171

m Drum Section

chap.4

(3) Adjusting the Master Clump

¡For removal.

When the master clump parallelism is not proper,

the master creases. When the master clump is not

flat, the master is easily removed and creases.

* Adjust the master clump with the set screw on the

operation side.

1. Adjusting the clump parallelism

Adjustment procedure

1) Loosen the set screws on the clump plate and

shaft to adjust the parallelism.

NOTE :

Loosen the set screw on the

operation

side to adjust.

But do not loosen the set screw on

the lever shaft.

IMPORTANT :

2. Adjusting the clump flatness

Adjustment procedure

1) Cut the master, leaving 20mm wide piece at

three places, both sides and center. Have the

clump plate grip the three sections.

2) When the resistance for pulling the master out

is not stable, rotate the clump screw to adjust.

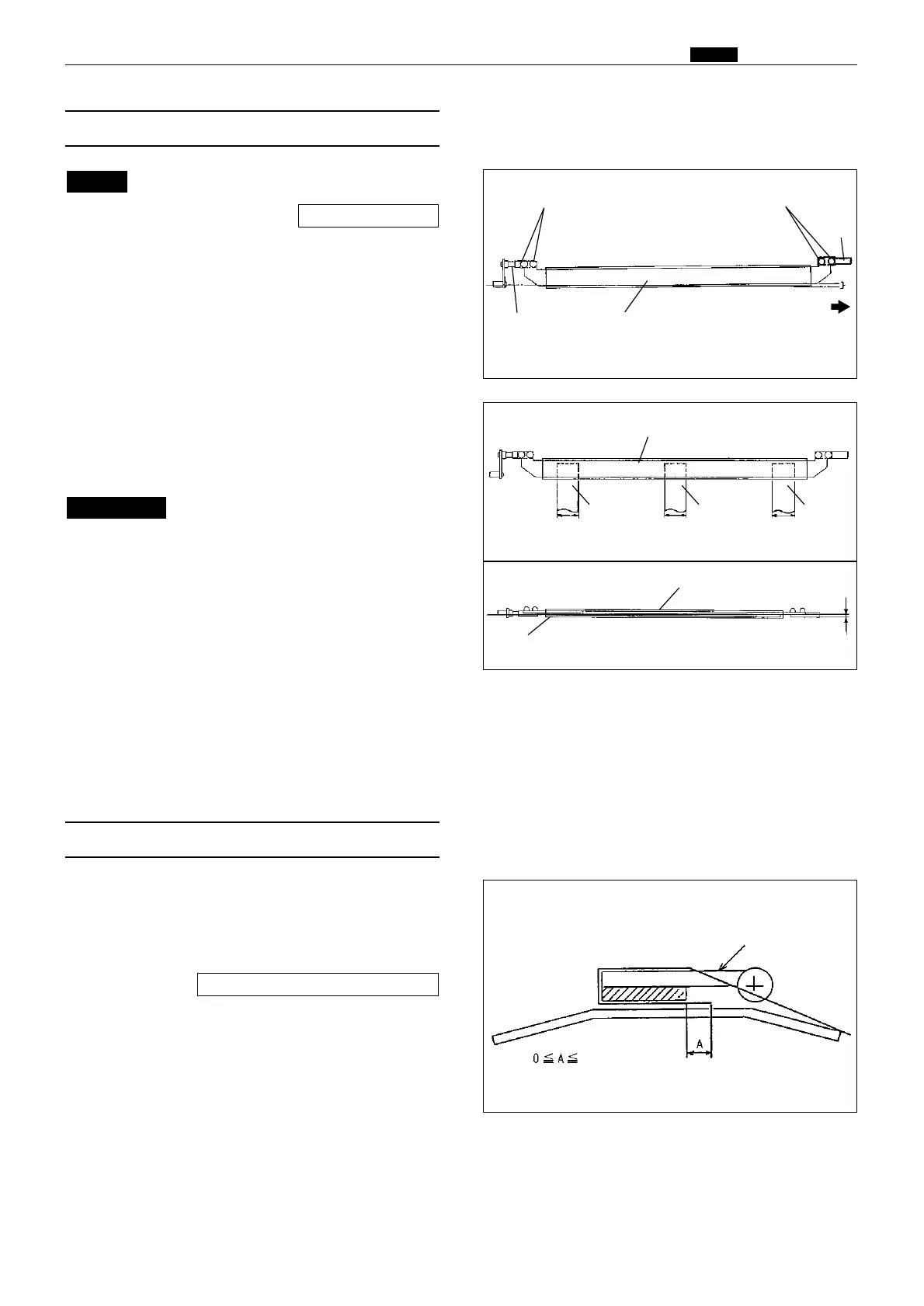

(4) Adjusting the Master Clump Section

Adjustment procedure

1) Adjust with HELP mode 29 so that the clump

amount of the master (A section in the figure) is

0~2mm with the master attached.

2) After HELP 29 adjustment, press the master set

switch and perform master set movement once.

(Be sure to remove all paper scraps.) Then

perform platemaking, and check the gripper

margin.

Set screws

Clump plate

Clump plate

Clump plate

Rubber magnet

Torsion

Master

20mm

Master Master

Operation side

Lever shaft

Set screws (for adjustment)

shaft

\See page 139

20mm 20mm

HELP mode H-29 \ see p.251

Master clump

2mm

Loading...

Loading...