12

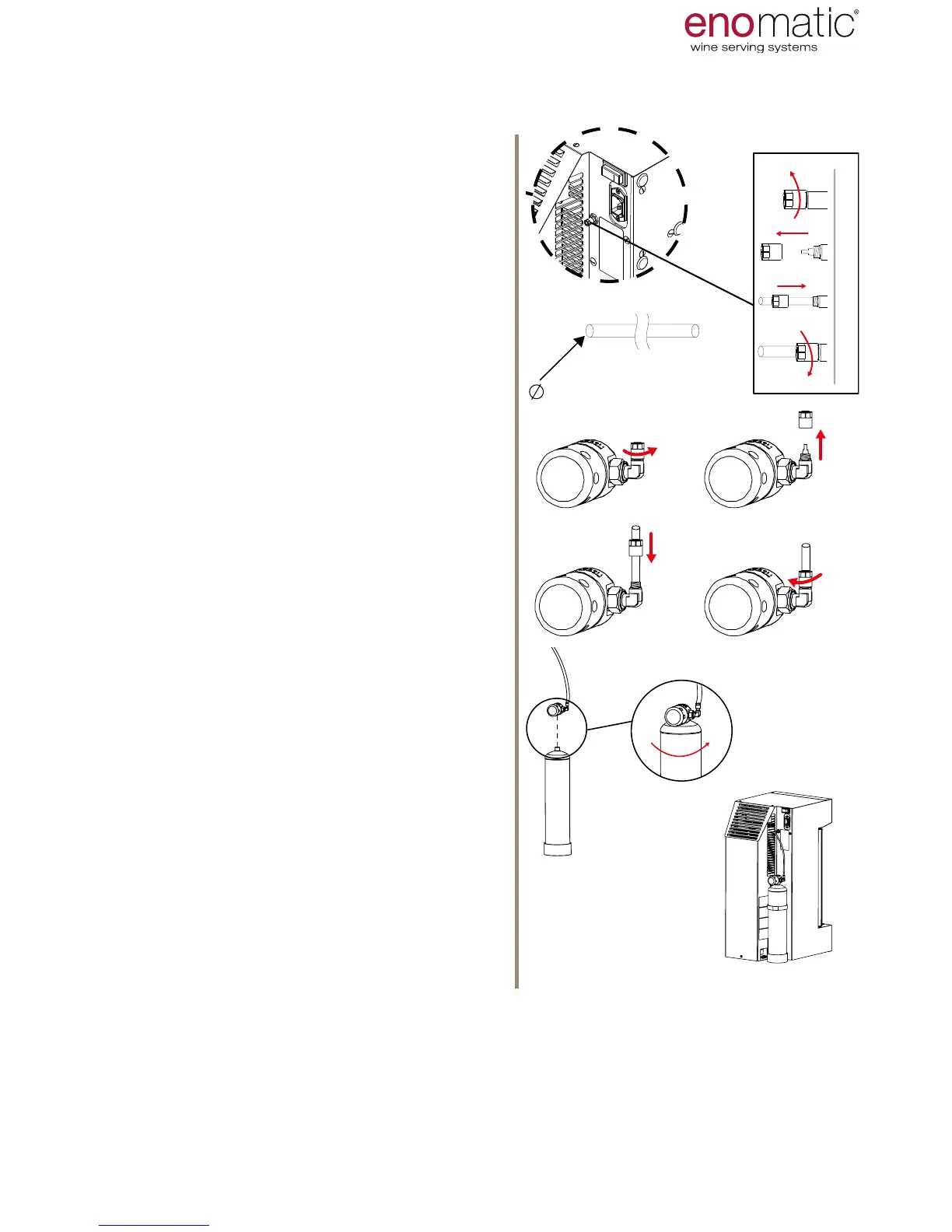

1. Unscrew with your ngers the safety nut

from the tting of inert gas connection (

H

).

2. Remove the safety nut from the tting.

3. Take one end of the gas connection pipe,

insert it within the safety nut and connect

the pipe by pushing it with force as far as

possible on the inert gas connection tting

(H), being careful not to tilt the Dispenser.

4. Tighten the nut to secure the pipe by

squeezing it as much as possible with your

ngers.

5. Take the pressure regulator to the dispos-

able cylinder (gure to the side)

6. Unscrew with your ngers the safety nut

from the cylinder pressure regulator con-

nection tting

.

7. Remove the safety nut.

8. Insert within the safety nut the other end

of the pipe and connect it with force to the

tting, pushing it to the end.

9. Tighten the nut to lock the pipe, squeezing

it as much as possible with your ngers.

10. Place the bottle on the working sur-

face, remove the plastic protective cap

and screw it quickly down to the bottom

of the pressure regulator (rotate the cyl-

inder while holding the regulator still

to prevent the gas connection pipe

from twisting). A small leak during the

screwing stage is in any case envisaged

therefore at this phase accelerate tight-

ening.

11. Open the pressure regulator valve to

minimum 4 Bar and maximum 6 Bar.

12. Place the bottle in the appropriate rear

space of the Dispenser, supporting the

base on the surface and fasten it with the

specic locking strap (E) or place it close

to the Dispenser.

6

8 9

7

INSTALLATION

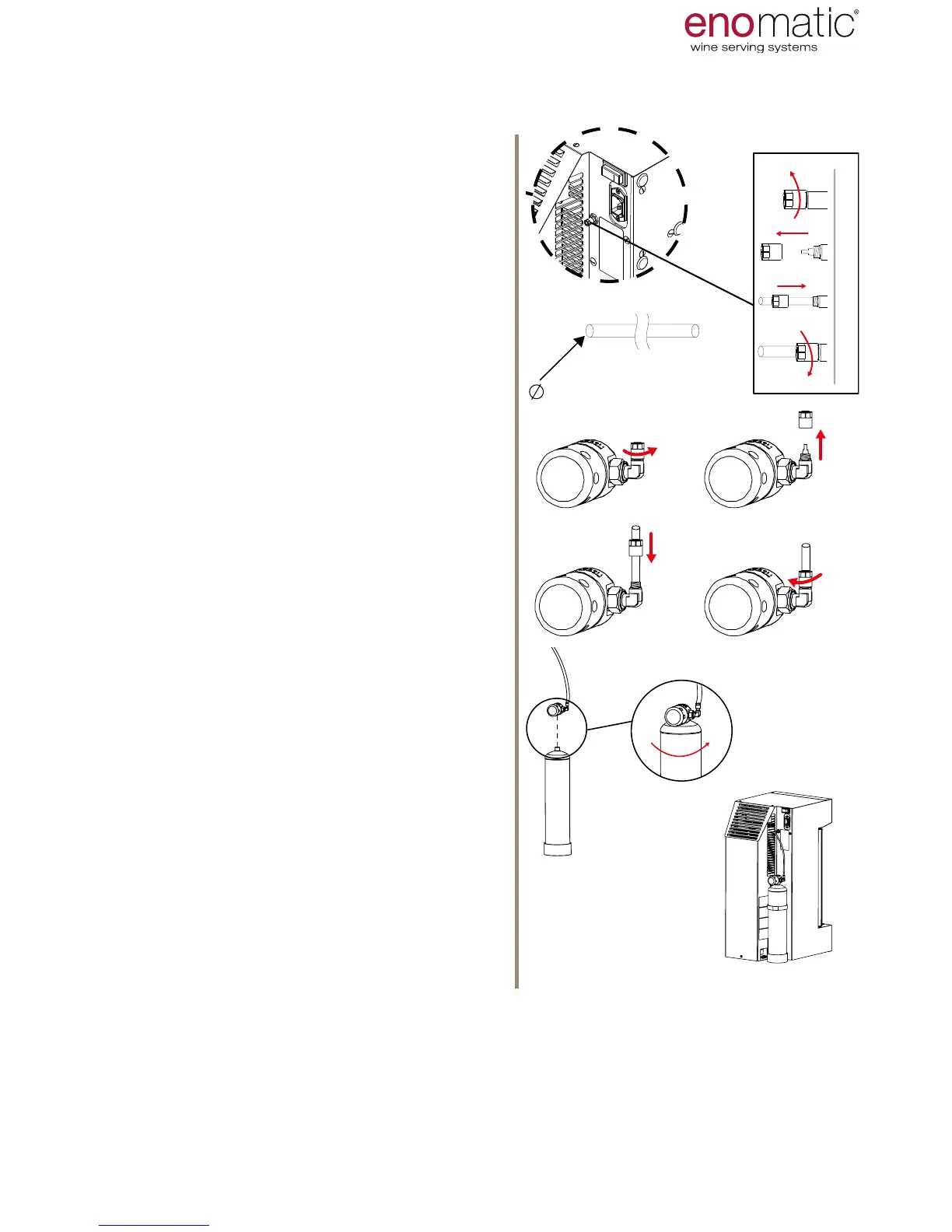

Should it be necessary to disconnect the Dispenser from the gas supply, never

directly extract the pipe from the machine without rst having closed the valve

on the pressure regulator. Close the regulator valve. Only unscrew the cylinder

from the pressure reducer if it is tted with a safety needle valve.

DISPOSABLE PERFORATION CYLINDERS MUST NEVER BE

REMOVED BEFORE THEY ARE COMPLETELY EMPTY

Carefully read all of the safety guidelines of the cylinder (container under pres-

sure) before manipulating it.

Loading...

Loading...