DRI-STEEM XT Series Electrode Steam Humidifier Installation, Operation, and Maintenance Manual • Page 63

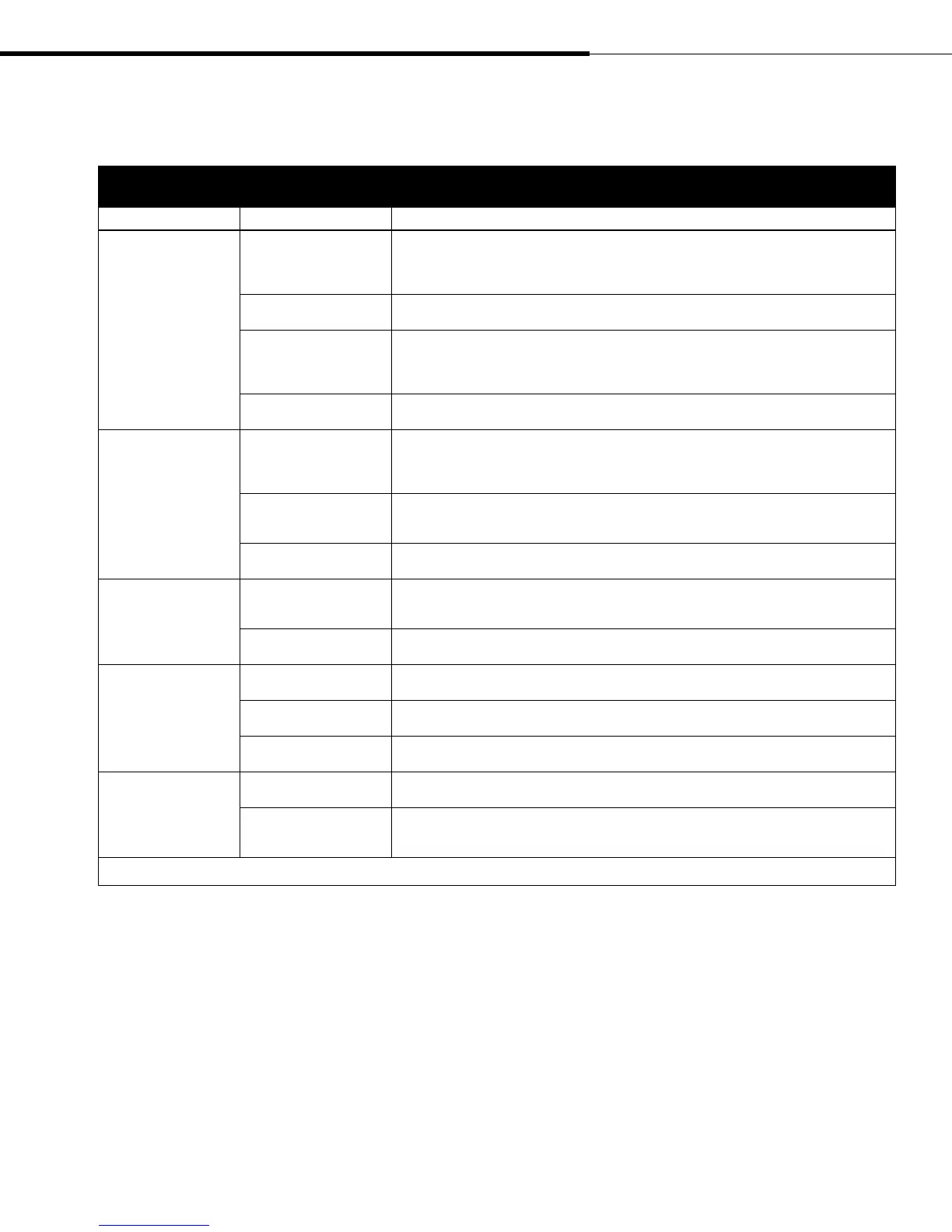

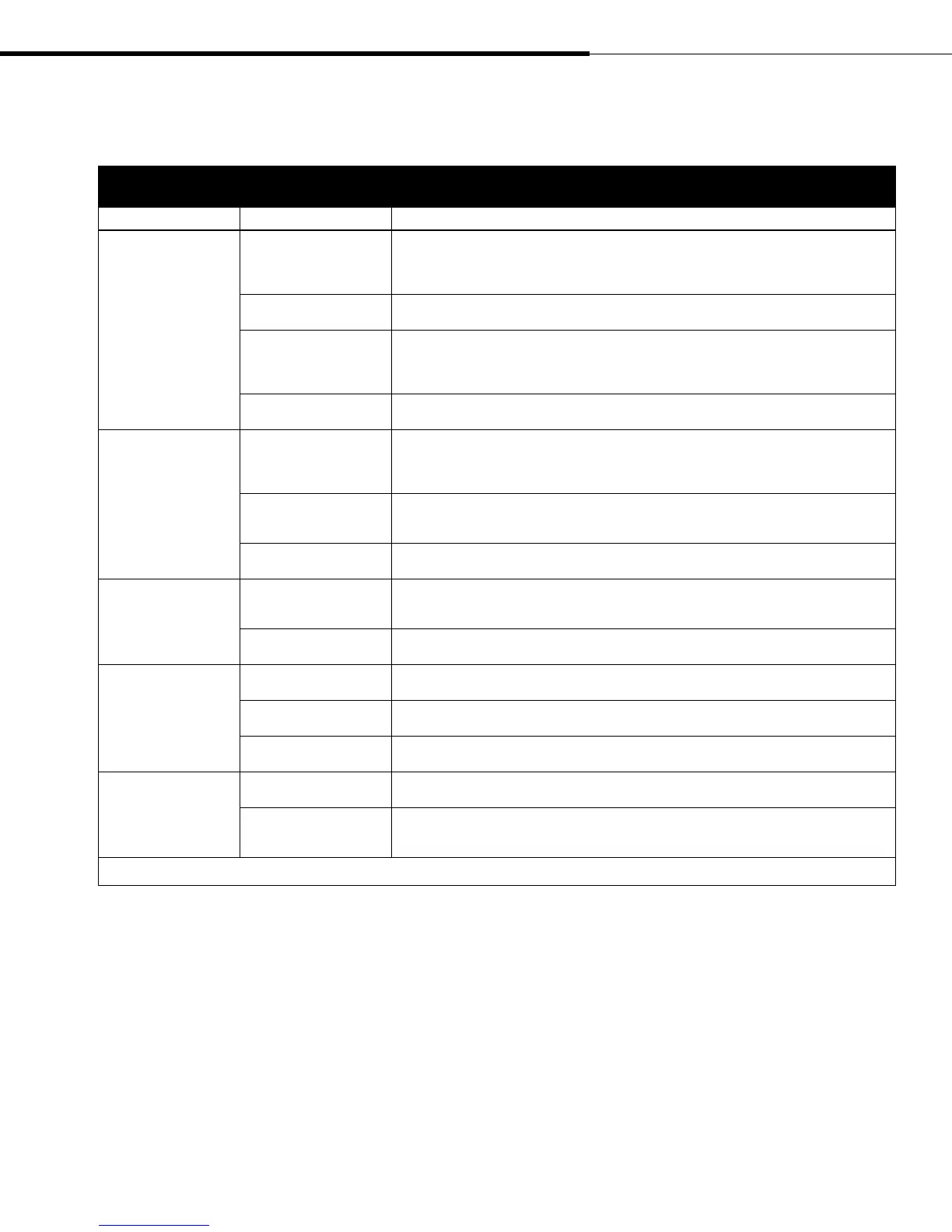

Table 63-1:

Problem/possible cause/action

Problem Possible cause Action

Unit does not fill with

water.

No water supply to fill valve • Verify that manual water supply valve is open and that pressure exists.

• Check if water supply line strainer is plugged. Clean strainer or replace.

• Verify fill valve electrical connections.

• Clean or replace fill valve strainer if plugged.

Unit control is not on • Press On/Off switch on display panel.

• Verify transformer electrical connections.

Malfunctioning fill valve • Cycle fill valve while in Service mode. If fill valve does not open:

– Verify fill valve electrical connections.

– Verify proper 24 VAC (terminals 2 and 5) to fill valve. If voltage is present and valve does

not open, replace valve.

Humidifier is in end-of-

season drain mode.

• Check for humidification demand signal at control board. See control wiring diagrams for terminal

check points.

Fill valve does not close. Malfunctioning level control

system

• Check that high water sensor electrical plug is fully engaged.

• Check water conductivity. Water conductivity must be at least 125 μS/cm

. Add sodium bicarbonate

through steam outlet on top of steam cylinder to increase. Start with ¼ tablet. Consult DRI-STEEM for

further advice.

Fill valve is stuck. • Check for control voltage across fill valve coil (terminals 2 and 5 on control terminal strip).

• Check if there is an obstruction that does not allow valve to seat properly. Clean or replace valve as

needed.

Drain valve is open. • Clean or replace drain valve if an obstruction in the valve does not allow complete closure.

• Replace broken or weak return spring on drain valve.

Fill valve cycles on and

off frequently (several

times per minute)

Malfunctioning level control

system

• Check water conductivity. Water conductivity must be at least 125 μS/cm

. Add sodium bicarbonate

through steam outlet on top of the steam cylinder to increase. Start with ¼ tablet.

Consult DRI-STEEM for further advice.

Drain valve not fully closed • If an obstruction does not allow drain valve to fully close, clean valve.

• Replace broken or weak return spring on drain valve.

Unit does not perform

autodrain sequence

No power to automatic drain

valve

• Verify drain valve electrical connections.

• Check if 24 VAC is present at the internal controller board terminals 3 and 6 for drain valve.

Drain fault, plugged drain

valve, or plugged drain pipe

• Check drain valve piping.

Defective automatic drain

valve

• If voltage is present at valve and it still does not open, replace valve.

Unit does not perform

end-of-season drain

Input signal always has a

demand

• Reduce demand signal.

Drain valve • Verify drain valve electrical connections.

• Verify drain valve is wired correctly to control board.

• Check 24 VAC across valve coil during test cycle (terminals 3 and 6 on control terminal strip).

More on the next page

▶

Troubleshooting (continued)

XT_IOM_Jan_2008.pdf 65 11/19/2009 10:13:40 AM

Loading...

Loading...