EPSON Stylus CX4100/CX4200/CX4700/CX4800/DX4200/DX4800/DX4850 Revision A

ADJUSTMENT Adjustment by Using Adjustment Program 178

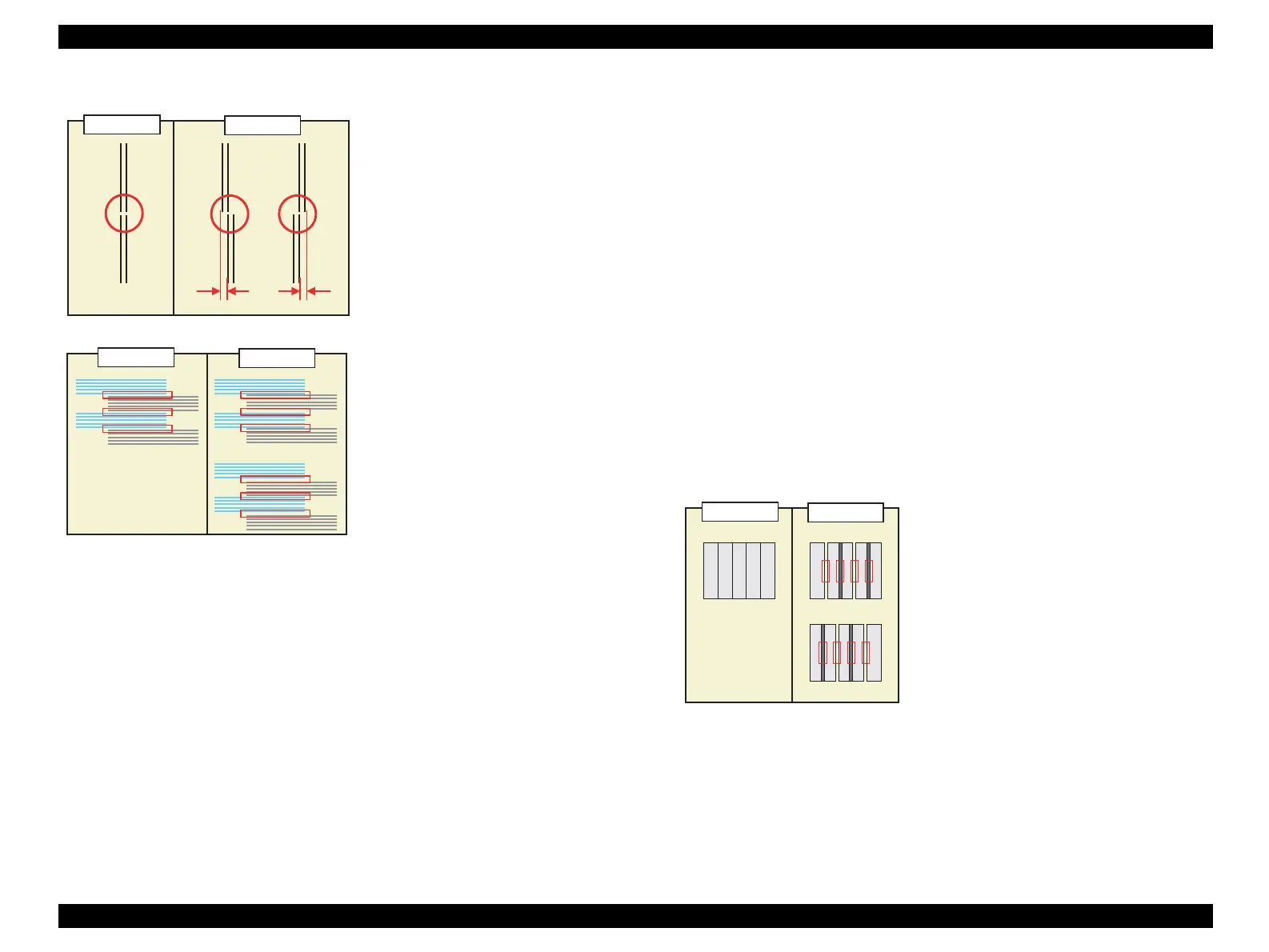

Figure 5-4. Head Angular Adjustment Printing Pattern

5.2.11 Bi-D adjustment

Adjustment procedure

1. Set Normal Paper A4/Letter on the Paper Support.

2. Select “Bi-D adjustment” in the Adjustment Program.

3. Click the [Print] button to print the Bi-D adjustment pattern.

4. Check the printed patterns and select a pattern number that has the least

amount of misalignment in each of the VSD dots.

5. Click the [Input] button to write the adjustment value of checked items.

6. Print the check pattern again, and check the adjustment result.

[Treatment procedure for NG product]

1. Replace the Print Head with new one again.

2. Print the check pattern, and check the adjustment result.

3. If the result is NG level, confirm the installation condition of removed parts

during disassembly.

4. Perform Step 2 again.

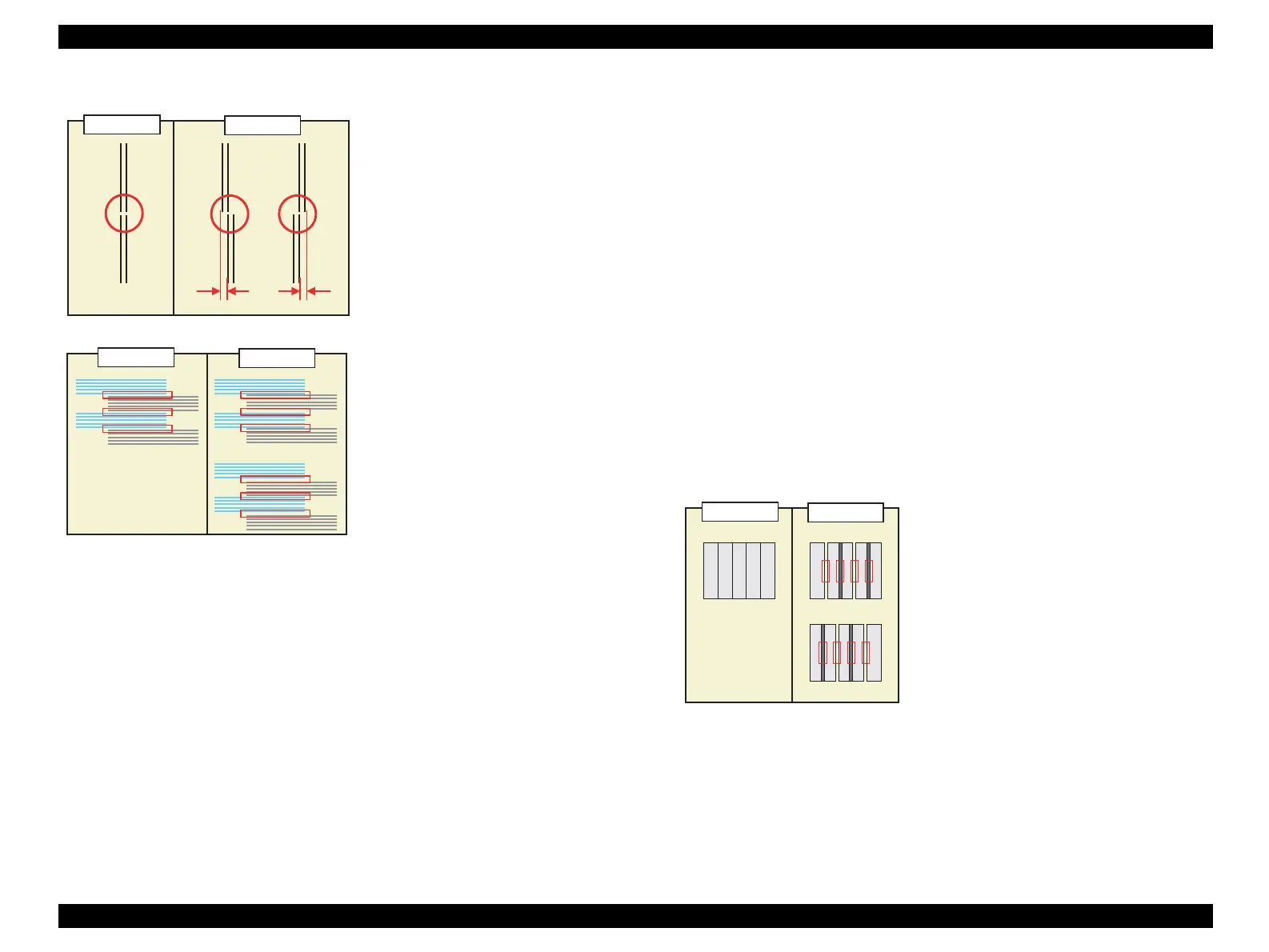

Figure 5-5. Bi-D Adjustment Printing Pattern

OK pattern

NG pattern

OK pattern

NG pattern

Band pattern

Raster offset pattern

[Judging Standard]

The printed line should be straight line.

[Reference]

Shift length of Head Angular pattern is MAX

±50µm

[Judging Standard]

Spaces between the cyan lines and gray lines

should be uniformed.

[Reference: Standard value in manufactory]

±70µm

OK pattern

NG pattern

[Judging Standard]

The block patterns should align without gap and

overlapping.

[Reference]

GAP Bi-D for each Dot

• VSD1 BLACK, COLOR: 60

µm

• VSD3 BLACK, COLOR: 40

µm

Loading...

Loading...