9.2.8. Piston

1) Visual check

Visually check the pistons for cracks,

scuff or wear, paying particular attention

to the ring groove.

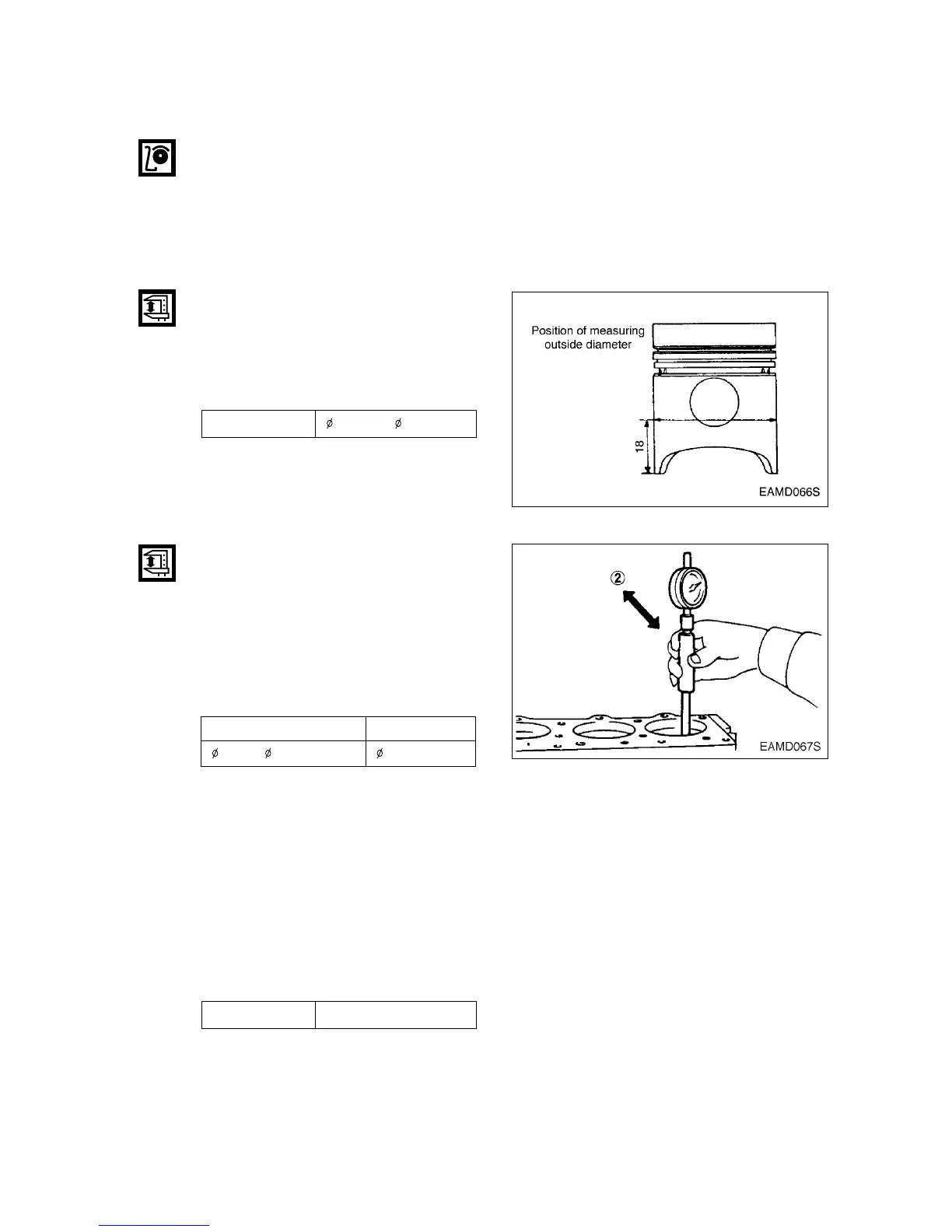

2) Clearance between the piston and

cylinder liner

•

With an outside micrometer, measure

the piston outside diameter at a point

18mm away from the lower end of pis-

ton skirt in a direction at a right angle to

the piston pin hole.

•

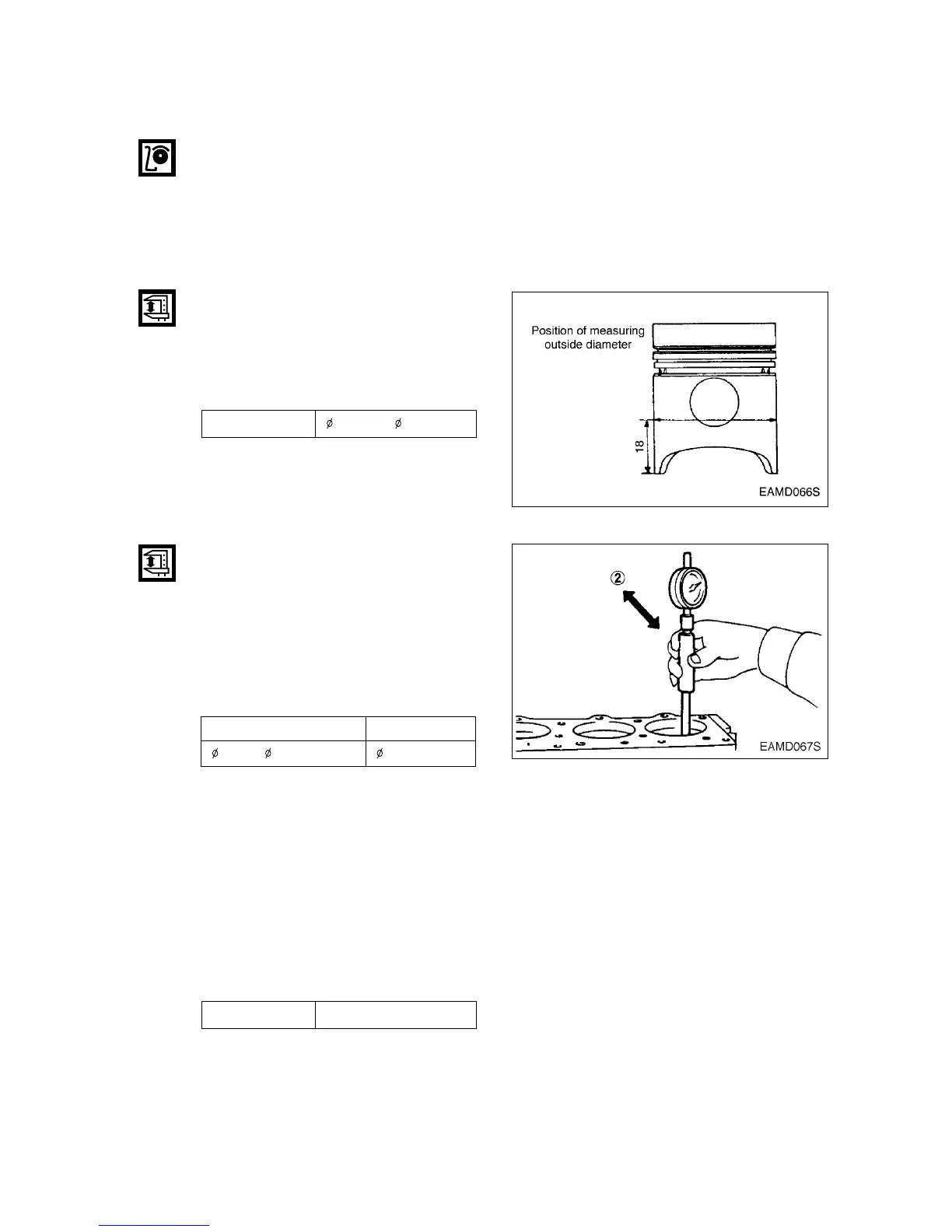

Using a cylinder bore gauge, measure

cylinder liner inside diameter at 3

points (cylinder top ring contacting

face, middle, and oil ring contacting

face on BDC) in a direction at an angle

of 45

. Take the mean value with the

largest and smallest values excepted.

•

The clearance is computed by sub-

tracting the piston outside diameter

from the cylinder liner inside diameter.

Replace either piston or cylinder liner,

whichever damaged more, if the clear-

ance is beyond the specified limit.

Clearance between piston and liner

- 87 -

Standard

122.433 ~ 127.863 mm

Standard 0.109 ~ 0.166 mm

Standard Limit

123 ~ 123.023 mm 123.223 mm

Loading...

Loading...