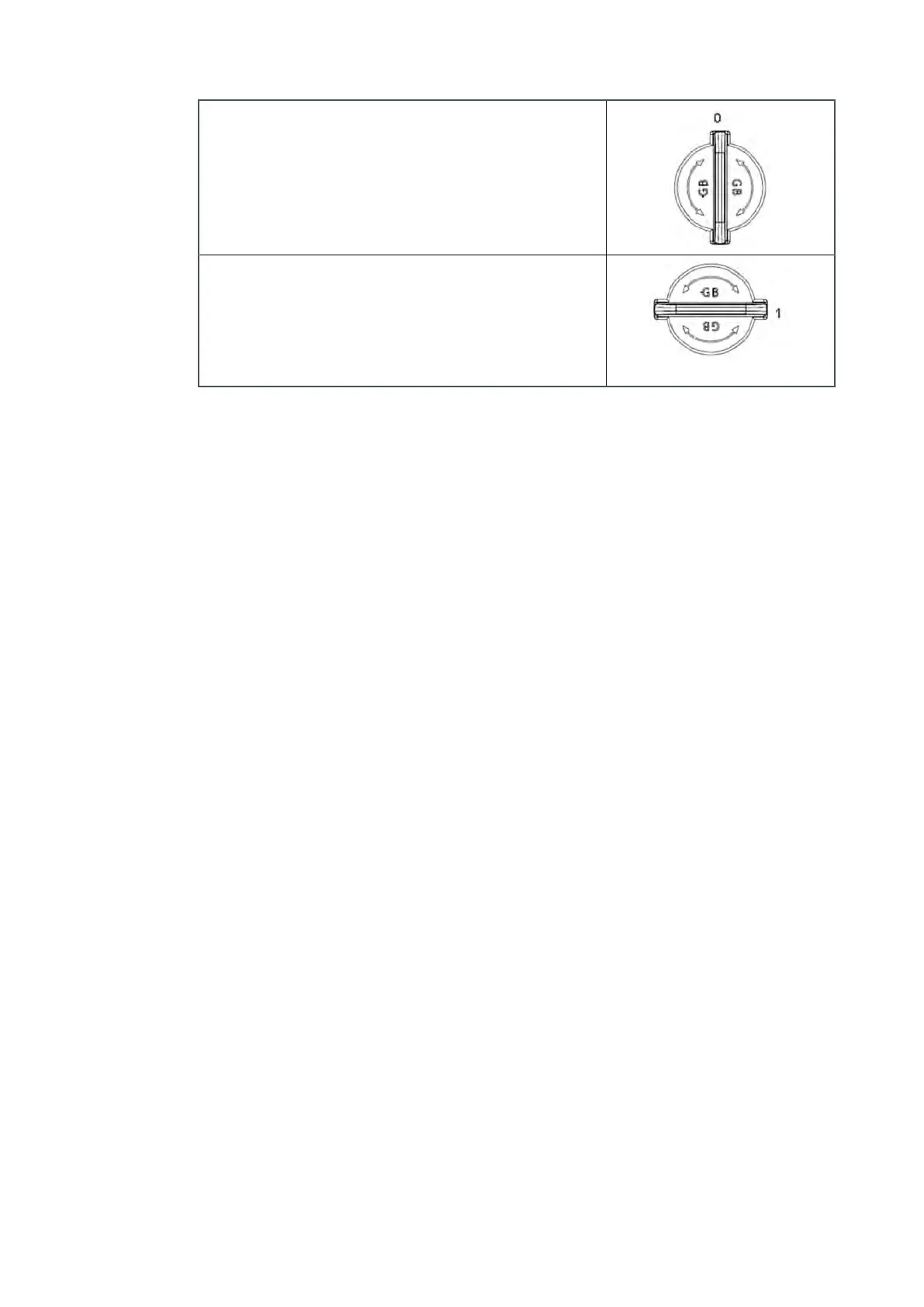

Gas ballast OFF (posion 0). Use this seng t

o:

• achieve ulmate vacuum

• pump dry gases.

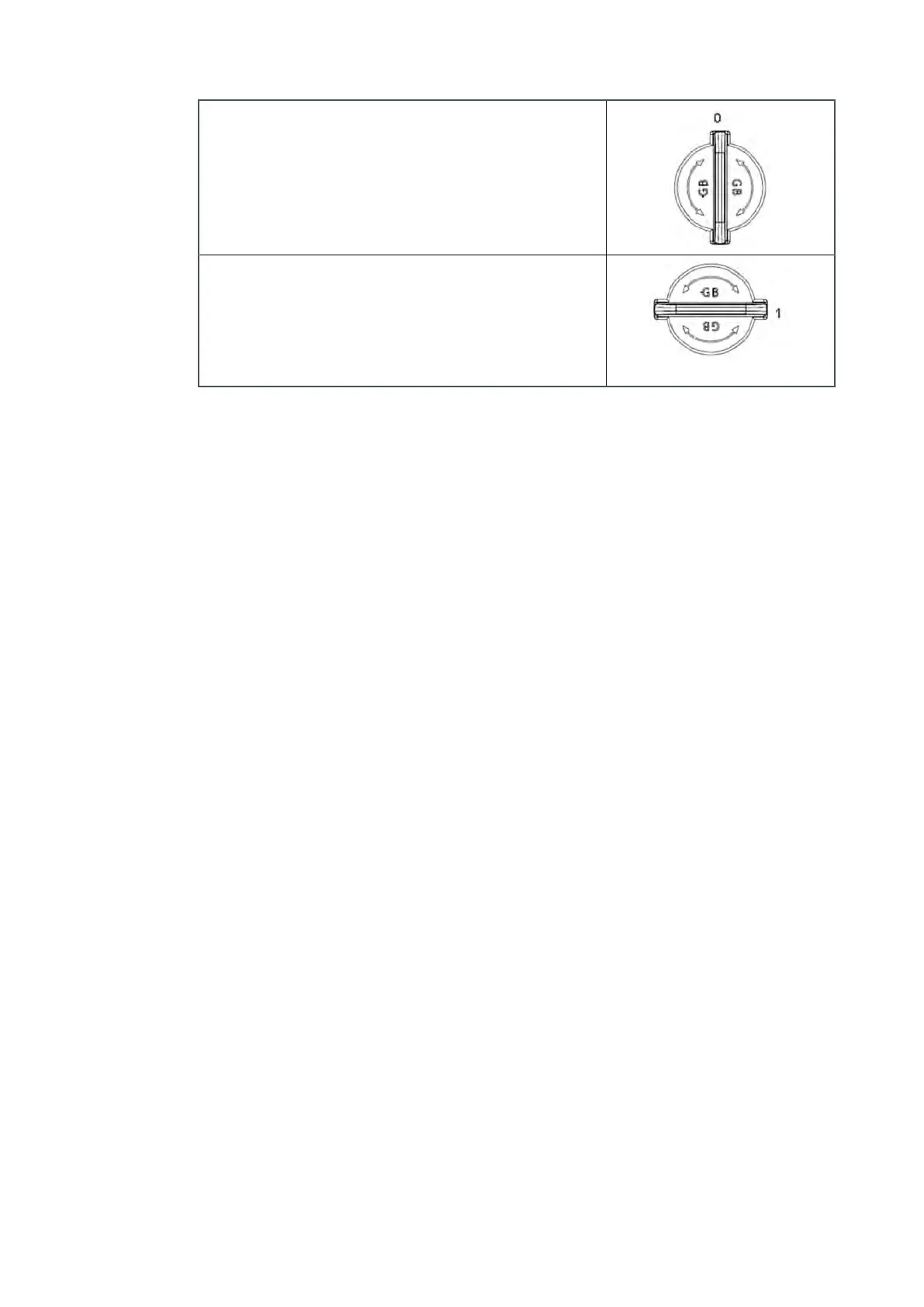

Gas ballast ON (posion 1). Use this seng t

o:

• pump low concentraons of condensable

vapours

• decontaminate the pump.

5.7 Start up procedure

Use the pr

ocedure below to start up the pump:

1. Ensure that any vacuum system isolaon valve is closed (if ed).

2. With the mains supply to the pump isolated, connect a recommended lead to the

electrical socket on the pump (refer to Figure: nXDS scroll pump on page 11).

3. Apply power.

4. Start the pump system using the appropriate control source, that is, using the Start

buon in manual c

ontrol mode (refer to Figure: User interface panel on page 32);

the Start/Stop control input (refer to Table: Logic interface connector pins on page

22, pin 3) in parallel control mode or a Start command in serial control mode.

5. Open the vacuum system isolaon valve, if ed.

5.8 To achieve ulmate vacuum

In order to achieve the best possible vacuum, the pump should be operated with the gas

ballast control turned o. However, if the pump, or elements of the vacuum system it is

aached to, are new or have been newly ed, some atmospheric moisture may be

present. If atmospheric moisture is present, run the pump with gas ballast on for

20 minutes before turning gas ballast o. If moisture ican remain, the performance of

the pump will be impaired.

5.9 To pump condensable vapours

Select gas ballast ON when there is a high proporon of condensable vapours in the

process gases. This will assist the vapours to pass through the pump without condensing

and keep the pump performance from degrading.

5.10 Shut down

Use the procedure below to shut down the pump:

1. If shung the pump do

wn prior to a period of storage, remove any process gases

by running on a gas ballast for at least one hour.

Page 36

A73501880_G - Oper

aon

Loading...

Loading...