Cerabar M, Deltabar M, Deltapilot M Commissioning with the FF configuration program

Endress+Hauser 149

Calibration without reference pressure – dry calibration

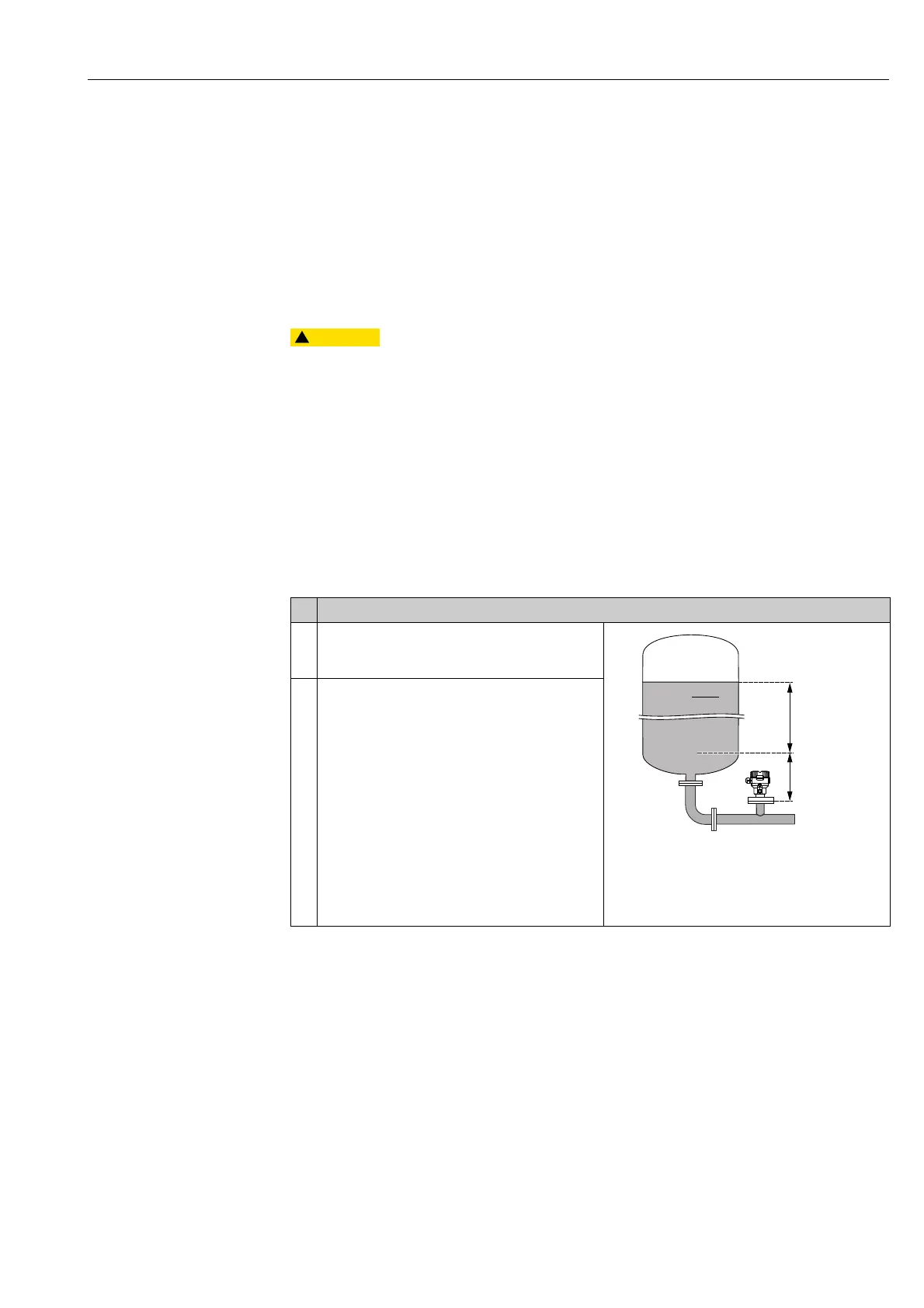

Example:

In this example, the volume in a tank should be measured in liters. The maximum volume of

1000 liters corresponds to a pressure of 450 mbar. The minimum volume of 0 liters

corresponds to a pressure of 50 mbar since the device is mounted below the level lower-

range value.

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• This is a theoretical calibration i.e. the pressure and volume values for the lower and upper

calibration point must be known.

Note Dependencies when setting parameters!

‣ The values entered for Empty calibration/LOW_LEVEL_EASY and Full calib./

HIGH_LEVEL_EASY must be at least 1% apart for the "Level easy pressure" level mode.

The value will be rejected, and a warning message displayed, if the values are too close

together. Further limit values are not checked; i.e. the values entered must be

appropriate for the sensor and the measuring task so that the measuring device can

measure correctly.

‣ Due to the orientation of the device, there may be a shift in the measured value, i.e. when

the container is empty, the Primary Value/PRIMARY_VALUE parameter does not display

zero.

For information on how to perform position adjustment, see also ä 144,

"Pos. zero adjust/PRESSURE_1_ACCEPT_ZERO_INSTALL".

Description

1 Deltabar M: Before configuring the device for your

application, the pressure piping must be cleaned and

filled with medium.

A0030030

Fig. 42: Calibration without reference pressure –

dry calibration

A See Table, Step 9.

B See Table, Step 8.

2 Open the Pressure Transducer Block and set the

block

mode to OOS.

B

1000 l

450 mbar

A

0 l

50 mbar

Loading...

Loading...