JOB Entry

25

Programming a JOB on the Control Panel

2

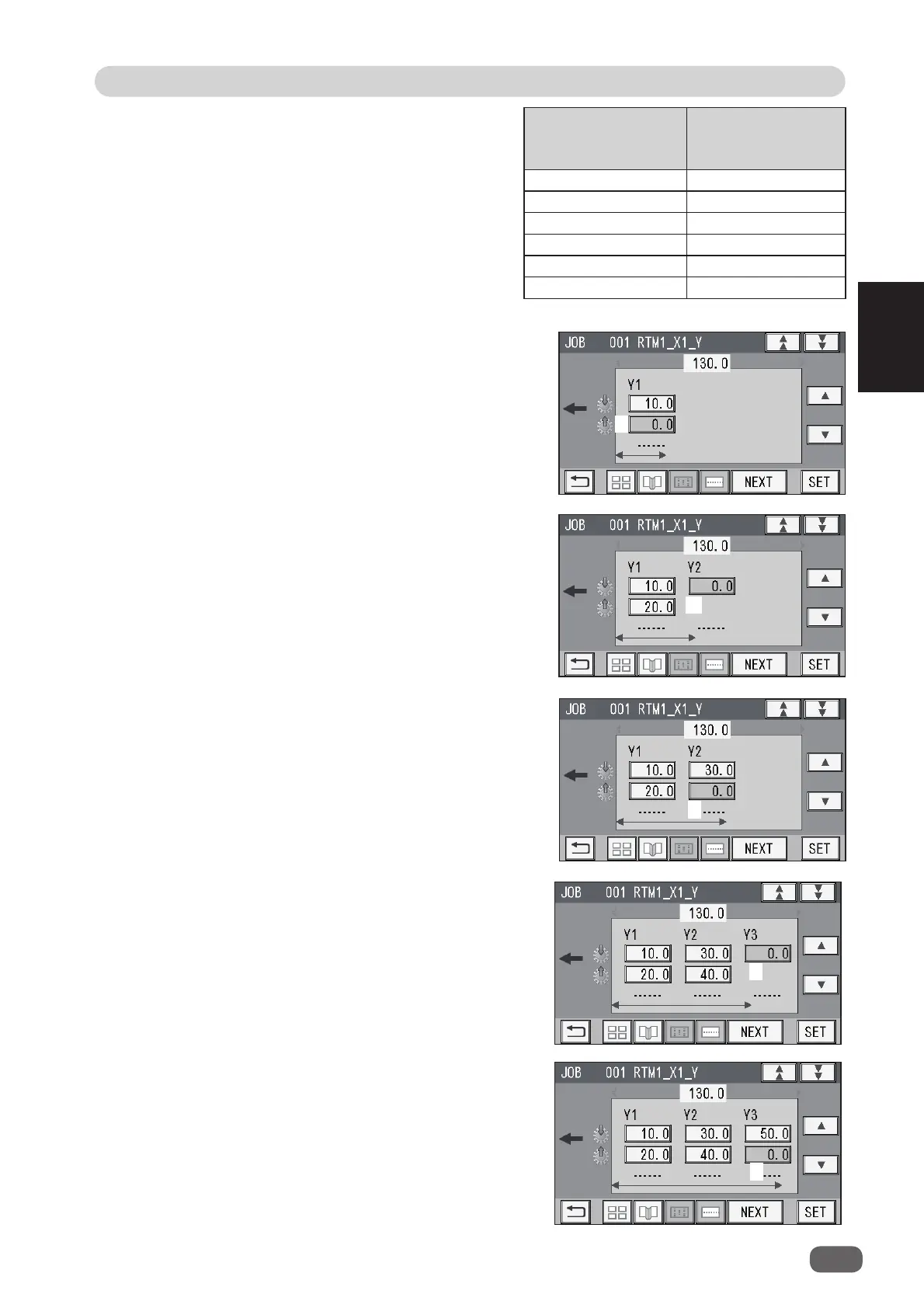

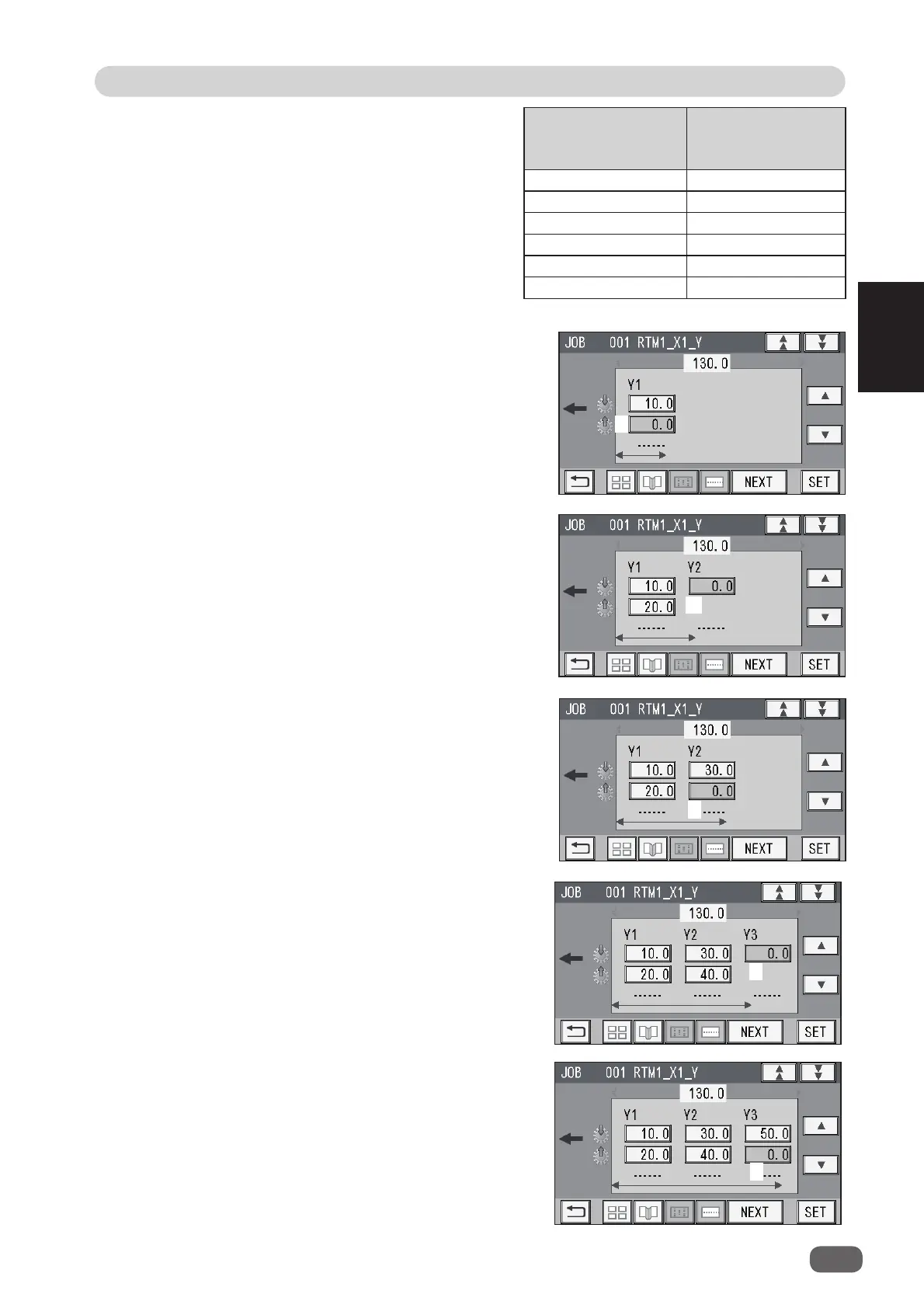

2. Enter the distance between the lead edge of

the fi nished product and

2

(

Off

position: the

processing stop position of the rotary tool) of

Y1

(

Set 1

in the Y direction) with the NUMERIC

keys.

Touch

SET

.

If the number of cards in the Y direction is 4 to 6,

go to step

17.

3. Enter the distance between the lead edge of

the fi nished product and

3

(

On

position: the

processing start position of the rotary tool) of

Y2

(

Set 2

in the Y direction) with the NUMERIC

keys.

Touch

SET

.

You can set up to six sets on one

document in the Y direction.

In

Wizard

, the number of sets that can be

set varies depending on the number of

cards in the Y direction.

Even if two

RTM (Rotary Tool Module)

s

are installed, the total of processing

positions

for one

RTM (Rotary Tool

Module)

is as shown in the table on the

right.

The number of cards

in the Y direction

Processing

positions of rotary

tool

1 Y1 to Y6 6 sets

2 Y1 to Y3 3 sets

3 Y1 to Y2 2 sets

4 Y1 1 set

5 Y1 1 set

6 Y1 1 set

2

3

4. Enter the distance between the lead edge of

the fi nished product and

4

(

Off

position: the

processing stop position of the rotary tool) of

Y2

(

Set 2

in the Y direction) with the NUMERIC

keys.

Touch

SET

.

If the number of cards in the Y direction is 3, go

to step 18.

6. Enter the distance between the lead edge of

the fi nished product and

6

(

Off

position: the

processing stop position of the rotary tool) of

Y3

(

Set 3

in the Y direction) with the NUMERIC

keys.

Touch

SET

.

If the number of cards in the Y direction is 2, go

to step

17.

5. Enter the distance between the lead edge of

the fi nished product and

5

(

On

position: the

processing start position of the rotary tool) of

Y3

(

Set 3

in the Y direction) with the NUMERIC

keys.

Touch

SET

.

4

6

5

Loading...

Loading...