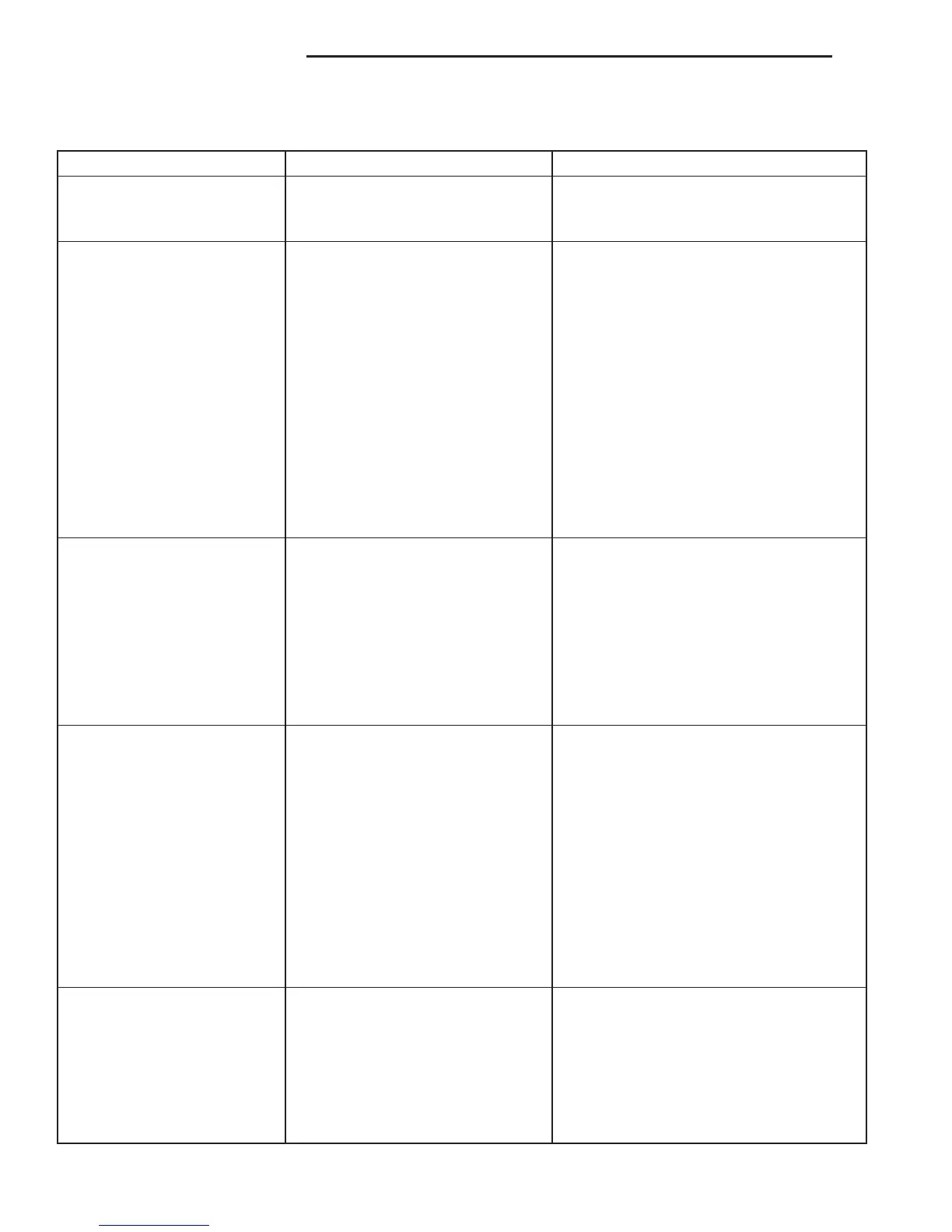

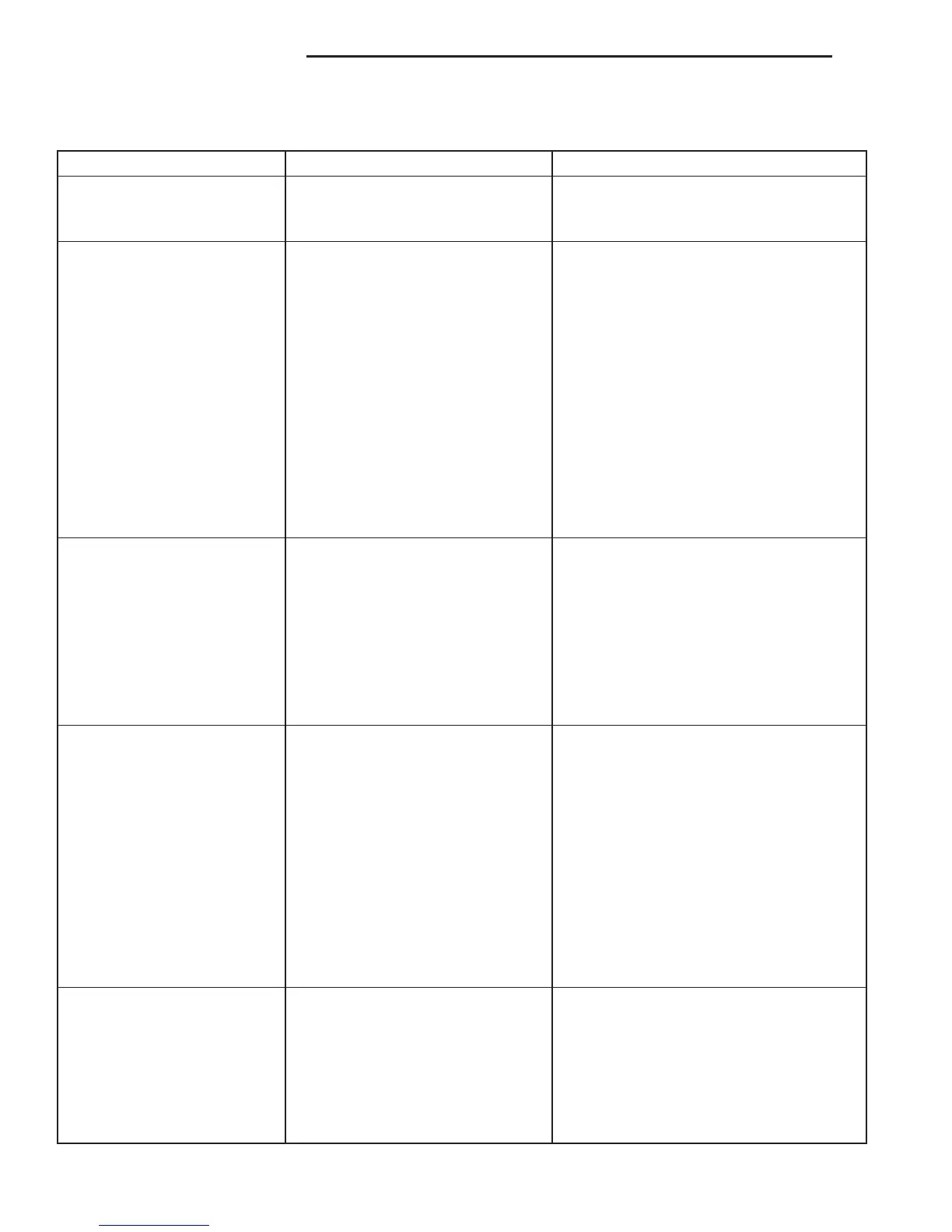

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment. Correct as

necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

3. End-play in pinion bearings. 3. Refer to pinion pre-load information and

correct as necessary.

4. Excessive gear backlash

between the ring gear and pinion.

4. Check adjustment of the ring gear and

pinion backlash. Correct as necessary.

5. Improper adjustment of pinion

gear bearings.

5. Adjust the pinion bearings pre-load.

6. Loose pinion companion flange

nut.

6. Tighten the pinion companion flange

nut.

7. Scuffed gear tooth contact

surfaces.

7. Inspect and replace as necessary.

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid or

correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect and

repair clutch as necessary.

Differential Cracked 1. Improper adjustment of the

differential bearings.

1. Replace case and inspect gears and

bearings for further damage. Set

differential bearing pre-load properly.

2. Excessive ring gear backlash. 2. Replace case and inspect gears and

bearings for further damage. Set ring gear

backlash properly.

3. Vehicle overloaded. 3. Replace case and inspect gears and

bearings for further damage. Avoid

excessive vehicle weight.

4. Erratic clutch operation. 4. Replace case and inspect gears and

bearings for further damage. Avoid erratic

use of clutch.

Differential Gears Scored 1. Insufficient lubrication. 1. Replace scored gears. Fill differential

with the correct fluid type and quantity.

2. Improper grade of lubricant. 2. Replace scored gears. Fill differential

with the correct fluid type and quantity.

3. Excessive spinning of one

wheel/tire.

3. Replace scored gears. Inspect all

gears, pinion bores, and shaft for damage.

Service as necessary.

3 - 66 8 1/4 AND 9 1/4 AXLE DN

DIAGNOSIS AND TESTING (Continued)

Loading...

Loading...