31

WWW.EILERSEN.COM

Appendices

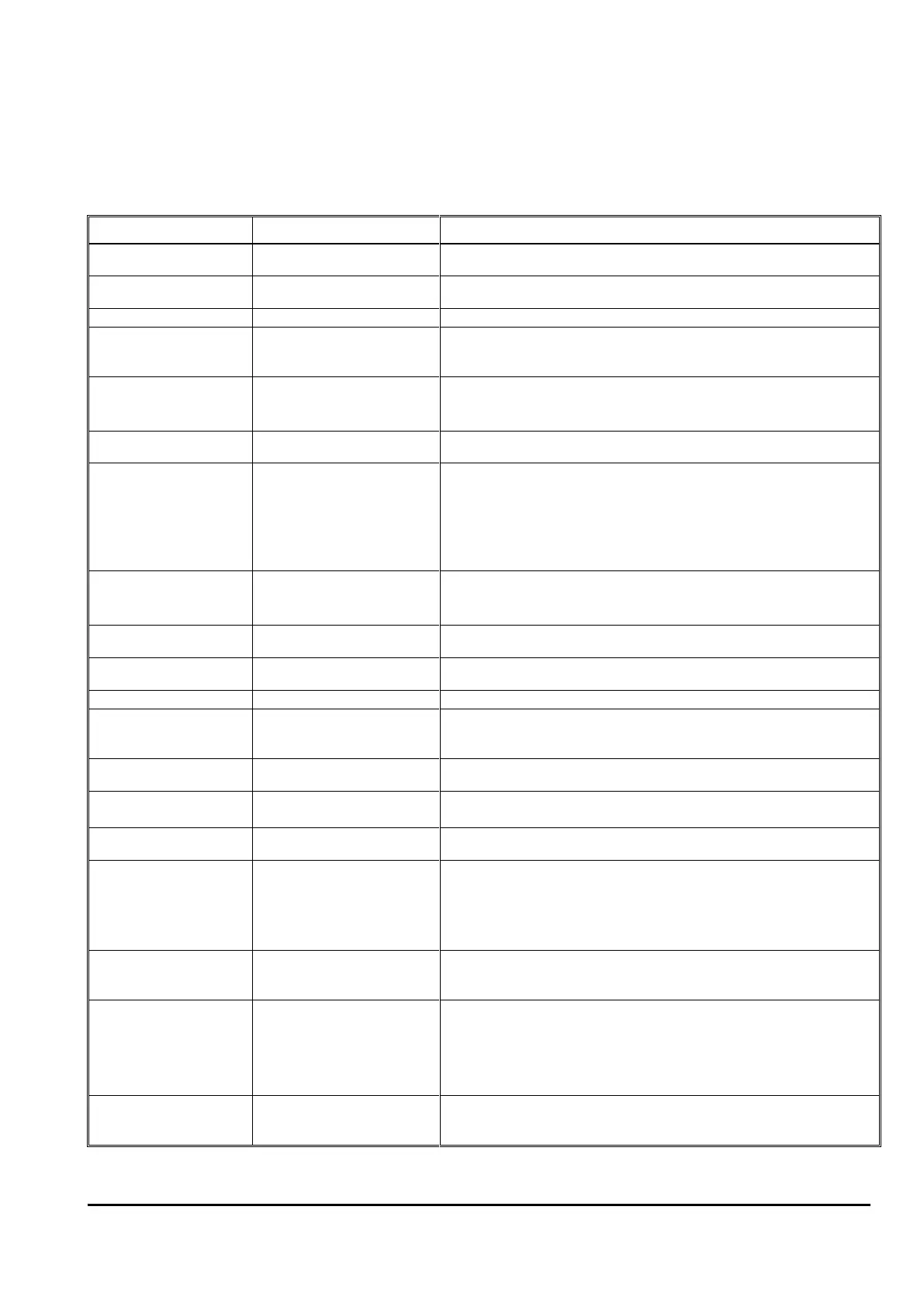

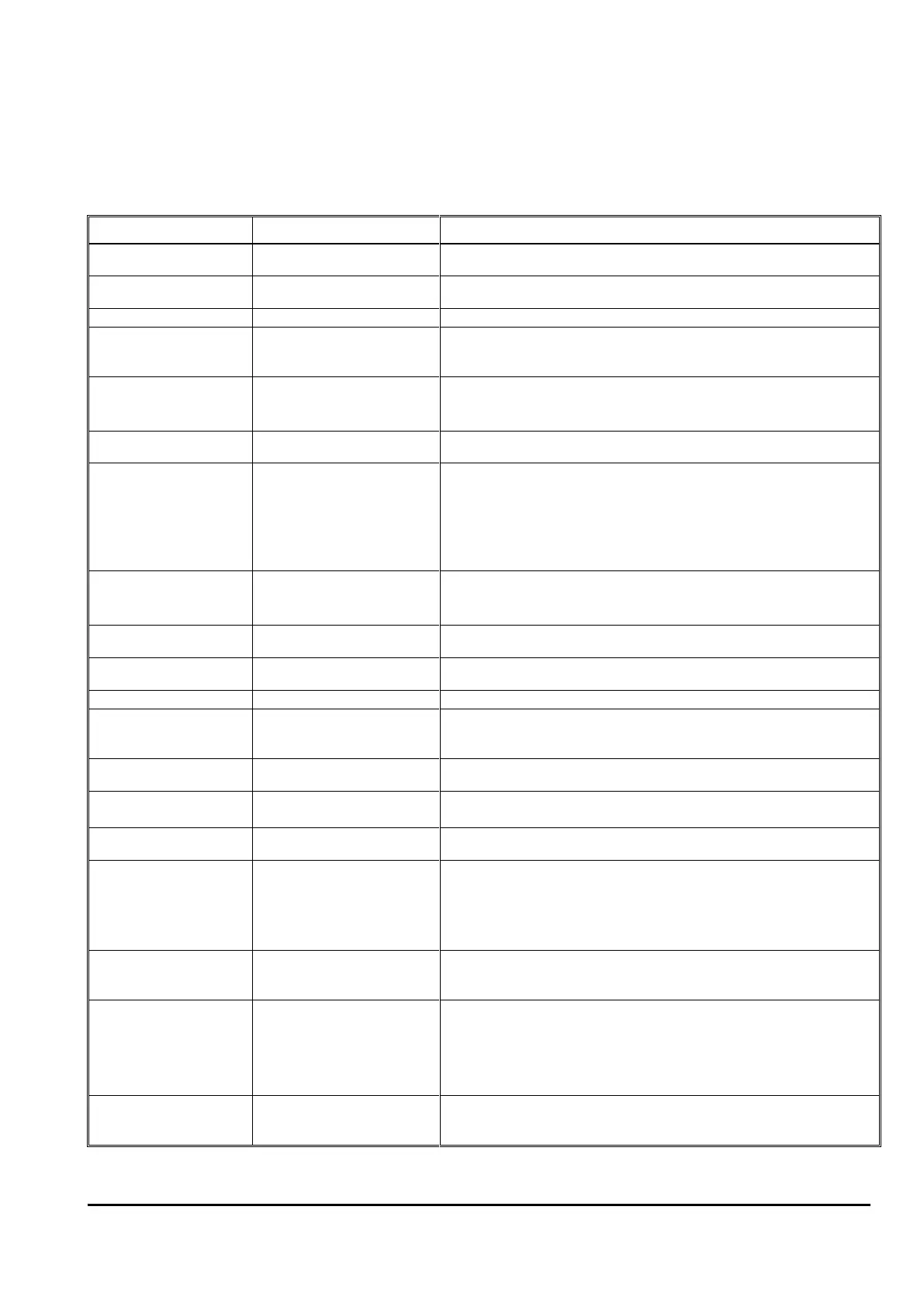

Appendix A – Installation checklist

1. Check electrical connec-

tions

Power, Load cells, Digital I/O, RS485 (external modules), analog output (4-

20mA or 0-10V) and Ethernet.

2. Apply power and check

software ID

Software: StdLim.140630.5.7.

Parameters: <Locked / Unlocked>

4. Intelligent Setup?

(Optional)

Intelligent Setup: Possible activation of Intelligent Setup feature for auto-

matic proposal of weighing technical parameters below.

See separate ’Intelligent Setup’ manual for further information.

5. Configure load cells

used

ServiceMode -> Weighing ->

Load Cells

Protocol type: <Protocol type: 2010/401x/4x40-StdBB/4x40-StdLC>

No.: <Number of connected load cells>

Supports: <Number of supporting points>

6. Power off/on and check

load cells

SystemInfo -> Load Cell Signals

Load Cell Signals: Verify all load cells found without error indications?

7. Configure the 3 weigh-

ing ranges

Mode: NORMAL / CALIBRATION / PROTOCOL each consisting of:

- Unit: <Desired unit>

- DP: <Number of digits after decimal point>

- Resolution: <Desired resolution>

- Minimum: <Desired minimum weight>

- Maximum: <Desired maximum weight>

8. Configure display and

filtering

ServiceMode -> Weighing ->

Display

Interval: <Measuring period. Default: 400ms>

Filters: <Sample, Display and Steady filters. Default: None>

Steady detection limit: <Value for steady detection. Default: 1 division>

ServiceMode -> Weighing ->

Coarsetare

Perform coarsetare with no load on weighing arrangement.

10. Configure zero track-

ing range

ServiceMode -> Weighing ->

Zeroing

ZT range: <Range for automatic zero tracking. Default: ½ division>

Verify weight reading with known load.

12. Perform corner cali-

bration

(Optional)

ServiceMode -> Weighing ->

Calibration -> Corner.Cal.

Perform corner calibration if needed.

13. Perform system/span

calibration

ServiceMode -> Weighing ->

Calibration

Perform calibration of system/span. Note calibration factor.

14. Perform linearization

(Optional)

ServiceMode -> Weighing ->

Linearization

Perform linearization (Up/Down correction) if needed.

15. Perform final load

check

Verify weight reading with known load if necessary.

16. Configure analog

output

(Possible option)

Output: <Analog output type: 4-20mA or 0-10V>

Value: <Analog output follows: Gross or Net weight>

Full scale: <Value resulting in maximum analog signal>

Error value: <Output value on error: Maximum or Minimum>

Test mode/value: <Used for test to force an output signal>

17. Configure Ethernet

connection

(Optional)

ServiceMode -> Ethernet

( -> Protocols)

Configure Ethernet connection (IP, subnet and protocol) on Ethernet con-

nector of the 5024 if needed.

18. Configure external

module

(Possible option)

ServiceMode -> Ext.Module

Configure the connection of any external module on the RS485 channel if

needed:

- MCEXX35: Profibus-DP module

- MCE9637: DeviceNet module

- 2X50: Ethernet module

- 2070: PROFINET module

19. Configure system

specifics

(Optional)

ServiceMode -> Dosing par.

(possibly other screens as well)

Configure system specific parameters (dosing, afterflow, etc.).

Loading...

Loading...