166

WSG-1068 IGNITION SYSTEM

Overview

The Ignition System is designed to ignite the

compressed air/fuel mixture in an internal combustion

engine by a high voltage spark from an ignition coil. The

ignition system also provides engine timing information

to the GCP for proper engine operation and misfire

detection.

Electronic Ignition System

The Coil On Plug (COP) EI System uses a separate coil

per spark plug and each coil is mounted directly onto the

plug. The COP EI System eliminates the need for spark

plug wires but does require input from the camshaft

position (CMP) sensor. Operation of the components are

as follows:

1. Note: Electronic Ignition engine timing is entirely

controlled by the GCP. Electronic Ignition engine

timing is NOT adjustable. Do not attempt to

check base timing. You will receive false

readings.

2. The GCP uses the CMP sensor not shown on

COP EI Systems to identify top dead center of

compression of cylinder 1 to synchronize the

firing of the individual coils.

3. The GCP acts as an electronic switch to ground

in the coil primary circuit. When the switch is

closed, battery positive voltage (B+) applied to

the coil primary circuit builds a magnetic field

around the primary coil. When the switch opens,

the power is interrupted and the primary field

collapses inducing the high voltage in the

secondary coil windings and the spark plug is

fired. A kickback voltage spike occurs when the

primary field collapses.

4. The GCP processes the CKP signal and uses it

to drive the tachometer as the Clean Tach Out

(CTO) signal.

Starting RPM

The program strategy requires the engine to obtain a

minimum of 100-140 RPM before the GCP will allow

ignition spark to be generated. Any failure with an

auxiliary system can cause excessive engine crank

(load) force, which may cause the engine too not reach

the required starting RPM. Perform a thorough

inspection of all auxiliary systems and components,

inspect for binding hydraulic pumps and misalignment of

drive systems.

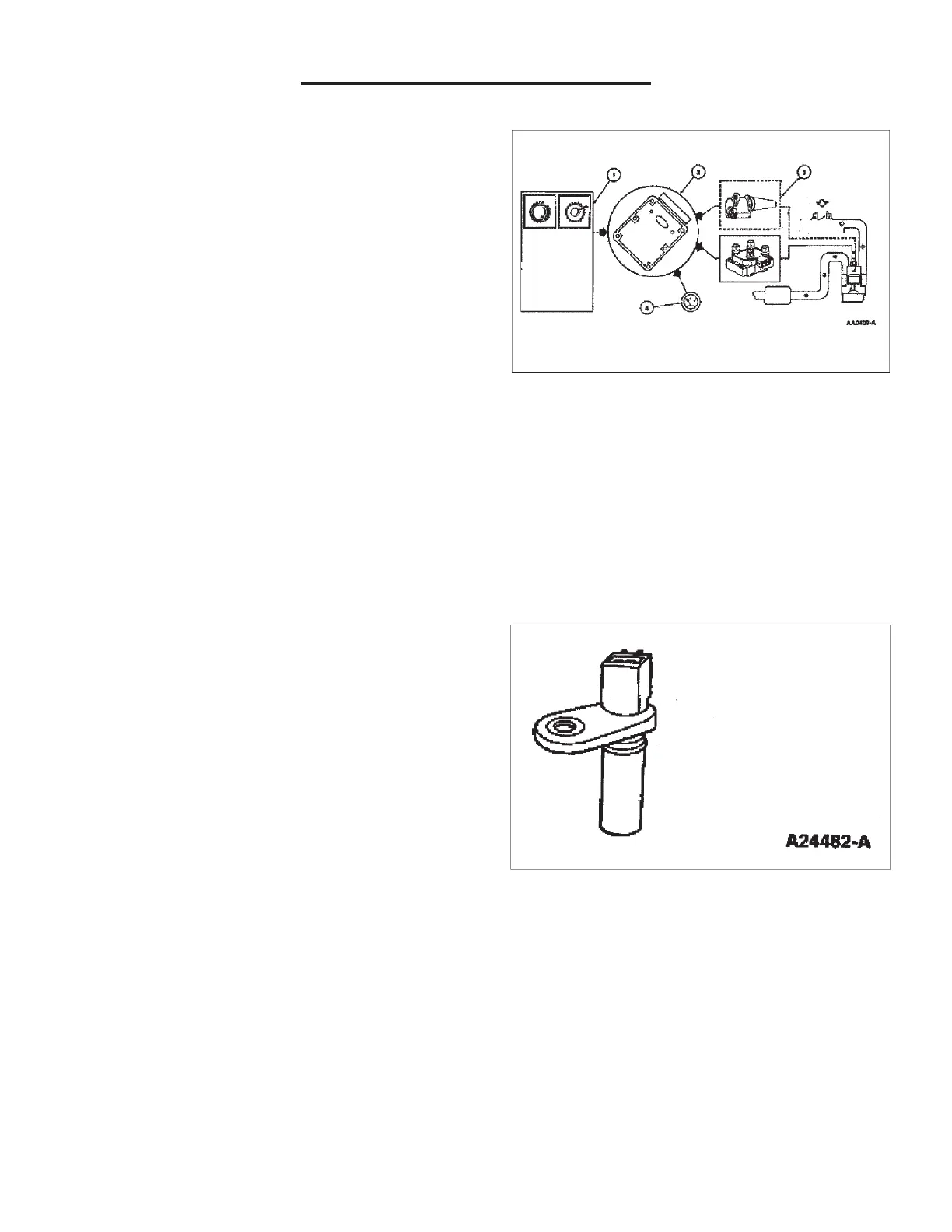

Camshaft Position Sensor

The Camshaft Position (CMP) Sensor detects the

position of the camshaft. The CMP Sensor identifies

when piston #1 is on its compression stroke.

The CMP Sensor is a magnetic transducer mounted on

the engine front cover adjacent to the camshaft. By

monitoring a target on the camshaft sprocket, the CMP

sensor identifies cylinder one to the GCP. The COP EI

system uses this information to synchronize the firing of

the individual coils.

Loading...

Loading...