▪ Ensure the maintenance is done by a suitably trained and supervised technician.

Obe

y local and naonal safety requirements.

▪ Ensure the maintenance technician is familiar with the safety procedures which

relate to the products processed by the pumping system.

▪ Check that all the required parts are available and are of the correct type before

starng work.

▪ Isolate the pump and other components from the electrical supply to prevent

accidental operaon.

▪ Allow the pump to cool for at least 3 hours before starng maintenance work.

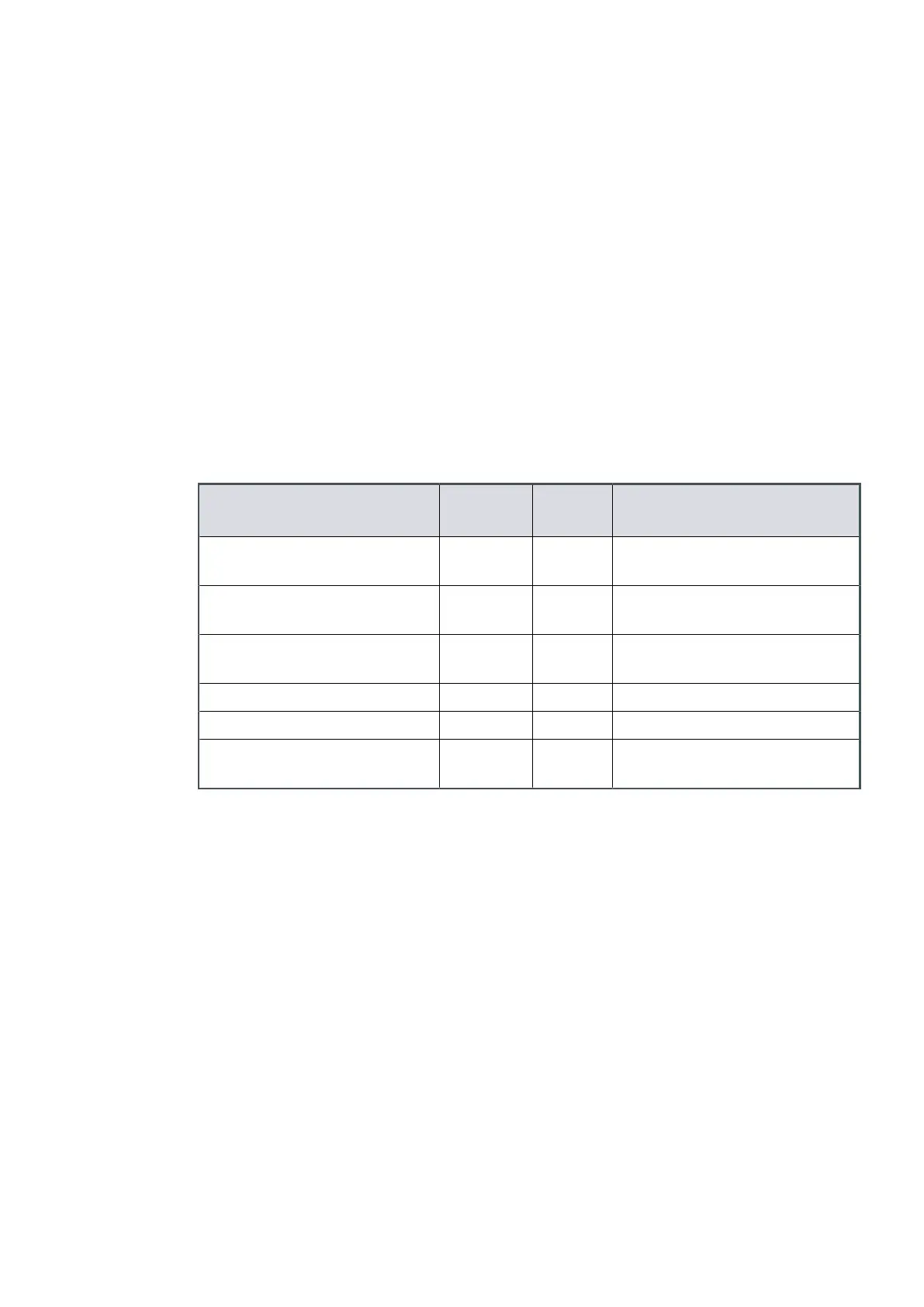

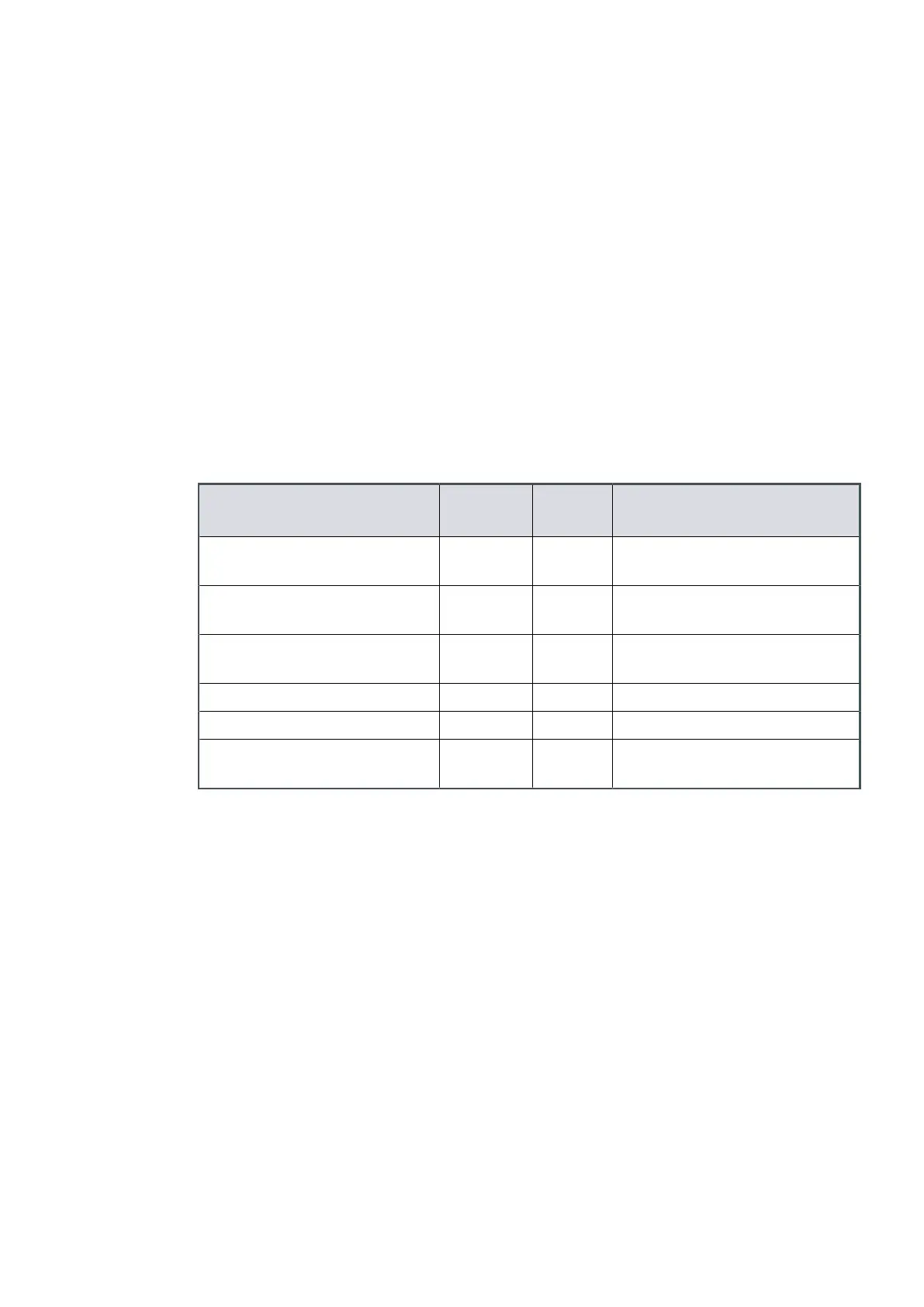

6.2 Maintenance plan

More frequent maintenance may be required if the pump is used to pump aggressive

gases or vapours, such as solvents, organic substances and acids, or if the pump is

operated connuously at the higher end of its operang temperature.

Table 14

Maintenance plan

Operaon

Frequency

(months)

Service

indicator

Secon reference

Inspect and clean the inlet

strainer

12 No

Inspect and clean the inlet

strainer on page 39

Inspect and clean the external

fan cover if required

12 No

Clean the external fan cover on

page 39

Check the pump performance 30 Yes

Check the pump performance

(service indicator) on page 40

Replace the pump bearings 60 Yes Replace the p-seals on page 40

Replace the pump controller 120 Yes Replace the p-seals on page 40

Electrical safety check 60 No

Replace the pump controller

(service indicator) on page 41

For service indicator codes, refer to Service indicator codes on page 41.

6.3 Inspect and clean the inlet strainer

Whenever the pump is disconnected from the vacuum system, or on an annual basis, we

recommend:

▪ Removing the inlet strainer from the pump inlet (refer to Figure: nXDS scroll pump

on page 11) and remove any debris that may have accumulated.

▪ Inspecng the inlet strainer and if necessary, clean it with a cleaning soluon

suitable for the substances pumped. Ret the inlet strainer before reconnecng

the pump to the vacuum system. Refer to Connect to the vacuum system on page

28.

6.4 Clean the external fan cover

If the fan cover is not kept clean, the air ow over the pump can be restricted and the

pump may overheat.

Page 39

A73501880_G - Maintenance

Loading...

Loading...