167

WSG-1068 IGNITION SYSTEM

The Fuel Select Switch

In the event that the engine is operated on alternate

fuels such as natural gas, compressed natural gas

(CNG), or liquefied petroleum gas (LPG), timing can be

modified with a Fuel Select Switch.

NOTE: Fuel select switch is supplied by the customer.

Sends a signal to the GCP to adjust base timing

for alternate fuel

Is manually controlled.

With this system, the GCP monitors the engine load,

speed, operating temperature, air intake temperature

and decides what degree of spark advance is correct for

all of the operating conditions. Because timing is set for

life inherently in the design of the engine, and there are

no moving parts in the ignition system itself, no

maintenance is required except for periodic spark plug

checks. The system provides for fixed spark advance at

start-up, for cold weather starting, and for “average

value” default settings in case of component failure.

Particular attention has been given to spark optimization

for excellent fuel economy and power in the warm-up

mode.

The spark plugs are paired so that one plug fires during

the compression stroke and its companion plug fires

during the exhaust stroke. The next time that coil is fired,

the plug that was on exhaust will be on compression,

and the one that was on compression will be on exhaust.

The spark in the exhaust cylinder is wasted but little of

the coil energy is lost.

Run Mode

The GCP interprets engine speed above100 RPM as

Run Mode.

The Base Spark Advance (BSA) is calculated by the

(GCP) module processing the engine speed and load

plus sensors mentioned in operation of this section and

Fuel Select Switch.

Inputs to the GCP Effecting the Ignition

The spark strategy is based on sensors and manifold

vacuum input to the GCP module, which include the

following inputs:

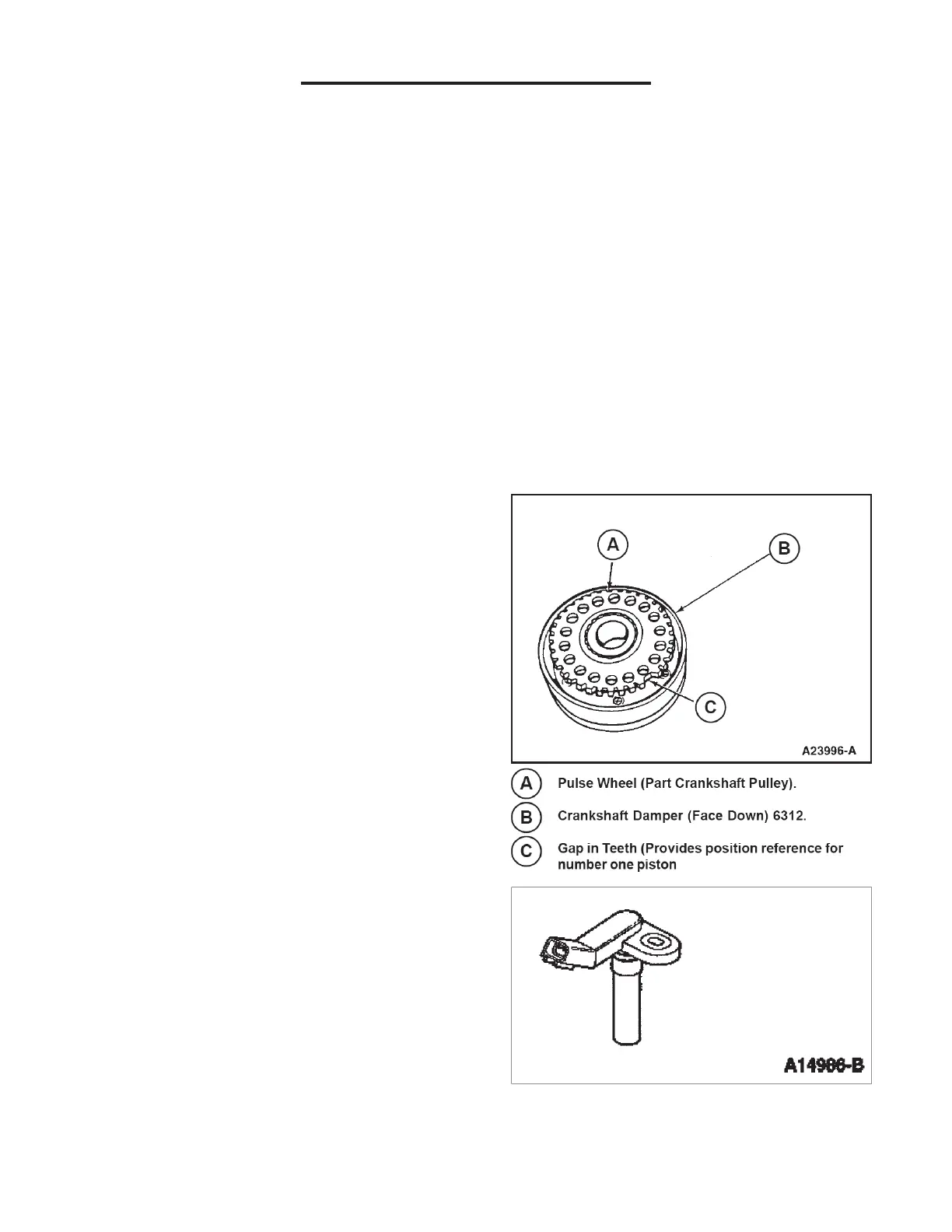

Crankshaft Position Sensor (CKP Sensor)

The CKP sensor is a magnetic transducer mounted on

the engine block adjacent to a pulse wheel located on

the crankshaft. By monitoring the crankshaft mounted

pulse wheel A , the CKP is the primary sensor for

ignition information to the GCP. The pulse wheel located

behind the crankshaft pulley B , has a total of 39 teeth

spaced 9 degrees apart with one empty space C for a

missing tooth. An A/C voltage signal is generated which

increases with engine rpm and provides engine speed

and crankshaft position information to the GCP. By

monitoring the pulse wheel, the CKP sensor signal

indicates crankshaft position and speed information to

the GCP. The CKP sensor is also able to identify piston

travel in order to synchronize the ignition system and

provide a way of tracking the angular position of the

crankshaft relative to a fixed reference for the CKP

sensor configuration. GCP also uses the CKP signal to

determine if a misfire has occurred by measuring rapid

decelerations between teeth.

Loading...

Loading...