132

WSG-1068 ENGINE

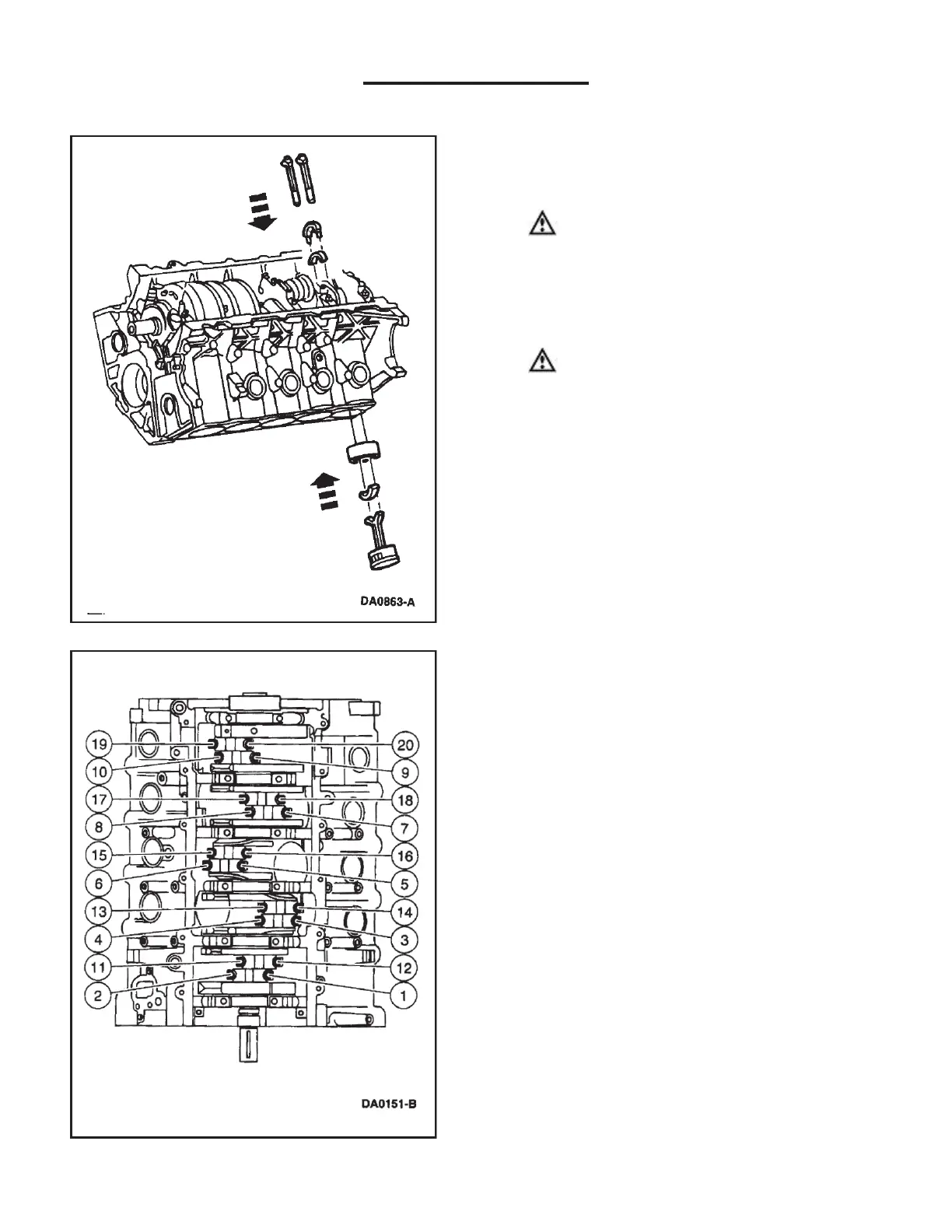

11. Use the Connecting Rod Guide Tool and Piston Ring

Compressor to install the piston and connecting rod

assembly.

12.

CAUTION: Do not scratch the cylinder walls

or crankshaft journals with the connecting rod

(6200).

Once the connecting rod is seated on the crankshaft

journal, remove the connecting rod guide tools.

13.

CAUTION: The rod cap installation must

keep the same orientation as marked during

disassembly.

NOTE: The connecting rod caps are of the “cracked’’

design and must mate with the connecting rod ends.

Excessive bearing clearance will result if not mated

properly.

Install the connecting rod bearings, position the

connecting rod cap and loosely install the two new

bolts.

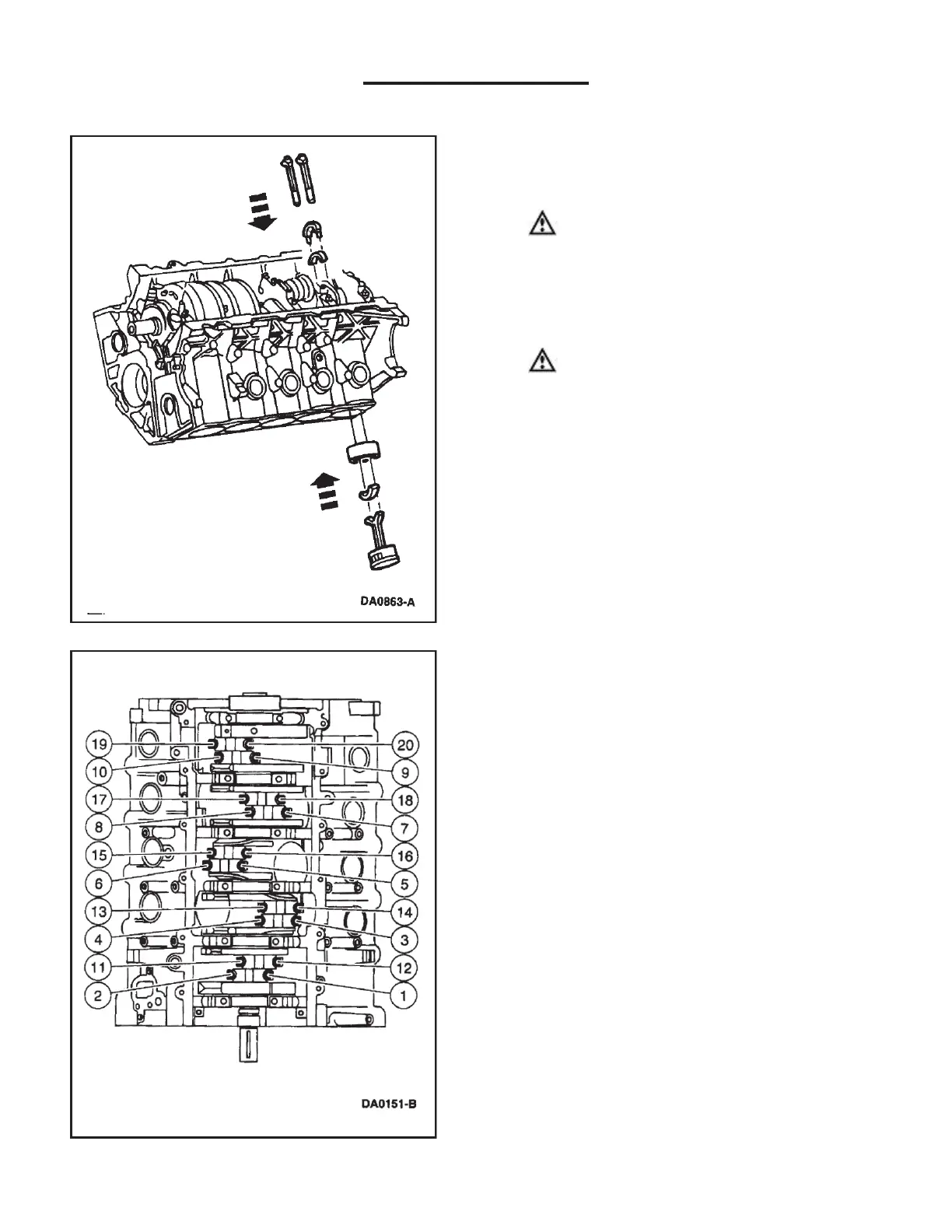

14. NOTE: Be sure to tighten the bolts in two stages.

Tighten the connecting rod bolts in the sequence

shown.

Stage 1: Tighten to 40-45 Nm (30-33 lb/ft).

Stage 2: Tighten an additional 90 degrees to 120

degrees.

15. Rotate the crankshaft and repeat the procedure to

position each connecting rod at bottom dead center

until all bolts are tightened to specification.

Loading...

Loading...