CAUTION: Radiator pressure testing tools are very

sensitive to small air leaks, which will not cause

cooling system problems. A pressure cap that does

not have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to tool. Turn tool upside

down and recheck pressure cap to confirm that cap

needs replacement.

COOLANT—LOW LEVEL AERATION

If the coolant level in the radiator drops below the

top of the radiator core tubes, air will enter the sys-

tem.

Low coolant level can cause the thermostat pellet

to be suspended in air instead of coolant. This will

cause the thermostat to open later, which in turn

causes higher coolant temperature. Air trapped in

cooling system also reduces the amount of coolant

circulating in the heater core. This may result in low

heat output.

COOLING SYSTEM—DEAERATION

As the engine operates, any air trapped in cooling

system gathers under the radiator cap. The next time

the engine is operated, thermal expansion of coolant

will push any trapped air past radiator cap into the

coolant reserve/overflow tank. Here it escapes to the

atmosphere into the tank. When the engine cools

down the coolant, it will be drawn from the reserve/

overflow tank into the radiator to replace any

removed air.

SERVICE PROCEDURES

COOLANT—ROUTINE LEVEL CHECK

NOTE: Do not remove radiator cap for routine cool-

ant level inspections. The coolant level can be

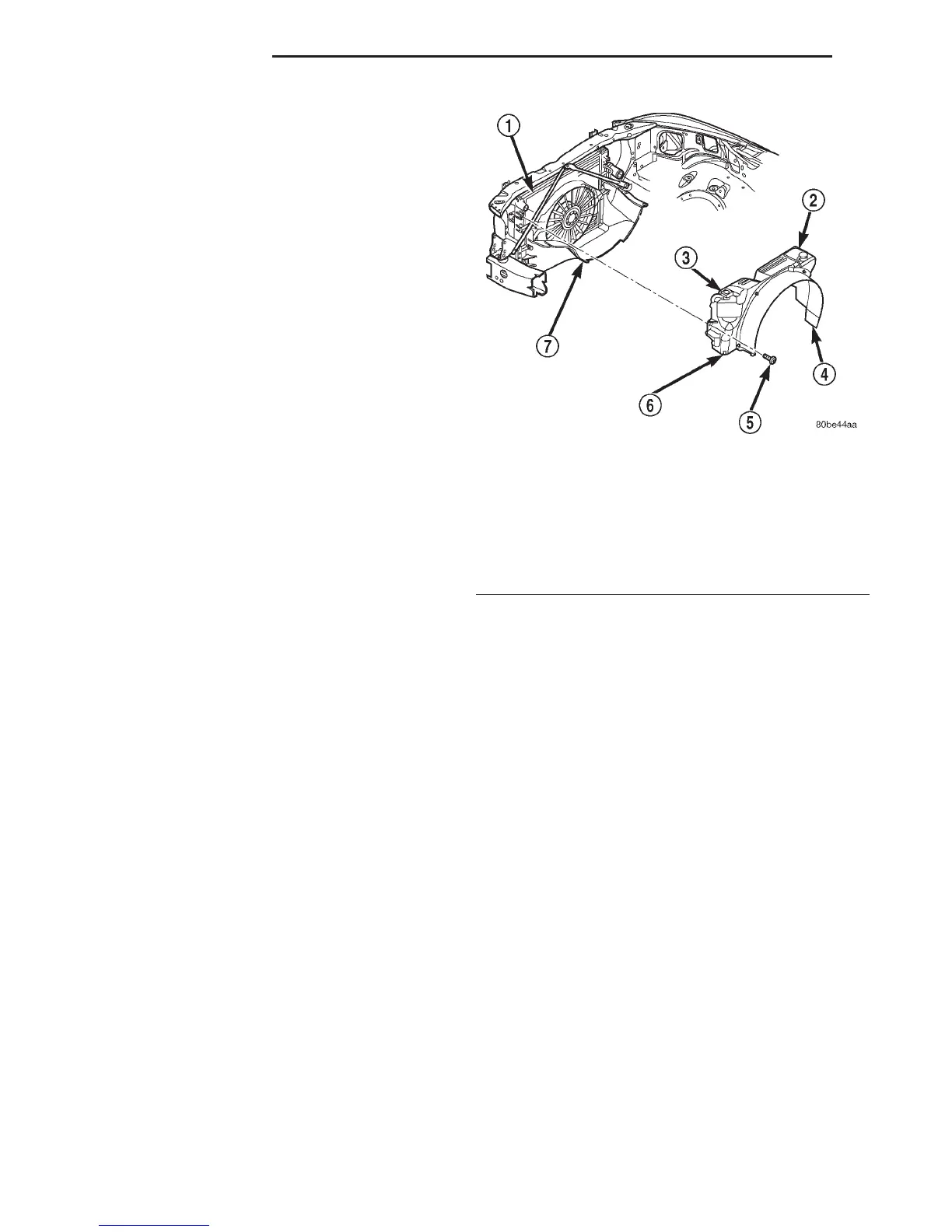

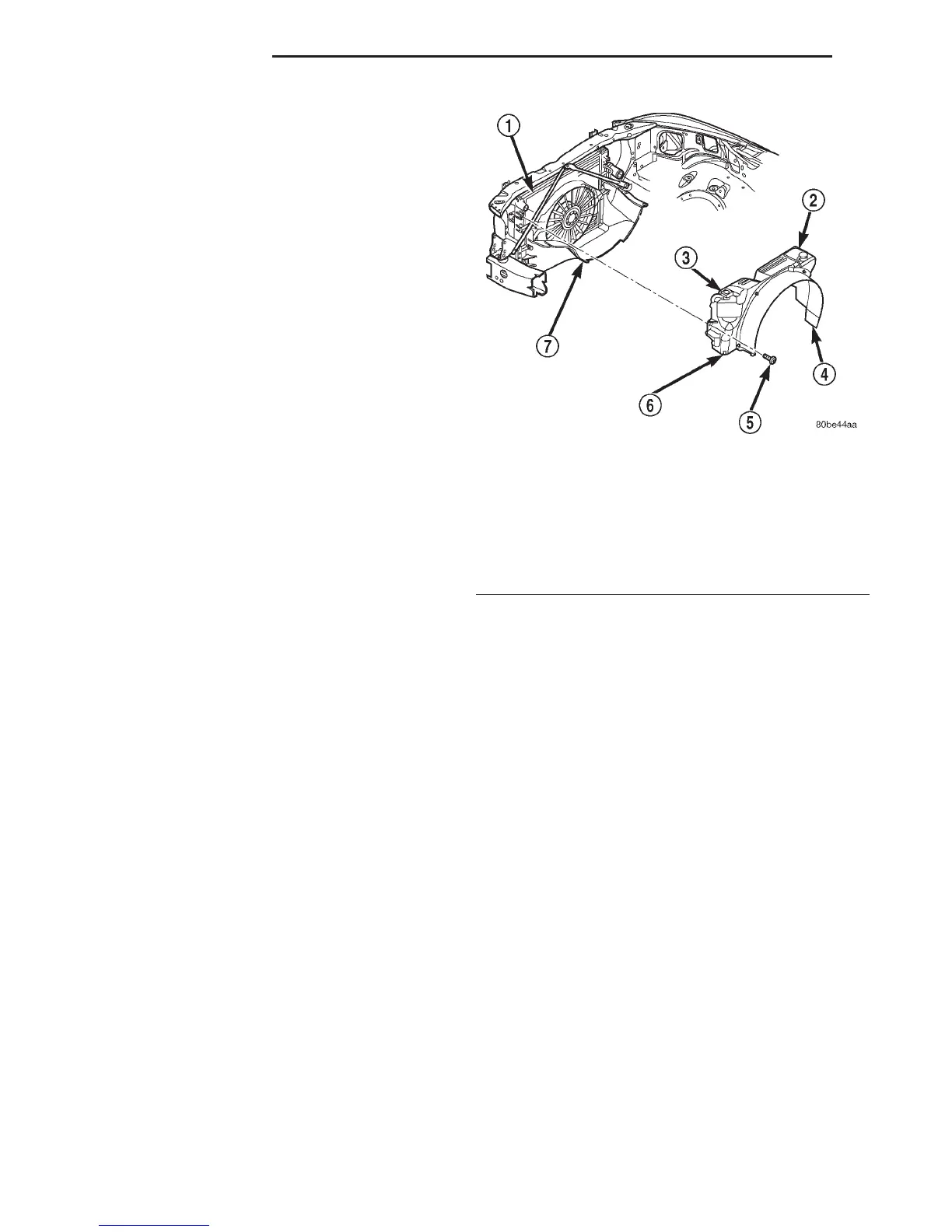

checked at coolant recovery bottle (Fig. 25).

The coolant reserve/overflow system provides a

quick method for determining coolant level without

removing radiator pressure cap. With engine not run-

ning, open the coolant recovery bottle cap and

remove coolant level indicator dipstick to observe

coolant level in coolant recovery bottle. The coolant

level should be between ADD and FULL marks. If

the coolant level is at or below the ADD mark, fill

the recovery bottle with a 50/50 mixture of antifreeze

and water ONE QUART AT A TIME. Repeat this pro-

cedure until the coolant level is at the FULL mark.

COOLANT SERVICE

For cooling system flush and fill maintenance

intervals, refer to Group 0, Lubrication and Mainte-

nance.

COOLANT

DESCRIPTION

ETHYLENE-GLYCOL MIXTURES

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

The required ethylene-glycol (antifreeze) and water

mixture depends upon the climate and vehicle oper-

ating conditions. The recommended mixture of 50/50

ethylene-glycol and water will provide protection

against freezing to -37 deg. C (-35 deg. F). The anti-

freeze concentration must always be a minimum of

44 percent, year-round in all climates. If percentage

is lower than 44 percent, engine parts may be

eroded by cavitation, and cooling system com-

ponents may be severely damaged by corrosion.

Maximum protection against freezing is provided

with a 68 percent antifreeze concentration, which

prevents freezing down to -67.7 deg. C (-90 deg. F). A

Fig. 25 Coolant Recovery Bottle Location

1 – RADIATOR

2 – WASHER FLUID RESERVOIR

3 – COOLANT OVERFLOW/RESERVOIR

4 – FAN SHROUD (UPPER)

5 – SCREW

6 – INTERLOCKING PINS

7 – FAN SHROUD (LOWER)

7 - 22 COOLING SYSTEM DN

DIAGNOSIS AND TESTING (Continued)

Loading...

Loading...