PROPELLER SHAFT JOINTS

DESCRIPTION

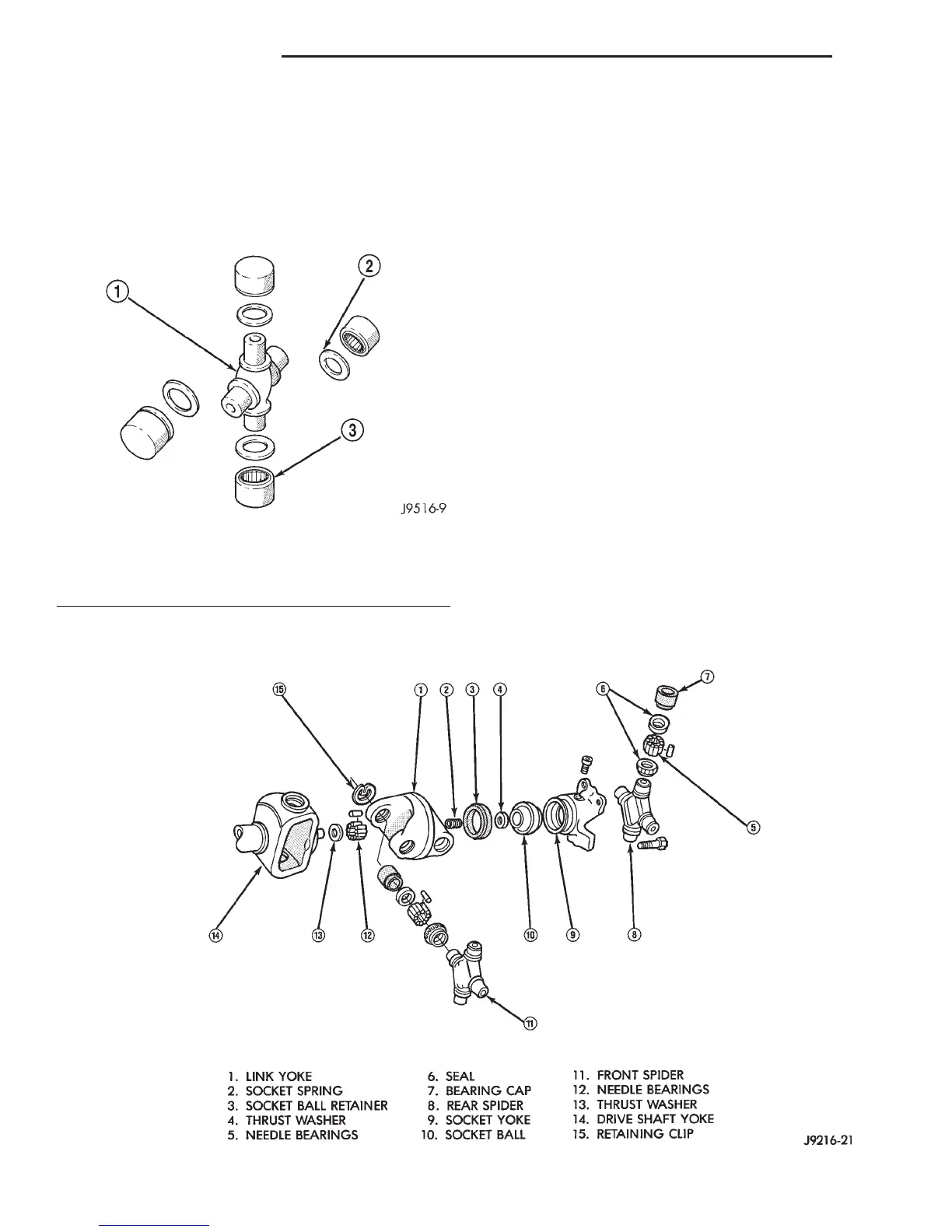

Two different types of propeller shaft joints are

used in AN vehicles (Fig. 5) and (Fig. 6). None of the

joints are serviceable. If worn or damaged, they must

be replaced as a complete assembly.

LUBRICATION

The factory installed universal joints are lubricated

for the life of the vehicle and do not need lubrication.

All universal joints should be inspected for leakage

and damage each time the vehicle is serviced. If seal

leakage or damage exists, the universal joint should

be replaced.

PROPELLER SHAFT JOINT ANGLE

DESCRIPTION

When two shafts come together at a common joint,

the bend that is formed is called the operating angle.

The larger the angle, the larger the amount of angu-

lar acceleration and deceleration of the joint. This

speeding up and slowing down of the joint must be

cancelled to produce a smooth power flow.

OPERATION

This cancellation is done through the phasing of a

propeller shaft and ensuring that the proper propel-

ler shaft joint working angles are maintained.

A propeller shaft is properly phased when the yoke

ends are in the same plane, or in line. A twisted

shaft will make the yokes out of phase and cause a

noticeable vibration.

When taking propeller shaft joint angle measure-

ments, or checking the phasing, of two piece shafts,

consider each shaft separately.

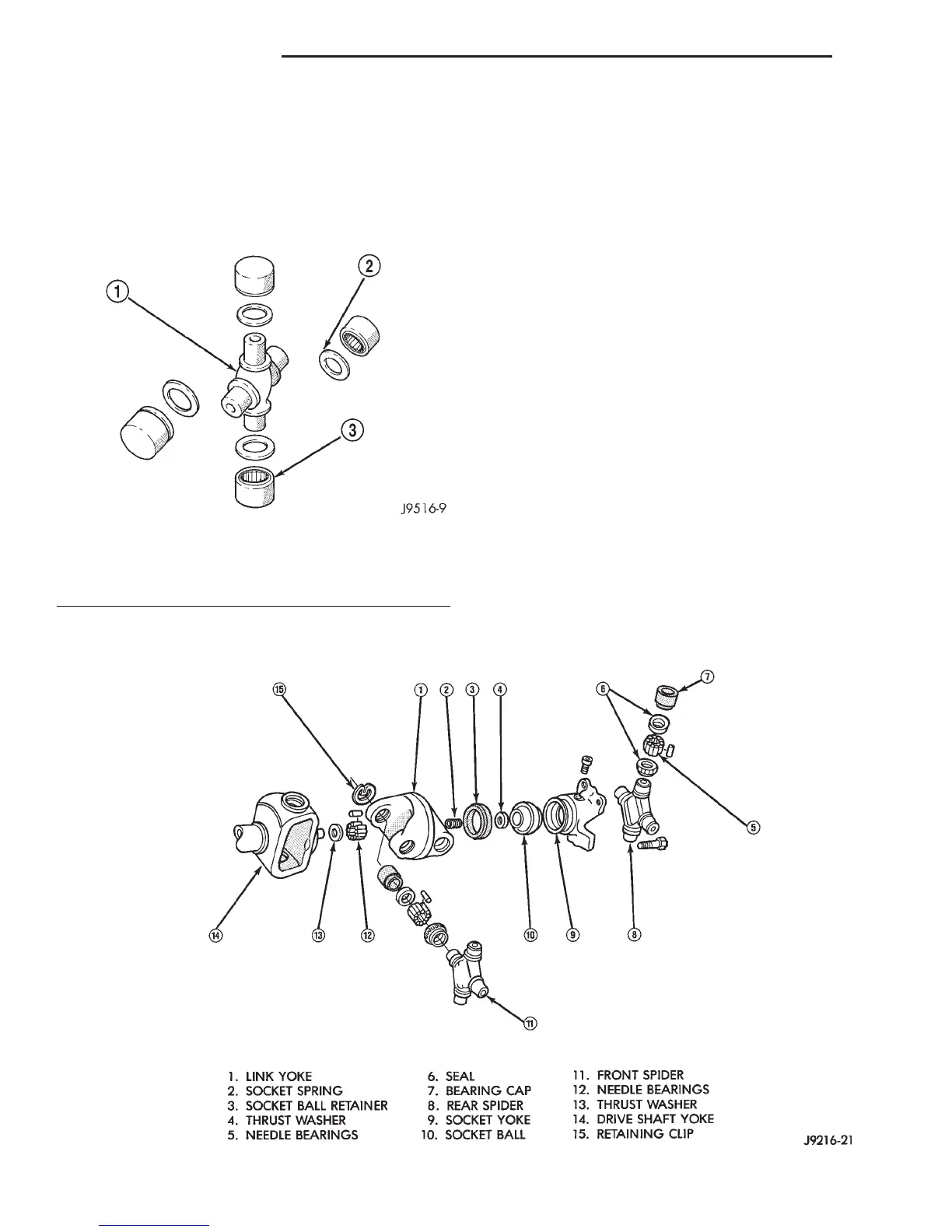

Fig. 6 Double Cardan U-Joint

Fig. 5 Single Cardan U-Joint

1 – CROSS

2 – SEAL

3 – CAP AND NEEDLE BEARINGS

3 - 4 PROPELLER SHAFTS DN

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...