Pressure supply

168 Service Instructions 745-35-10 S/745-35-10 A - 02.0 - 04/2017

If display reads S11+:

• Turn the screw (2) counterclockwise until the display reads S11-.

5. Exit Multi test I/O.

6. Pull up the pressure controller (4) and turn it until the pressure level is

at 6 bar.

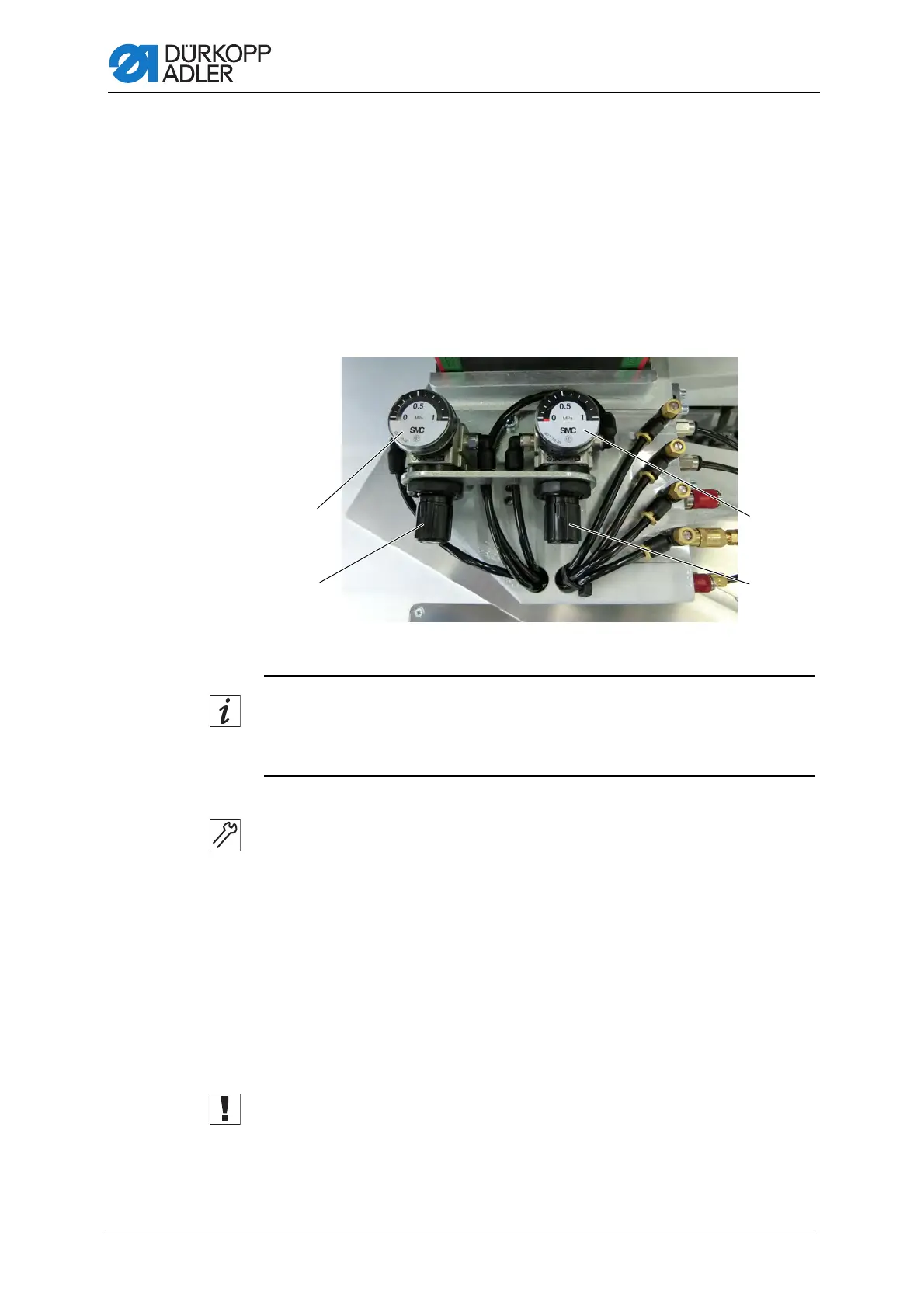

15.2 Setting the transport clamp control

Fig. 150: Setting the transport clamp control

Information

The downforce pressure can be adjusted separately for the right and the

left transport clamp depending on the type and thickness of the material.

To adjust the transport clamp control:

1. Turn the left pressure controller (2) to adjust the downforce pressure

of the transport clamp on the left.

The default setting is 0.5 Mpa = approx. 5 bar.

• Increase pressure: turn counterclockwise

• Reduce pressure: turn clockwise

2. Turn the right pressure controller (3) to adjust the downforce pressure

of the transport clamp on the right.

The default setting is 0.5 Mpa = approx. 5 bar.

• Increase pressure: turn counterclockwise

• Reduce pressure: turn clockwise

Important

The safe transport of the sewing material needs to be ensured at all times.

(1) - Pressure gage, left

(2) - Pressure controller, left

(3) - Pressure controller, right

(4) - Pressure gage, right

Loading...

Loading...