CAUTION: If axle is submerged in water, lubricant

must be replaced immediately to avoid possible

premature axle failure.

STANDARD DIFFERENTIAL

DESCRIPTION

The differential gear system divides the torque

between the axle shafts. It allows the axle shafts to

rotate at different speeds when turning corners.

Each differential side gear is splined to an axle

shaft. The pinion gears are mounted on a pinion

mate shaft and are free to rotate on the shaft. The

pinion gear is fitted in a bore in the differential case

and is positioned at a right angle to the axle shafts.

OPERATION

In operation, power flow occurs as follows:

• The pinion gear rotates the ring gear

• The ring gear (bolted to the differential case)

rotates the case

• The differential pinion gears (mounted on the

pinion mate shaft in the case) rotate the side gears

• The side gears (splined to the axle shafts) rotate

the shafts

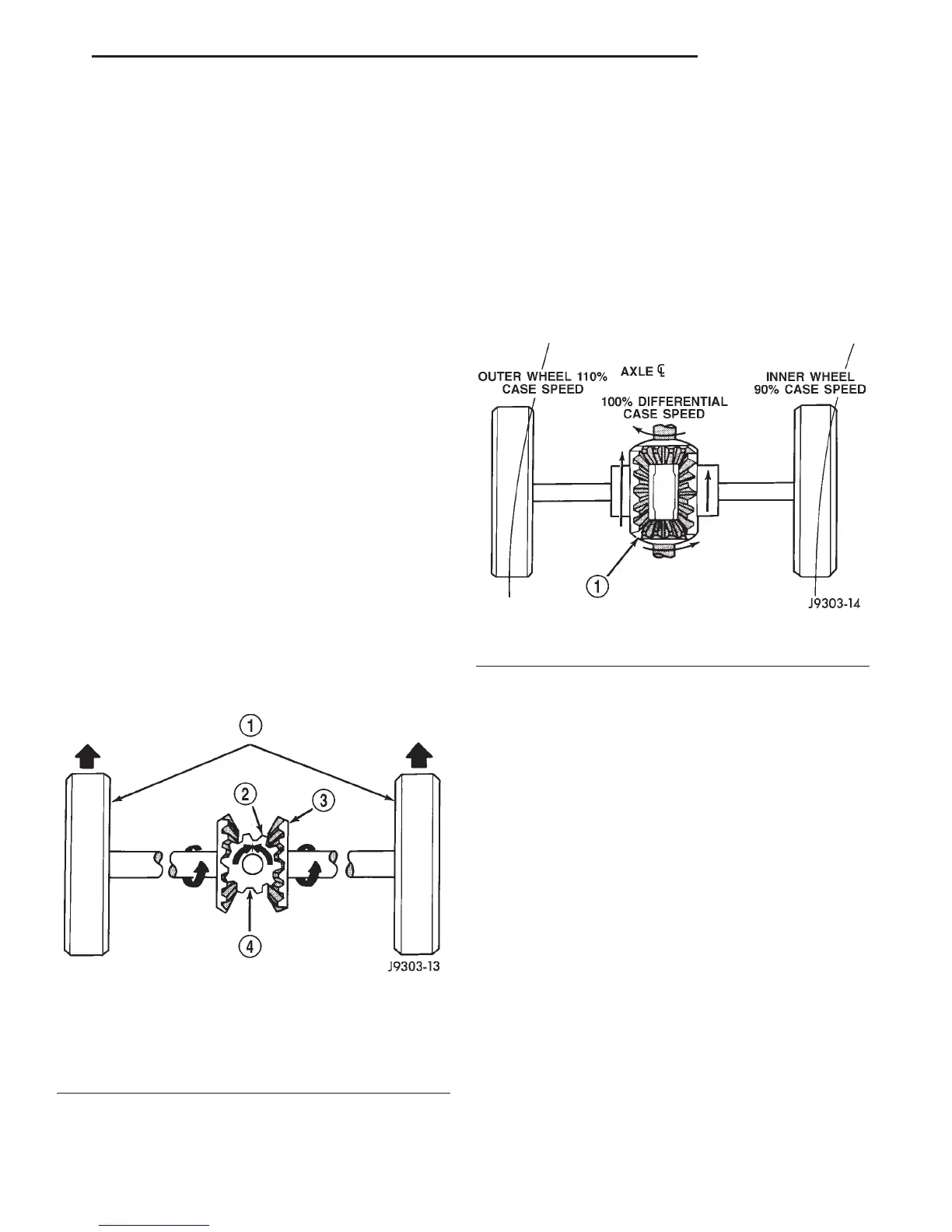

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig. 1).

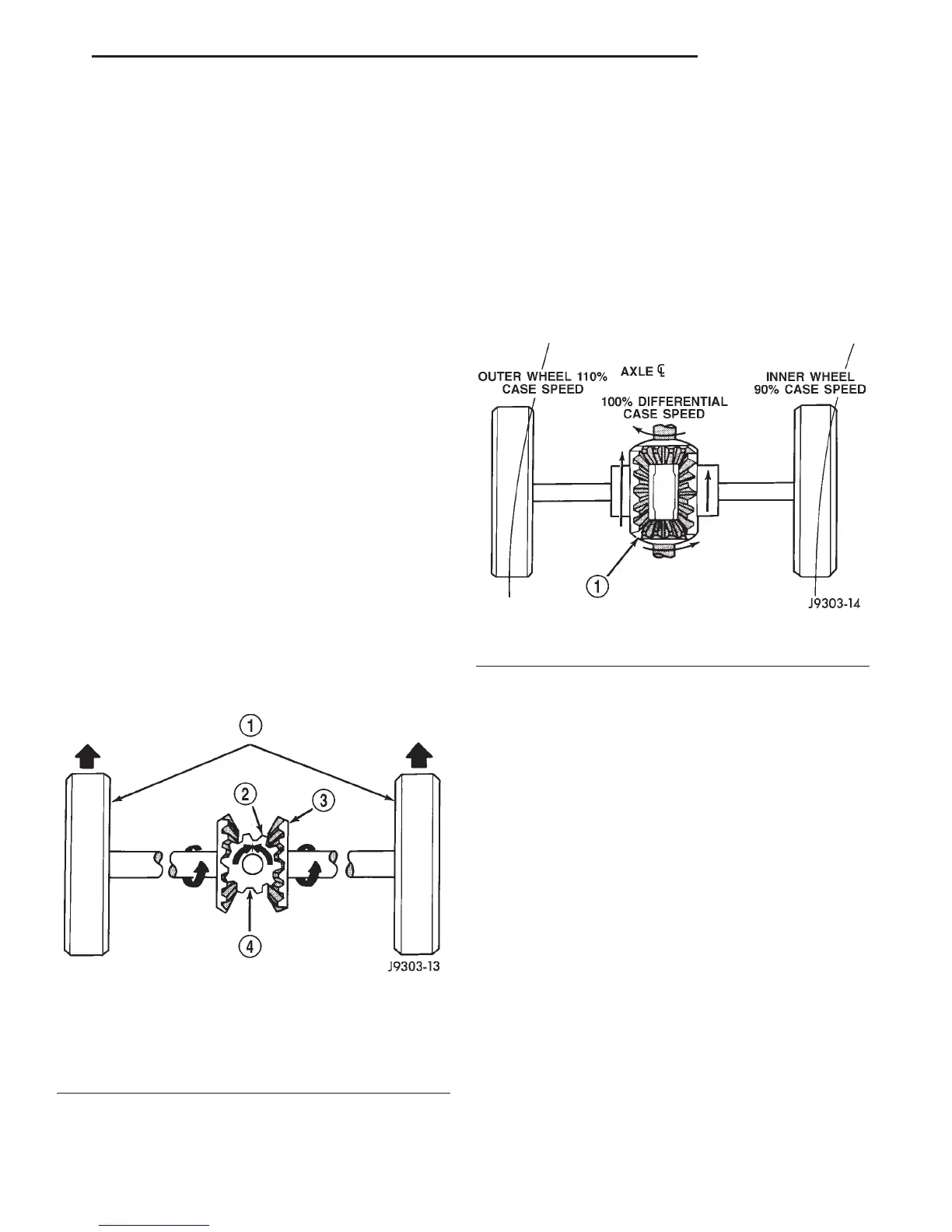

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. The difference must be compensated

for to prevent the tires from scuffing and skidding

through turns. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

2). In this instance, the input torque applied to the

pinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Axle bearing problem conditions are usually caused

by:

• Insufficient or incorrect lubricant.

• Foreign matter/water contamination.

• Incorrect bearing preload torque adjustment.

• Incorrect backlash.

Axle gear problem conditions are usually the result

of:

• Insufficient lubrication.

• Incorrect or contaminated lubricant.

• Overloading (excessive engine torque) or exceed-

ing vehicle weight capacity.

• Incorrect clearance or backlash adjustment.

Axle component breakage is most often the result

of:

• Severe overloading.

• Insufficient lubricant.

• Incorrect lubricant.

• Improperly tightened components.

• Differential housing bores not square to each

other.

Fig. 1 Differential Operation—Straight Ahead Driving

1 – IN STRAIGHT AHEAD DRIVING EACH WHEEL ROTATES AT

100% OF CASE SPEED

2 – PINION GEAR

3 – SIDE GEAR

4 – PINION GEARS ROTATE WITH CASE

Fig. 2 Differential Operation—On Turns

1 – PINION GEARS ROTATE ON PINION SHAFT

DN C205F AXLE 3 - 31

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...