Page 62 • DRI-STEEM XT Series Electrode Steam Humidifier Installation, Operation, and Maintenance Manual

Troubleshooting (continued)

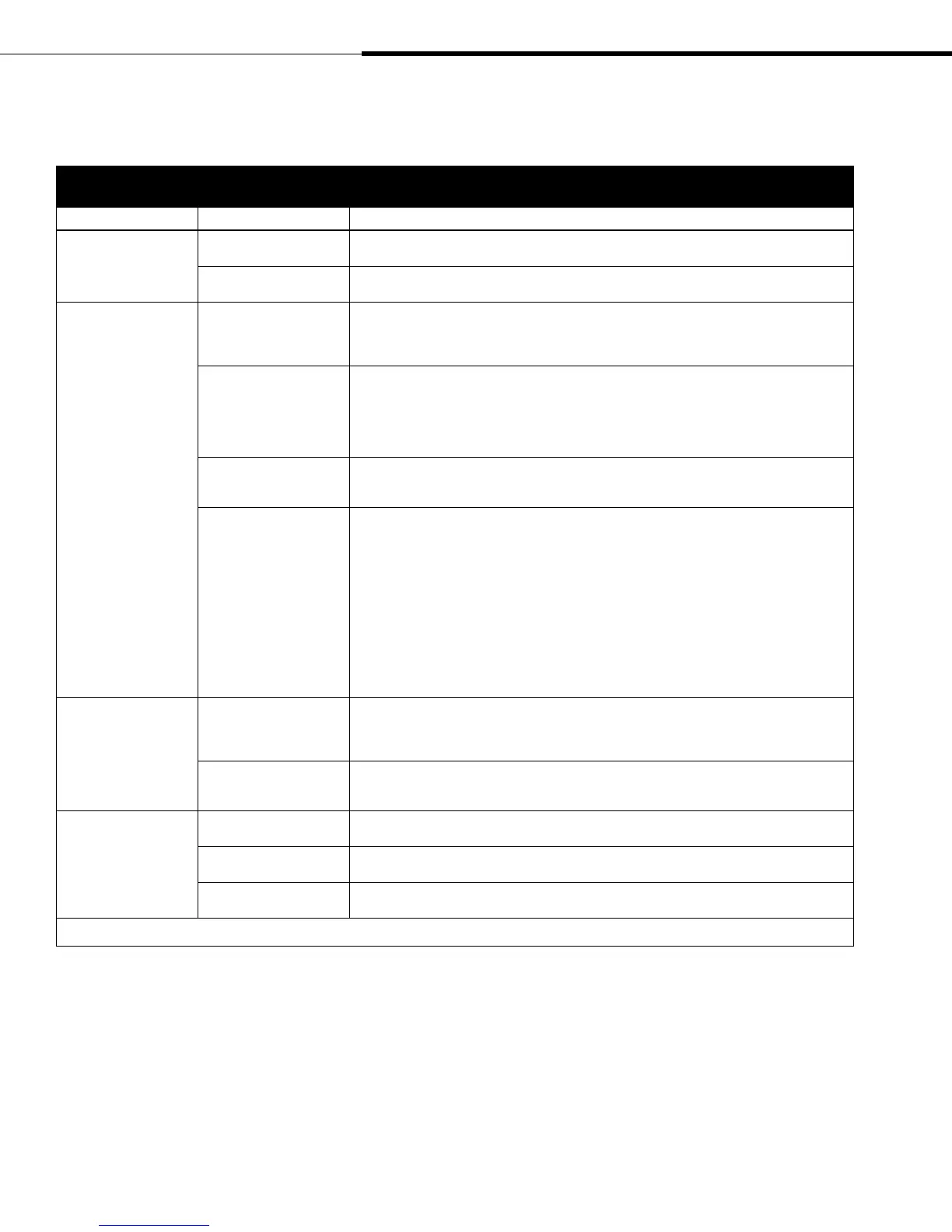

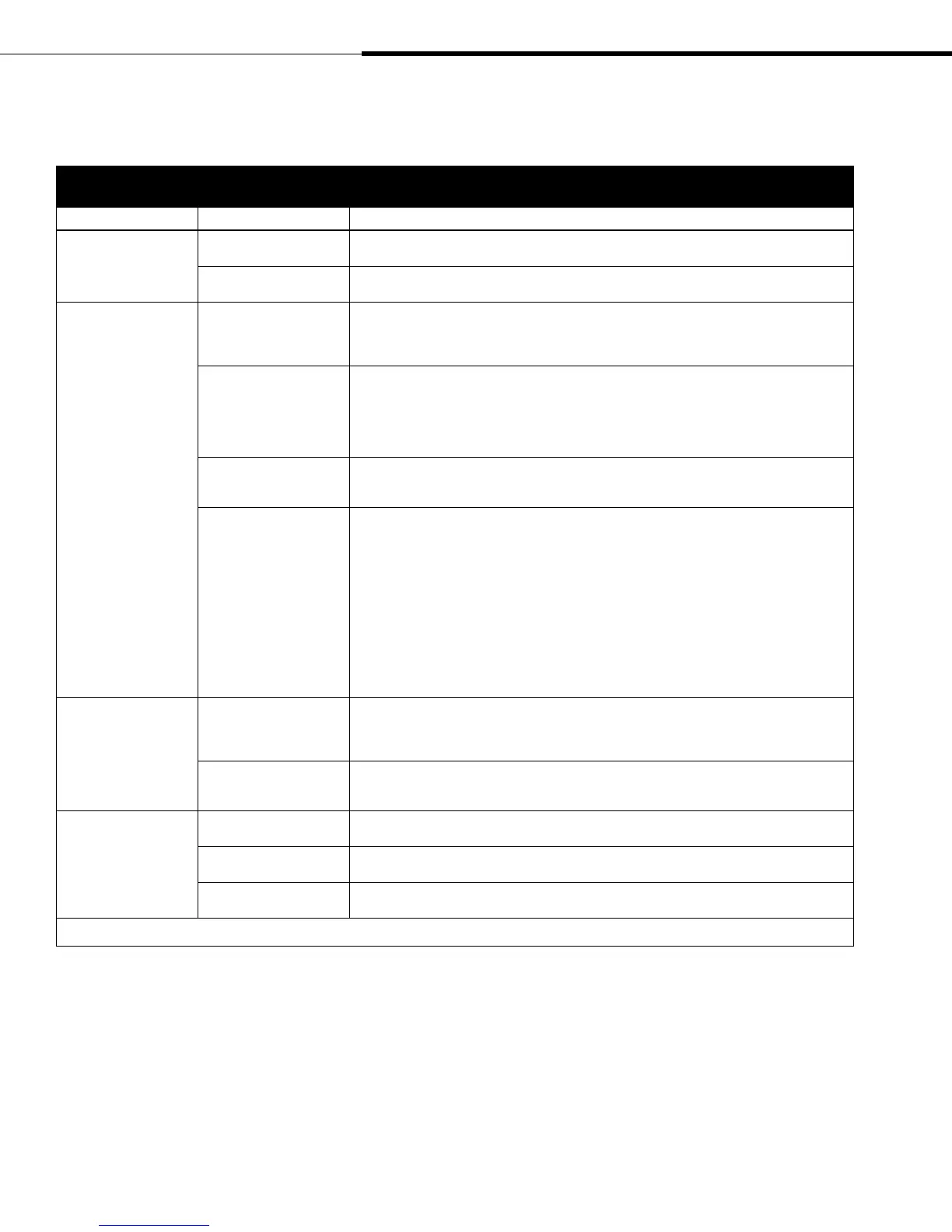

Table 62-1:

Problem/possible cause/action

Problem Possible cause Action

No readable information

on display

No power or incorrect

voltage to processor board

• Check main power supply.

• Reset control transformer circuit breaker if tripped.

Modular communication

cable is disconnected.

• Connect modular cable.

Humidifier does not

energize; steam cylinder

does not heat up

Non-existent supply voltage

to humidifier

• Check main line fuse.

• Check main line safety switch.

• Verify terminal block electrical connections.

• Verify contactor electrical connections.

Non-existent control voltage • Check for proper supply voltage per wiring diagram.

• Verify proper wiring of multi-tap transformer.

• Verify terminal block electrical connections.

• Check for control circuit voltage, 24 VAC. If voltage is not present, check transformer circuit breaker.

• Reset if needed by pressing On/Off switch on display panel.

• Check door interlock switch continuity.

H-H terminals are open. • Check if auxiliary limit controls are not allowing system to operate, e.g., high limit humidistat, airflow

proving switch, etc. Reset, replace, or calibrate as needed. Jumper H-H if auxiliary limit controls are

not used.

Transmitter or humidistat

faults:

• Open, shorted, or incorrect

wiring of transmitter or

humidistat

• Signal is incorrect, out of

range, or miswired.

• Ground loop

• Control signal exceeded

the range limits. Correct

signals are 4 to 20 mA, 0

to 135 ohms, or 0 to 10

VDC.

• Check DC supply voltage terminals of RH transmitter, VAV humidity transmitter, or humidistat:

– Terminal 13: 21 VDC; Terminal 23: GND

• If there is no output 4 to 20 mA, replace transmitter. Transmitter by others may not be compatible.

Consult DRI-STEEM.

• Isolation control board by others may not be compatible. Consult DRI-STEEM.

• Recalibrate if there is a calibration error: Normal range 4 to 20 mA = 0 to 100% RH;

12 mA = 50% RH

• Measure for normal 0 to 10 VDC or 4 to 20 mA control signal.

Reduced or no output

(even though water

level is correct)

Malfunctioning control

system

• Check if auxiliary limit controls are not allowing system to operate, e.g., high limit humidistat, airflow

proving switch, etc. Reset, replace, or calibrate as needed. Jumper H-H if auxiliary limit controls are

not used.

• Check fuse in power circuit. If open, replace fuse with equal fuse.

Steam cylinder

malfunctioning

• Verify that proper voltage is being applied to the steam cylinder.

• Check current through electrode wires.

• If power components are not functioning, replace.

Steam cylinder failure Improper wiring • Verify proper voltage applied to steam cylinder.

• Verify proper electrical connections.

Mineral buildup on steam

cylinder electrodes

• Inspect steam cylinder for severe mineral buildup on or around electrodes. If present, increase

cleaning frequency or replace steam cylinder.

Steam cylinder electrode

corrosion

• Inspect electrodes for surface corrosion or pitting. This is usually caused by a high chloride level in the

supply water. Test water and consult DRI-STEEM for advice.

More on the next page

▶

XT_IOM_Jan_2008.pdf 64 11/19/2009 10:13:40 AM

Loading...

Loading...