ESTUN AUTOMATION Proprietary

Appendix A Glossary

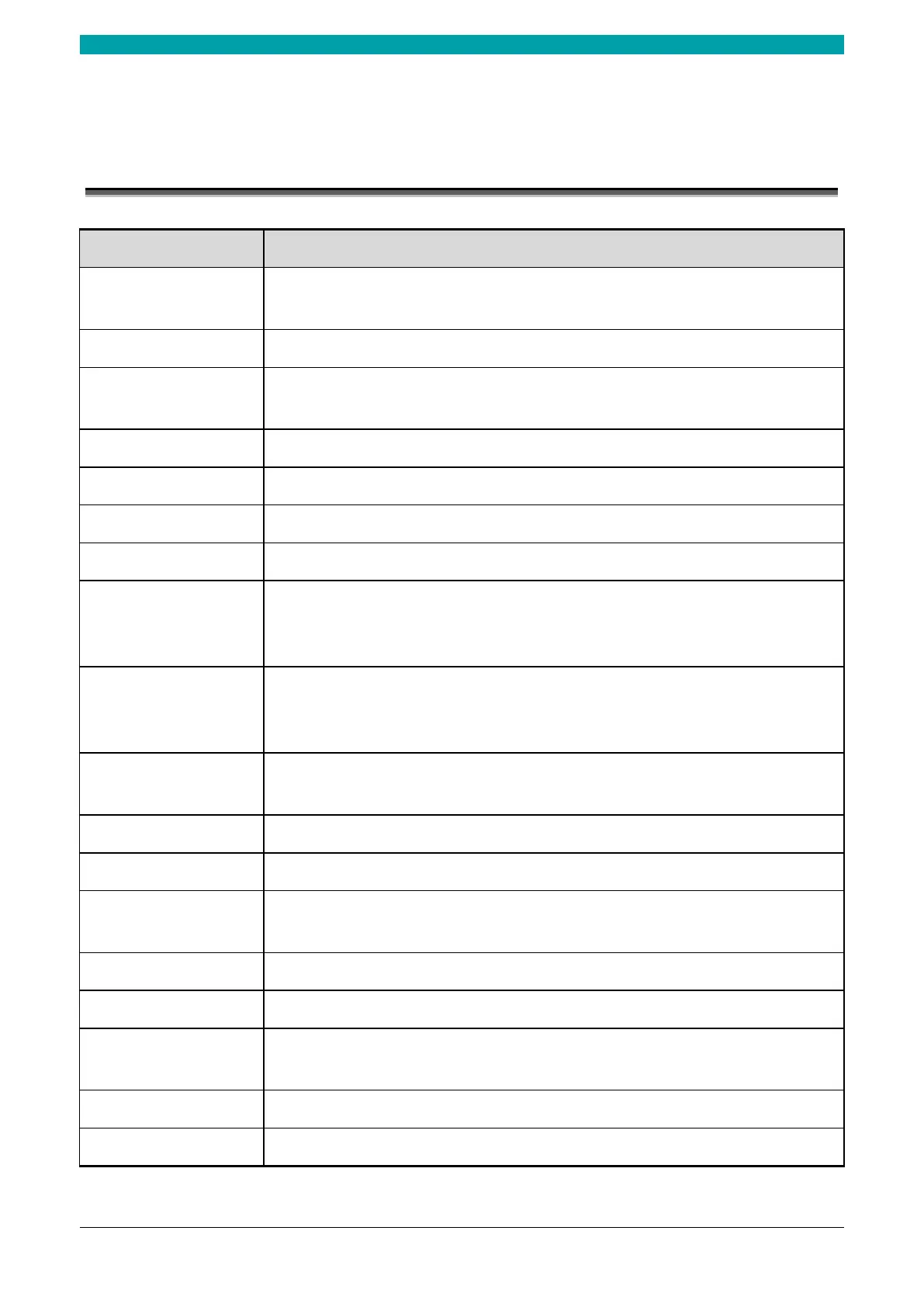

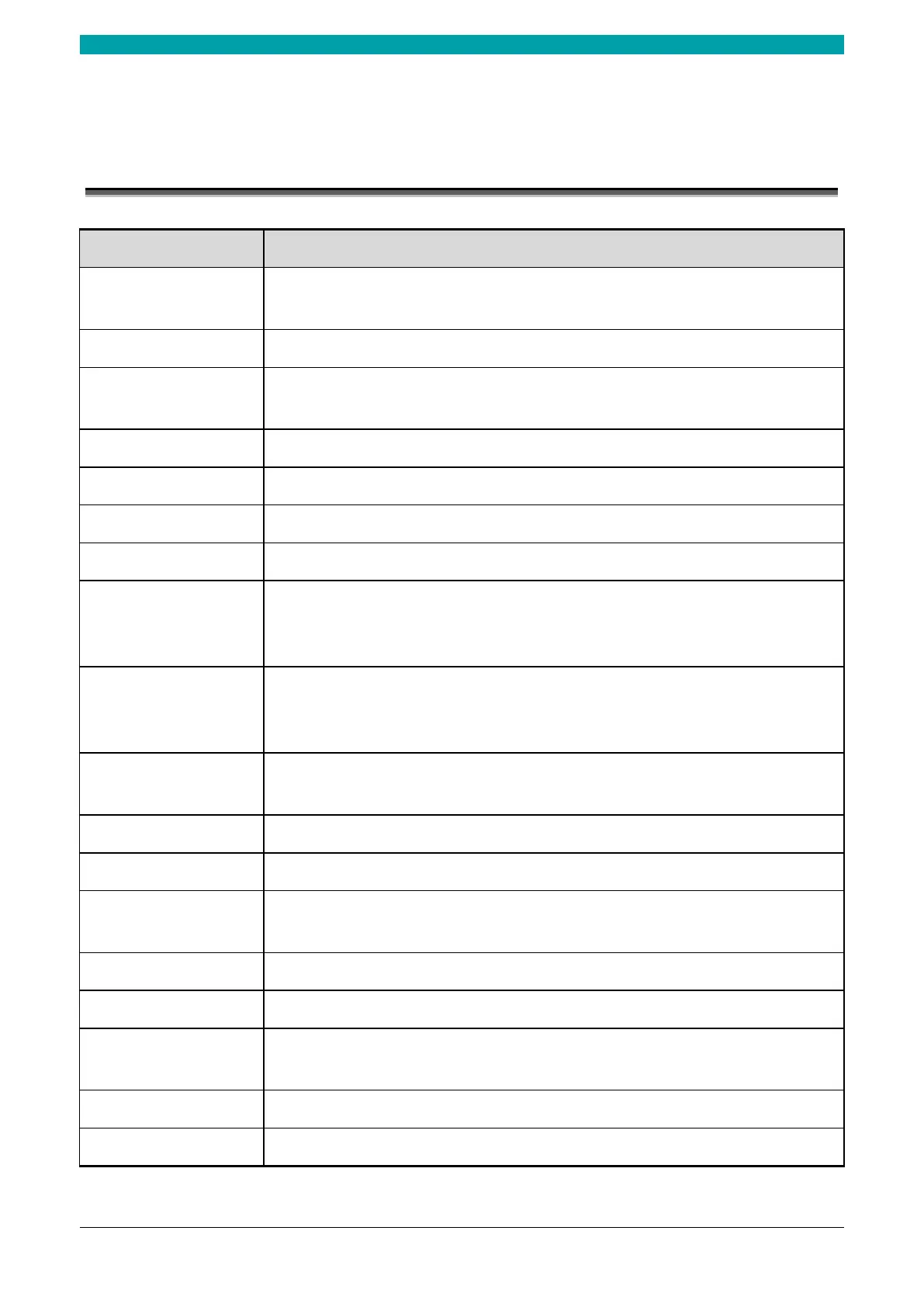

Glossary Description

Axis

A reference direction, which can make the parts of the machine do the linear motion or rotation

motion.

Machine Coordinate System Cartesian coordinate system based on machine zero, which is fixed on the machine.

Computerized Numerical

Control, CNC

Fulfill the numerical control the processing functions by the computer.

Reference Position A fixed point along the axis, which can be referenced to the origin of the machine.

Hardware Limit A limit position, which is mounted in the machine, can limit the movement of the parts.

Software Limit A limit range, which is programmed in the device, can limit the movement of the parts.

Mute A position where the process switches from Fast-Closing to Pressing.

DA (Digital to Analog)

To convert the Digital signal into the Analog signal. In general, decode the digital signal and convert

into a corresponding level, which can form a step shape signal, and then perform a low-pass

filtering.

AD (Analog to Digital)

To convert the Analog signal into the Digital signal. The analog signal is subjected to a line filter,

and then samples the hold circuit to be a step shape signal, and then the step shape signal is

converted into a binary code by the encoder, that is, the desired digital signal.

Upper Dead Point, UDP

The critical position for the movement of the beam, where the beam cannot continue to move

upwards.

Punch Also known as male mold, which is a die part forming the shape of the end face.

Die Also known as female mold, which is a die part forming the shape of the outer.

Lower Dead Point, LDP

The critical position for the movement of the beam, where the beam cannot continue to move

downwards. The theoretical position is at the lowest point of the V-Opening.

Fast Closing One process of the bending step, which can make the beam moves to Mute fast.

Pressing One process of the bending step, which can make the beam moves from Mute to bending point.

Dwell

In order to ensure the formation of the workpiece, it is necessary to keep the pressure for a period of

time when the punch has been reached the bending point, against the tensile strength of the material.

Decompression One process of the bending step, which can remove the pressure from the sheet.

Opening One process of the bending step, which can make the beam moves towards the UDP.

Loading...

Loading...