FINAL ASSEMBLY

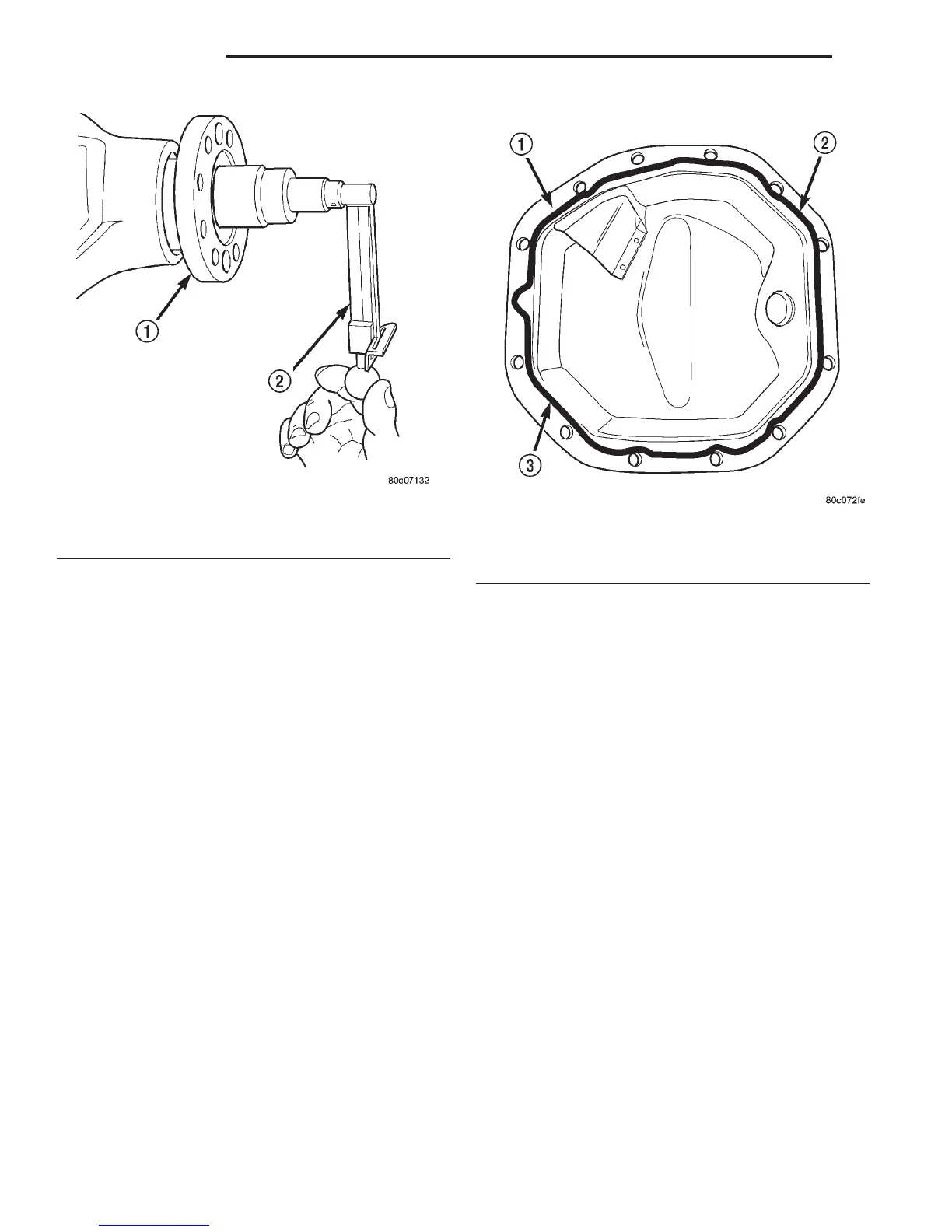

(1) Scrape the residual sealant from the housing

and cover mating surfaces. Clean the mating surfaces

with mineral spirits. Apply a bead of Mopart Silicone

Rubber Sealant, or equivalent, on the housing cover

(Fig. 32).

Install the housing cover within 5 minutes

after applying the sealant.

(2) Install the cover on the differential with the

attaching bolts. Install the identification tag. Tighten

the cover bolts to 23 N·m (17 ft. lbs.) torque.

CAUTION: Overfilling the differential can result in

lubricant foaming and overheating.

(3) Refill the differential housing with gear lubri-

cant. Refer to the Lubricant Specifications section of

this group for the gear lubricant requirements.

(4) Install the fill hole plug.

DISASSEMBLY AND ASSEMBLY

STANDARD DIFFERENTIAL

DISASSEMBLY

(1) Remove ring gear.

(2) Remove roll-pin holding mate shaft in housing.

(3) Remove pinion gear mate shaft (Fig. 33).

(4) Rotate the differential side gears and remove

the pinion mate gears and thrust washers (Fig. 34).

(5) Remove the differential side gears and thrust

washers.

ASSEMBLY

(1) Install the differential side gears and thrust

washers.

(2) Install the pinion mate gears and thrust wash-

ers.

(3) Install the pinion gear mate shaft.

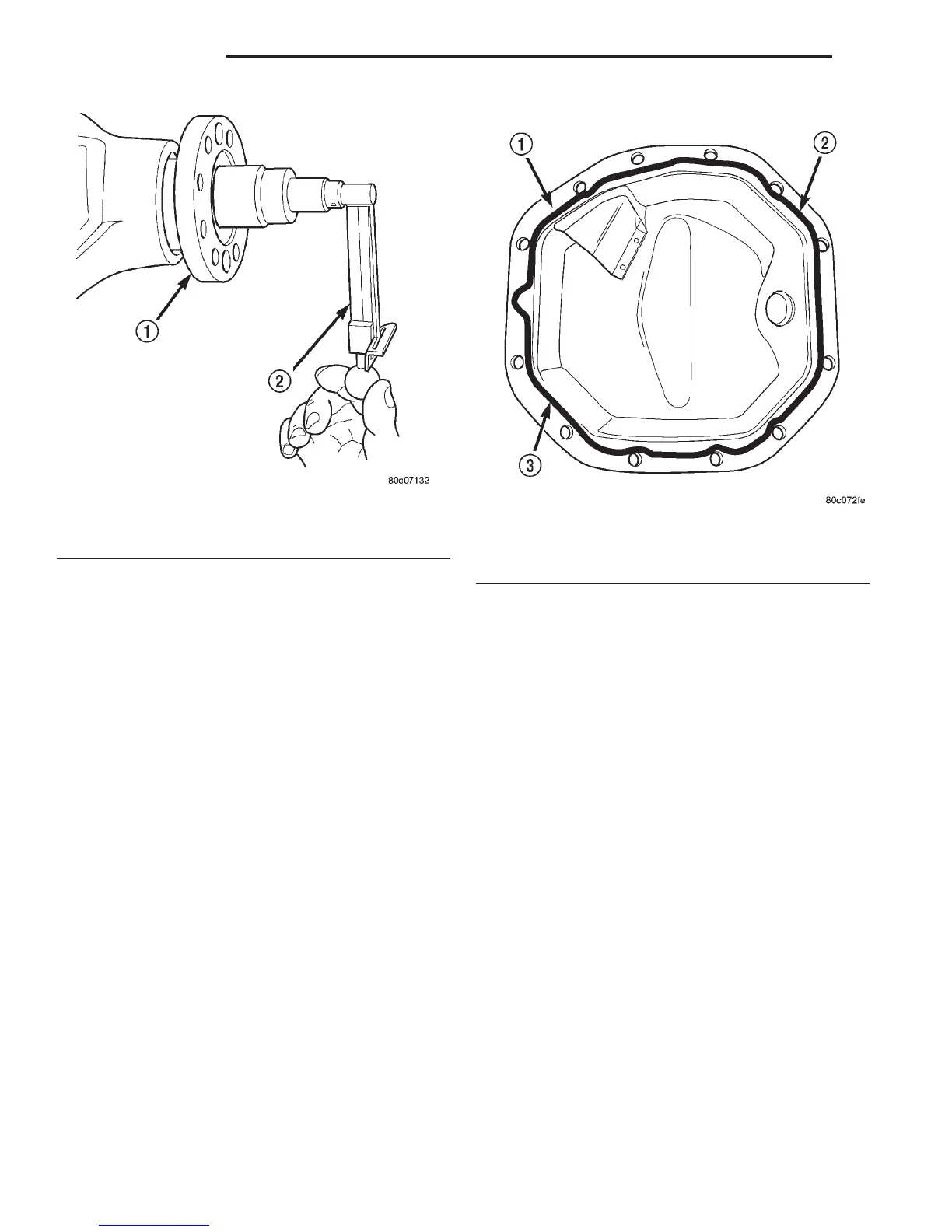

Fig. 31 Check Pinion Rotating Torque

1 – COMPANION FLANGE

2 – INCH POUND TORQUE WRENCH

Fig. 32 Typical Housing Cover With Sealant

1 – SEALING SURFACE

2 – CONTOUR OF BEAD

3 – BEAD THICKNESS 5.0mm (3/16”)

3 - 46 C205F AXLE DN

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...