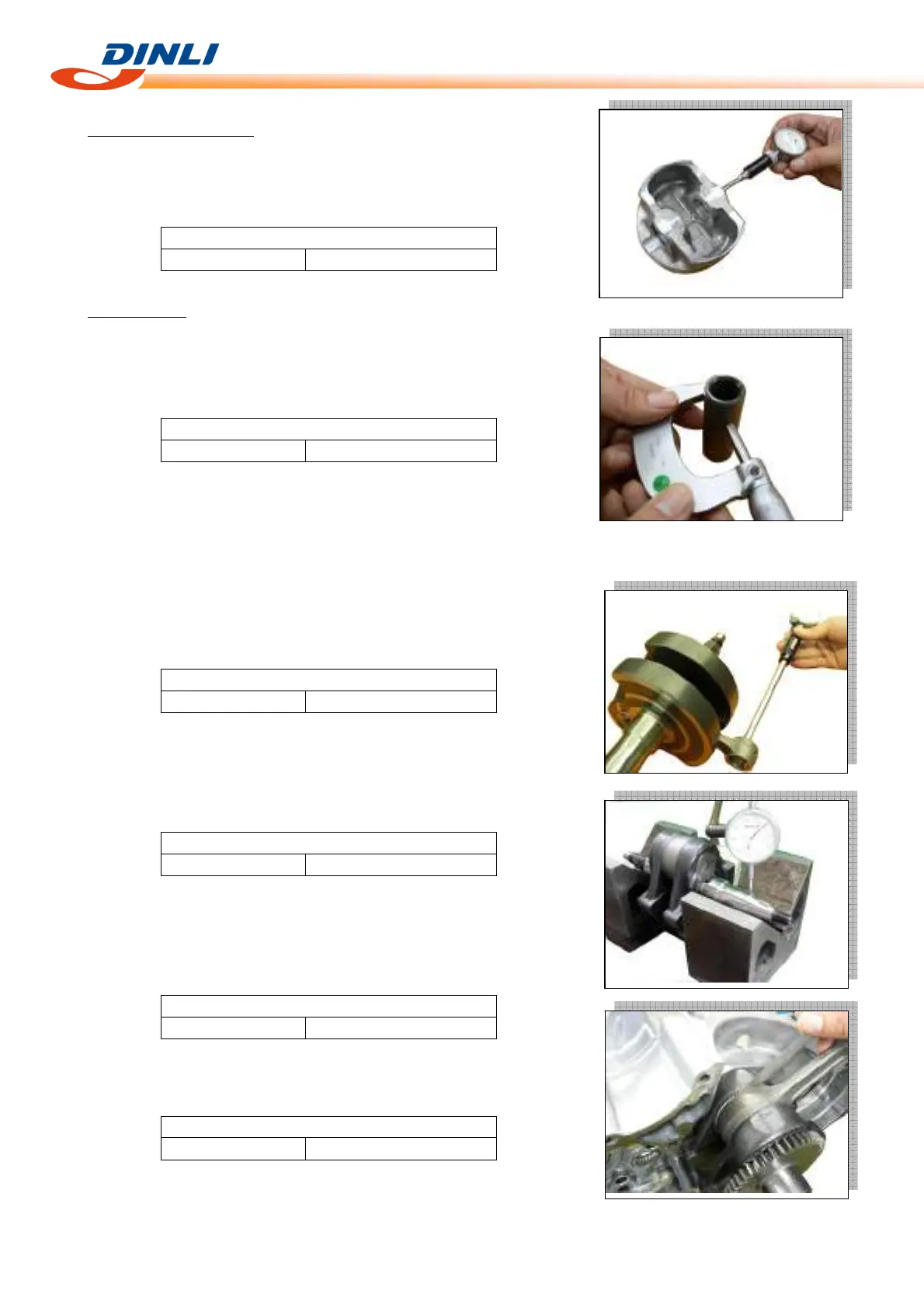

● Check for ware and damage on the sliding surface.

● Measure ID in the X- and Y-direction with caliper dial gauge.

Small end ID

Service limit 23.040 mm

Connecting rod deflection

● Wear of the big end of the rod can be estimated by checking the

movement of the small end of the rod.

● This method can also check the extent of wear on the rod’s big end.

Connecting Rod deflection

Service Limit 3.0 mm

Side-clearance at large end of Connecting Rod

● Measure the side-clearance at large end of Connecting Rod with

thickness gauge.

Side-clearance at large end

Service Limit 1.0 mm

Runout

● Set on the V-block and measure runout with dial gauge.

Crankshaft Runout

Service Limit 0.08 mm

Loading...

Loading...