Maintenance 10. Ball Screw Spline Unit

G6 Rev.21 169

10.1 Greasing the Ball Screw Spline Unit

Grease

For Ball Screw Spline Unit (AFB grease)

For wiping grease (Spline shaft)

Cross-point screwdriver 1

For clamp band removal

Only for Cleanroom-model and

The brake release switch is applied to both Joints #3 and #4. When the brake release

switch is pressed, the respective brakes of the Joints #3 and #4 are released simultaneously.

(Joint #4 brake is installed to G6-**3** only.)

Be careful of the shaft falling and rotating while the brake release switch is being pressed

because the shaft may be lowered by the weight of the end effector.

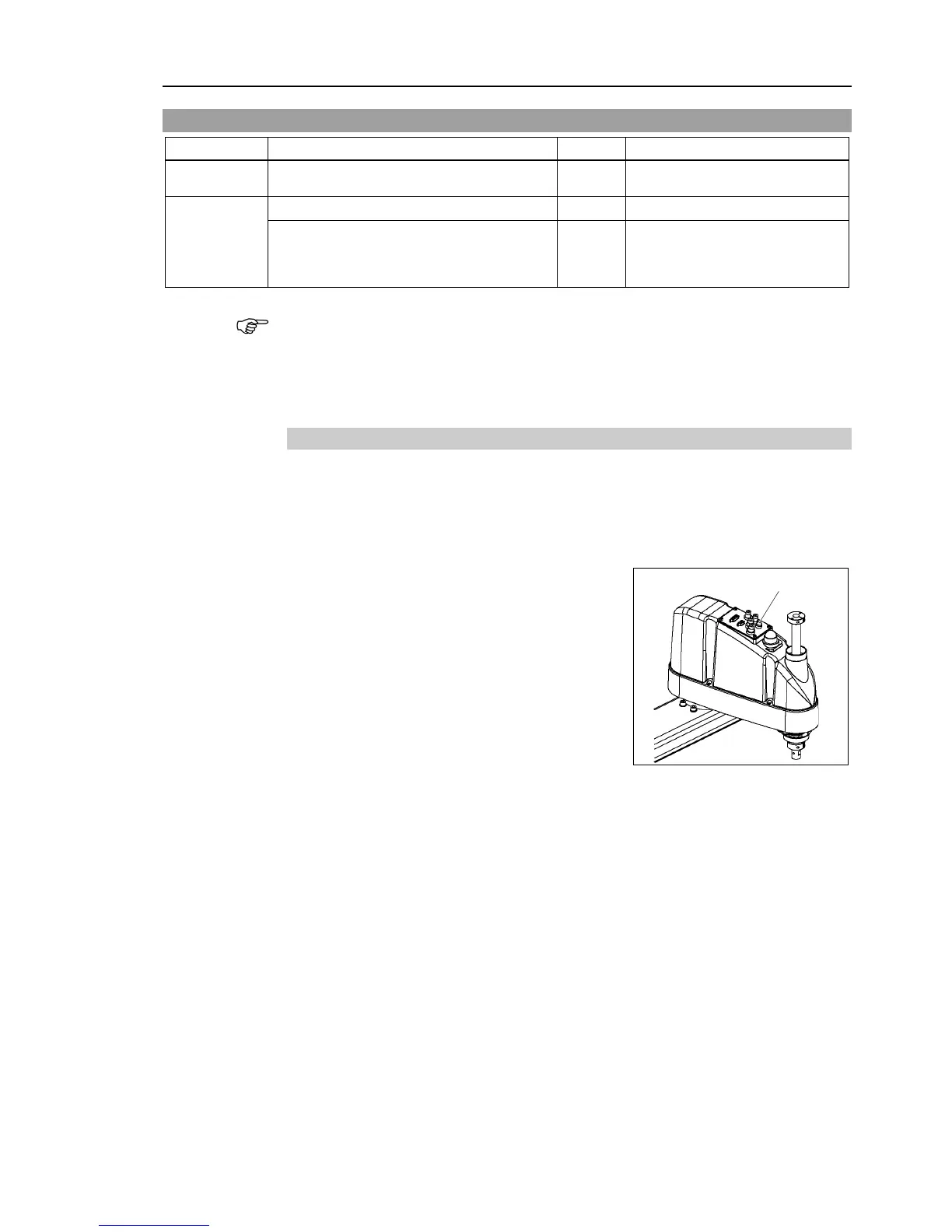

10.1.1 Standard-model (S type)

Cover the surrounding area such as the end effector and peripheral equipment in case the

grease drips.

Controller. Stop motor excitation. (MOTOR OFF)

Move the arm to a position where Joint #3 can be moved in full stroke.

Move the shaft to its upper limit manually while

pressing the brake release switch.

Wipe off the old grease from the upper part of the

shaft, and then apply new grease to it.

applying the new grease to the upper part

of the shaft, directly fill the grooves on it by

hand

. Wipe off excess grease from the shaft.

Move the shaft to its lower limit manually while pressing the brake release

Wipe off the old grease from the lower part of the shaft, and then apply new grease to

it.

When applying the new grease to the lower part of the shaft, directly fill the grooves

on it by hand

. Wipe off excess grease from the shaft.

shaft up and down several times while pressing the brake release switch to

smooth out the grease on the shaft.

Wipe off excess grease from the shaft.

When wiping off the excess grease from the upper part of shaft, turn OFF the

Controller and remove

For details, refer to Maintenance: 3.1 Arm Top Cover.

Loading...

Loading...