routed into the combustion chamber based on intake

manifold vacuum.

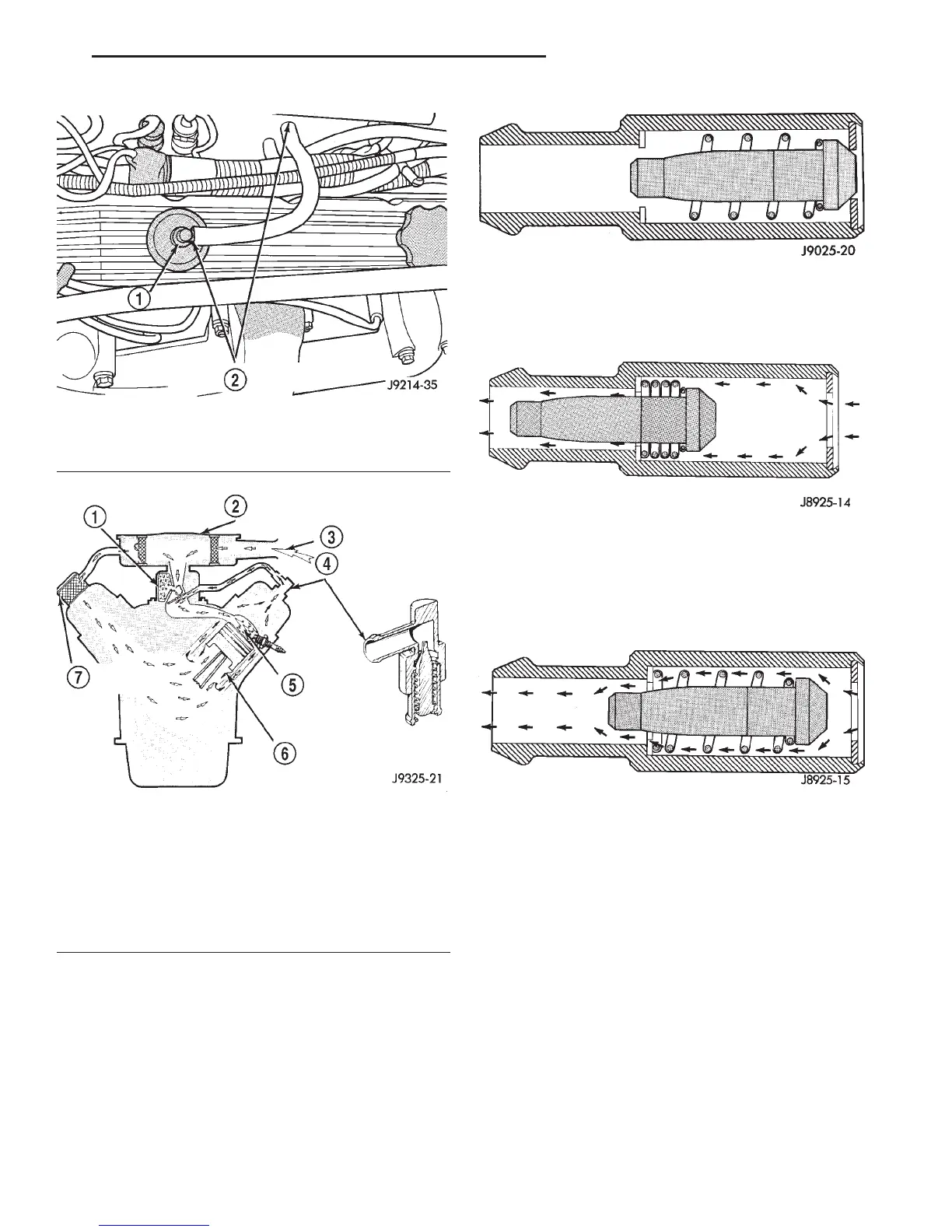

When the engine is not operating or during an

engine pop-back, the spring forces the plunger back

against the seat. This will prevent vapors from flow-

ing through the valve.

During periods of high manifold vacuum, such as

idle or cruising speeds, vacuum is sufficient to com-

pletely compress spring. It will then pull the plunger

to the top of the valve (Fig. 7). In this position there

is minimal vapor flow through the valve.

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve

(Fig. 8).

POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEM—4.7L ENGINE

DESCRIPTION

The 4.7L V-8 engine is equipped with a closed

crankcase ventilation system and a Positive Crank-

case Ventilation (PCV) valve.

This system consists of:

• a PCV valve mounted to the oil filler housing

(Fig. 9). The PCV valve is sealed to the oil filler

housing with an o-ring.

• the air cleaner housing

• two interconnected breathers threaded into the

rear of each cylinder head (Fig. 10).

• tubes and hose to connect the system compo-

nents.

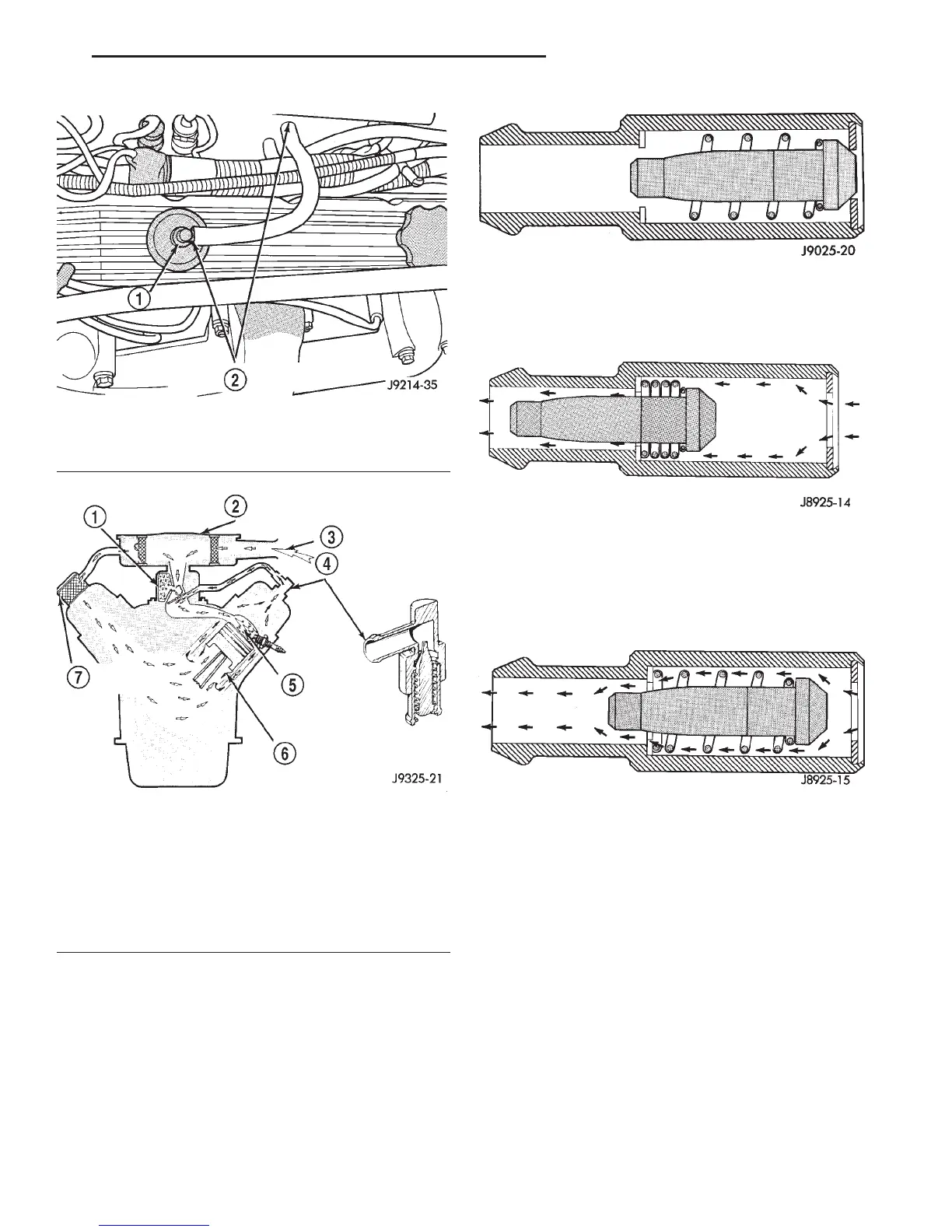

Fig. 4 PCV Valve/Hose—Typical

1 – PCV VALVE

2 – PCV VALVE HOSE CONNECTIONS

Fig. 5 Typical Closed Crankcase Ventilation System

1 – THROTTLE BODY

2 – AIR CLEANER

3 – AIR INTAKE

4 – PCV VALVE

5 – COMBUSTION CHAMBER

6 – BLOW-BY GASES

7 – CRANKCASE BREATHER/FILTER

Fig. 6 Engine Off or Engine Pop-Back—No Vapor

Flow

Fig. 7 High Intake Manifold Vacuum—Minimal Vapor

Flow

Fig. 8 Moderate Intake Manifold Vacuum—Maximum

Vapor Flow

DN EMISSION CONTROL SYSTEMS 25 - 27

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...