Chapter 3: Configuration and Commissioning

ModuLaser Modular Aspirating Smoke Detector Installation Manual 77

Smoke pellet test

This test is typically used for Class C installations.

Performing a smoke pellet test

1. Place a 20 x 20 cm (7.87 x 7.87 in.) metal plate onto a 5.8 KW butane gas

burner (or equivalent electrical heater), and then place a 7-9 g smoke pellet

onto the plate.

2. Place a metal chimney over the pellet. The chimney should be 2 to 6 mm

(0.08 to 0.24 in.) thick, at least 100 mm (3.94 in.) in diameter and 150 mm

(5.9 in.) high.

Either the base of the chimney or the metal plate should have ventilation

holes.

3. Ignite the burner and start the timer when the pellet starts to produce smoke.

4. Extinguish the burner after the required time has elapsed.

The amount of time depends on the room height and the temperature

differential (the temperature difference between the level at which the test is

conducted and the level at which the aspirating sampling points are

mounted). See Table 31 below.

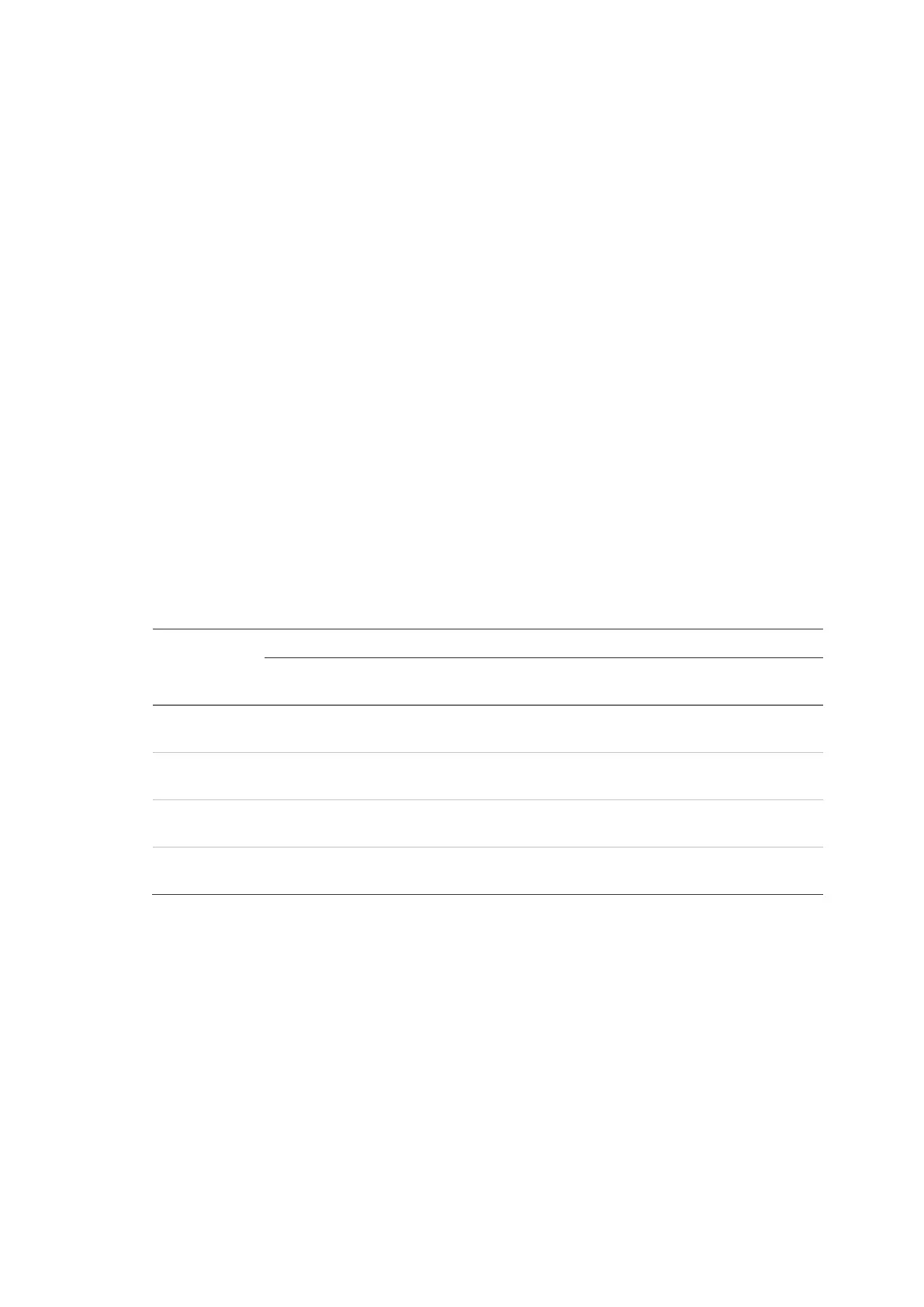

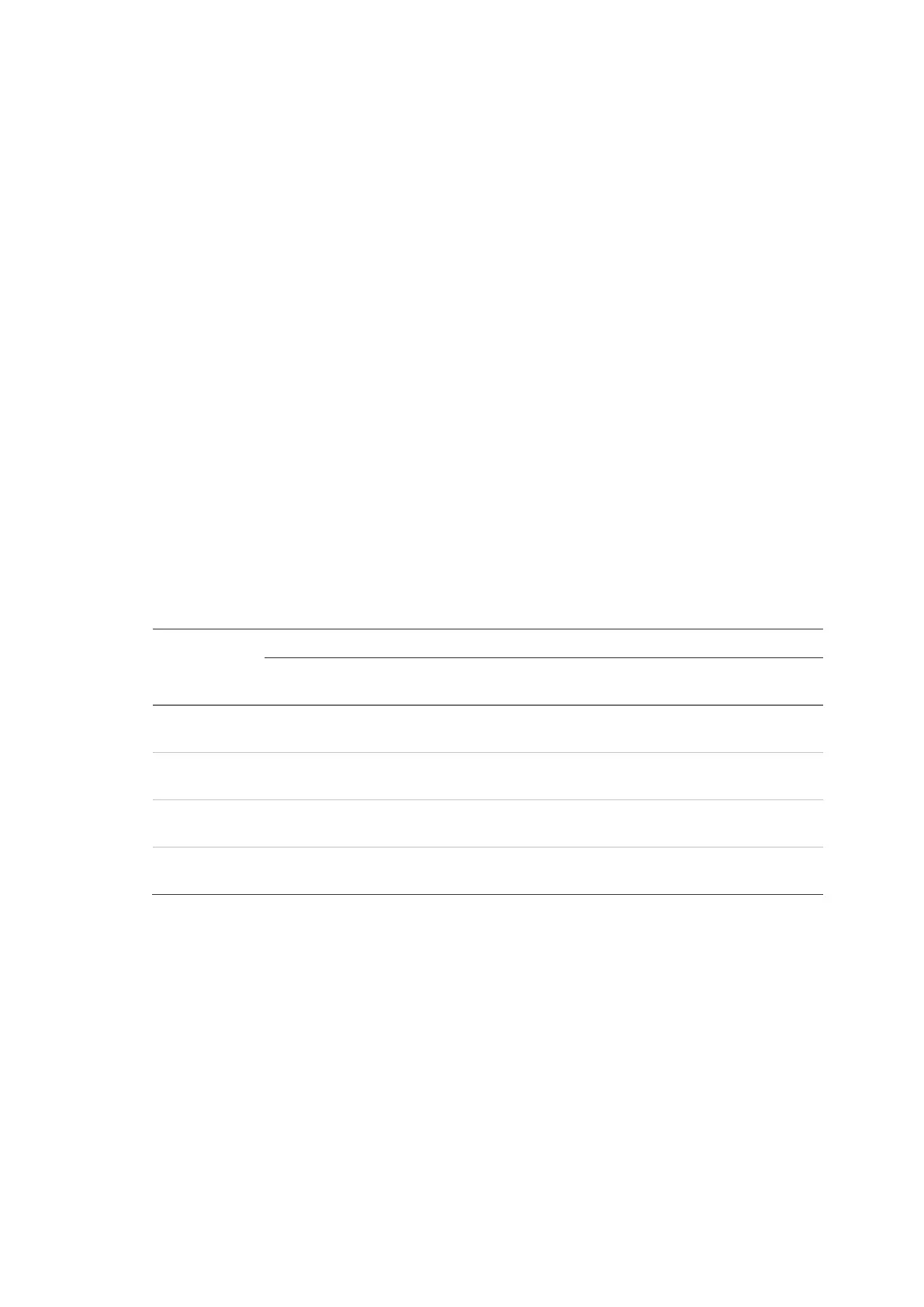

Table 31: Burn times for smoke pellet tests

Height

Temperature Differential

<3°C

(<37.4°F)

3 to 6°C

(37.4 to 42.8°F)

6 to 9°C

(42.8 to 48.2°F)

9 to 12°C

(48.2 to 53.6°F)

12 to 15°C

(53.6 to 59°F)

3 to 5 m

(9.8 to 16.4 ft.)

3s 6s 9s 12s 17s

5 to 10 m

(16.4 to 32.8 ft.)

7s 13s 20s 27s 34s

10 to 15 m

(32.8 to 49.2 ft.)

10s 20s 30s 40s 51s

15 to 20 m

(49.2 to 65.6 ft.)

13s 27s 40s 54s 67s

Connectivity check

Ensure that communications between the detector and any fire control and

indicating equipment (especially alarm and fault conditions) operate correctly.

Check any other cause and effect requirements, particularly in relation to

integration with automatic suppression systems.

Loading...

Loading...