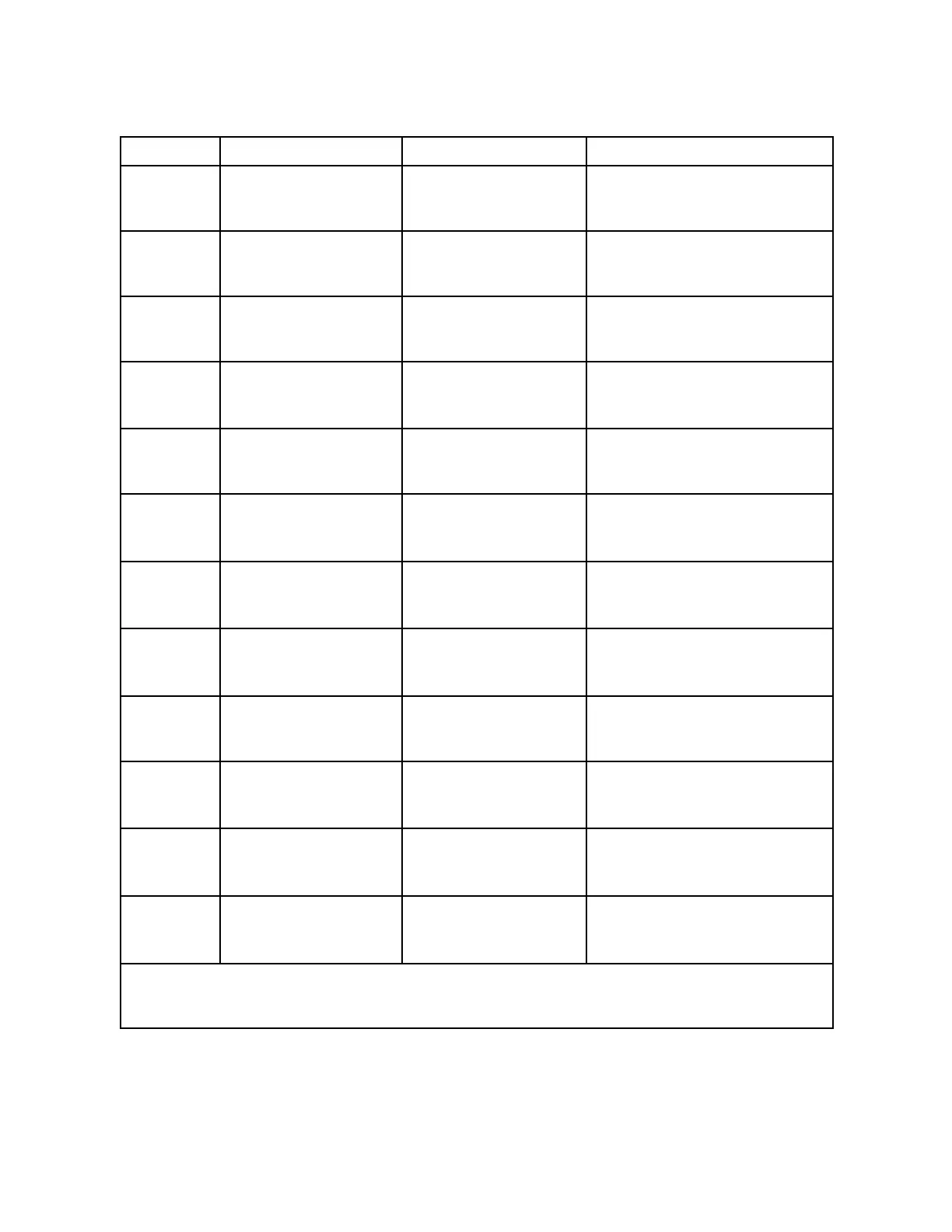

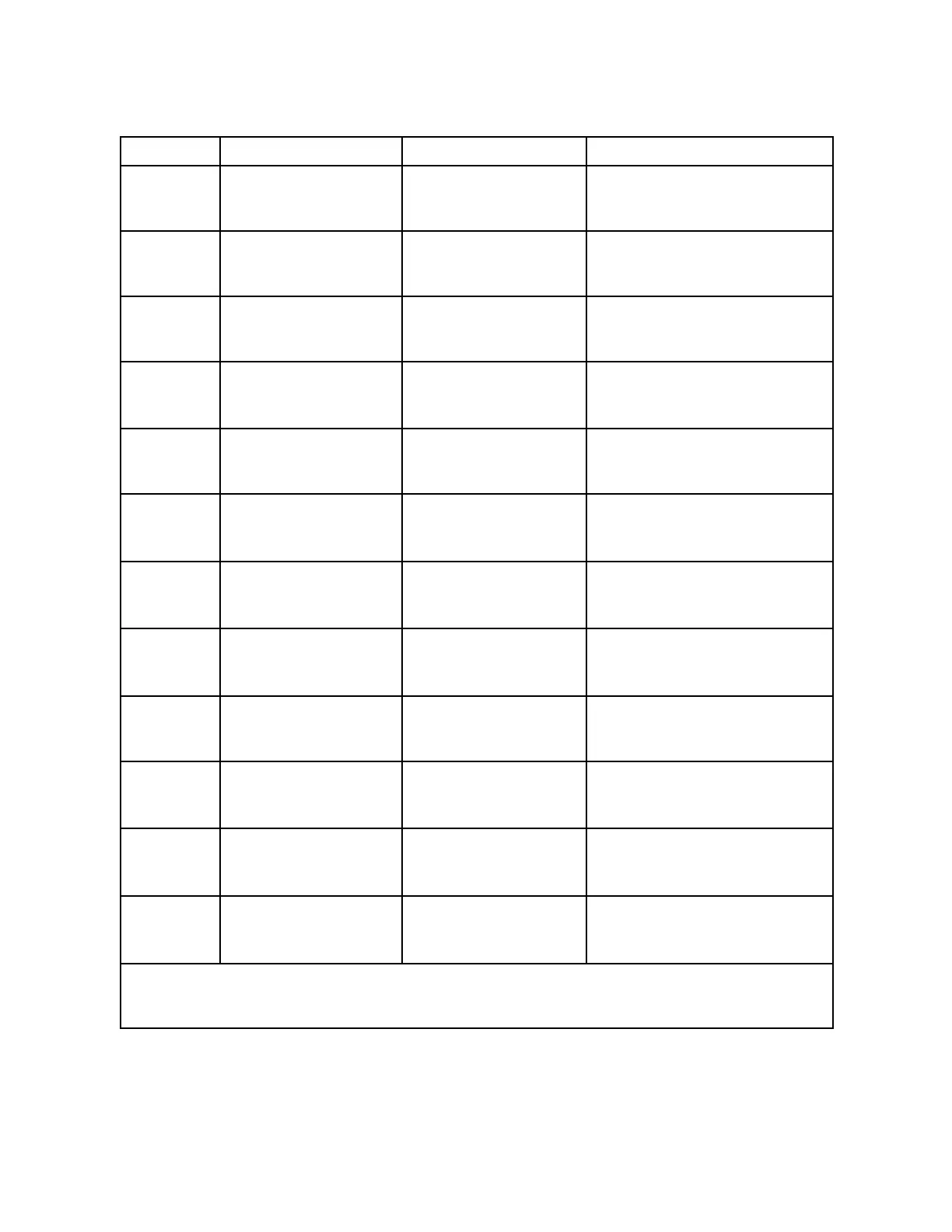

Operation

Table 4-1: Thermocouple Types in the Model 1140A

Type* Positive Wire Negative Wire Temperature Range

B-MN175

[B-MN125]

70% Pt – 30% Rh Alloy 94% Pt – 6% Rh Alloy

250°C to 1820°C

482°F to 3308°F

523.15 K to 2093.15 K

22.33°R to 3767.67°R

C 95% W – 5% Re Alloy 74% W – 26% Re Alloy

0°C to 2315.56°C

32°F to 4200.01°F

273.15 K to 2588.71 K

491.67°R to 4659.68°R

D 97% W – 3% Re Alloy 75% W – 25% Re Alloy

0°C to 2320°C

32°F to 4208°F

273.15 K to 2593.15 K

491.67°R to 4667.67°R

E-MN175

[E-MN125]

90% Ni – 10% Cr Alloy

(Chromel)

55% Cu – 45% Ni Alloy

(Constantan)

−270°C to 1000°C

−454°F to 1832°F

3.15 K to 1273.15 K

5.67°R to 2291.67°R

G 100% W 74% W – 26% Re Alloy

0°C to 2315.56°C

32°F to 4200.01°F

273.15 K to 2588.71 K

491.67°R to 4659.68°R

J-MN175

[J-MN125]

100% Fe

55% Cu – 45% Ni Alloy

(Constantan)

−210°C to 1200°C

−346°F to 2192°F

63.15 K to 1473.15 K

113.67°R to 2651.67°R

K-MN175

[K-MN125]

90% Ni – 10% Cr Alloy

(Chromel)

96% Ni – 2% Mn –

2% Al Alloy (Alumel)

−270°C to 1372°C

−454°F to 2501.6°F

3.15 K to 1645.15 K

5.67°R to 2961.27°R

N-MN175

[N-MN161]

84% Ni – 14% to 14.4%

Cr – 1.3% to 1.6% Si Alloy

95% Ni – 4.2% to 4.6% Cr

– 0.5% to 1.5% Mg Alloy

−270°C to 1300°C

−454°F to 2372°F

3.15 K to 1573.15 K

5.67°R to 2831.67°R

PLII

(Platinel II™)

Proprietary Platinum Alloy Proprietary Platinum Alloy

0°C to 1395°C

32°F to 2543°F

273.15 K to 1668.15 K

459.67°R to 3002.67°R

R-MN175

[R-MN125]

87% Pt – 13% Rh Alloy 100% Pt

−50°C to 1768.1°C [1767.6°C]**

−58°F to 3214.58°F [3213.68°F]

223.15 K to 2041.25 K [2040.75K]

401.67°R to 3674.25°R [3673.35°R]

S-MN175

[S-MN125]

90% Pt – 10% Rh Alloy 100% Pt

−50°C to 1768.1°C [1767.6°C]**

−58°F to 3214.58°F [3213.68°F]

223.15 K to 2041.25 K [2040.75K]

401.67°R to 3674.25°R [3673.35°R]

T-MN175

[T-MN125]

100% Cu

55% Cu – 45% Ni Alloy

(Constantan)

−270°C to 400°C

−454°F to 752°F

3.15 K to 673.15 K

5.67°R to 1211.67°R

* MN175 is NIST Monograph 175, which is based on ITS-90. When using IPTS-68, the thermocouple types are

those shown in [brackets], referencing NIST Monograph 125 and Monograph 161.

** The upper temperature limits for Types R and S are slightly lower in NIST Monograph 125 than in NIST

Monograph 175.

4-5

Loading...

Loading...