PVDF PTFE TFE/P

CERAMIC

TFE/P

PVDF PE / PVC PP

INSTALLATION

Introduction

This section describes the steps for installing the pump, the pipes, and the electrical wiring. Read these

instructions carefully before beginning any activity.

Follow these guidelines when installing the pump.

• Ensure that the pump and all related equipment is turned off before starting work.

• If you encounter abnormalities or warning signals, stop immediately. Only start work again when you are

absolutely sure that you have removed the cause of the problem.

• Do not install the pump in hazardous locations or in areas at risk of fire or explosion.

• Avoid electrical hazards and fluid leakage. Never use a damaged or defective pump.

Pump installation

Install the pump away from heat sources and in a dry place at a maximum ambient temperature of 40 ° C. The

minimum temperature, not lower however than 0 ° C, depends on the type of liquid to be metered, which must always

remain in a liquid state. To fasten the pump use the supplied screw anchors, or those most suited to the support type

chosen.

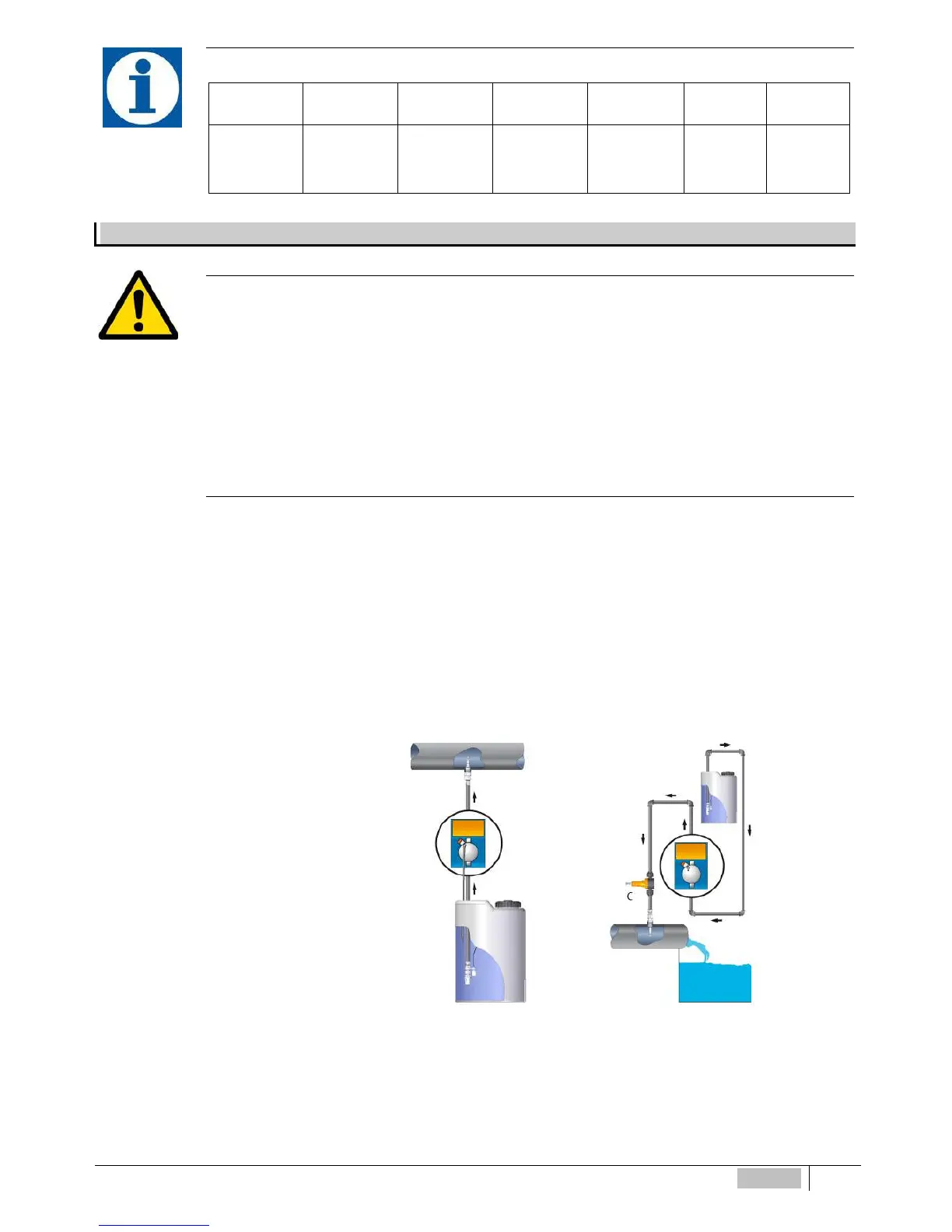

The pump can be installed either above or below the liquid level in the tank. Usually in the case of installation above

the tank, limit the suction height to within 1.5 metres of the liquid level. (see fig. 2a). For liquids that generate aggressive

vapours, do not install the pump into direct contact with the fumes and adopt the necessary precautions to prevent early

deterioration of the equipment.

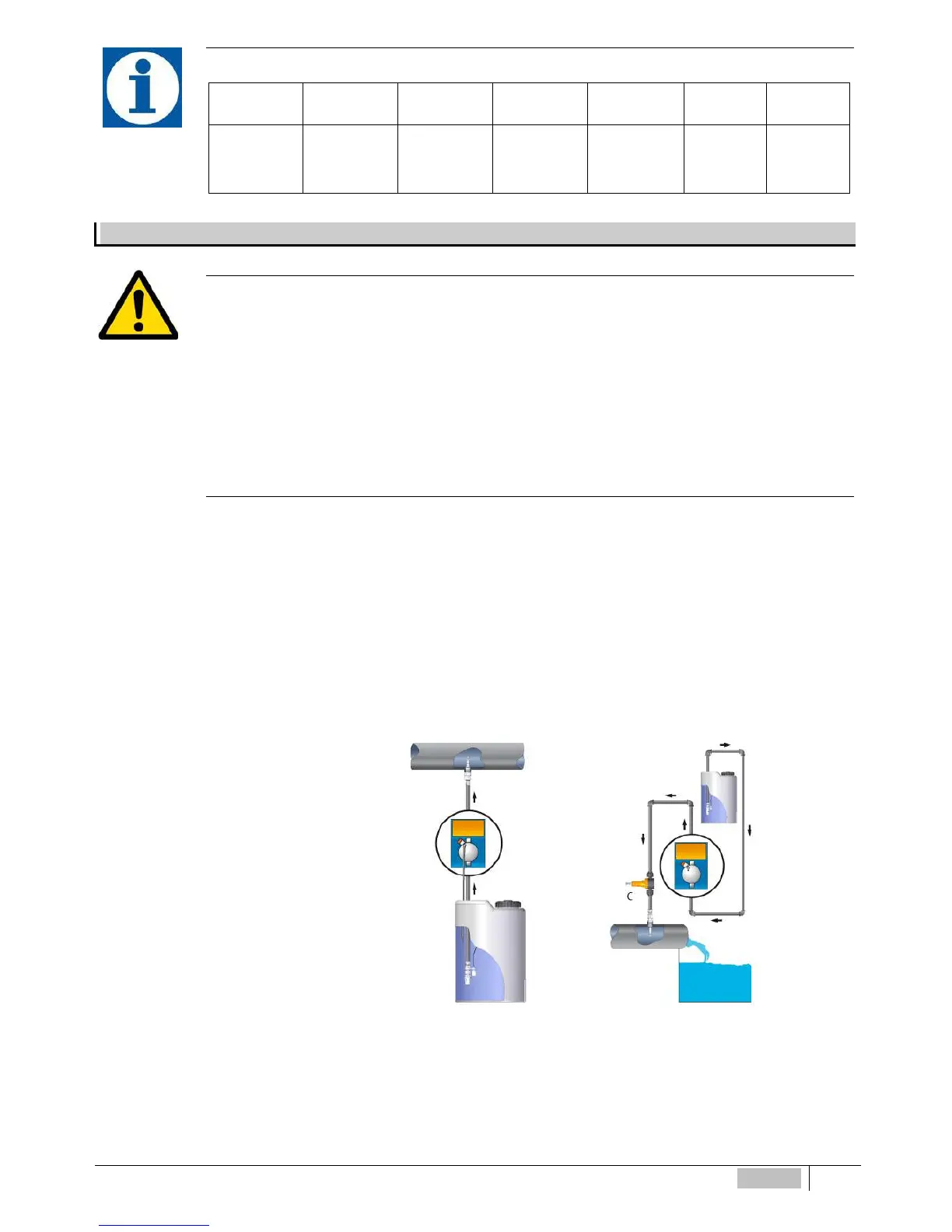

In the case of installation below, i.e. with the pump positioned below the liquid level of the tank (Fig. 2b), siphoning

may occur. Periodically check the functionality of the injection valve, as excessive wear may lead to the additive

falling into the plant even with the pump turned off. If the problem persists, fit a back pressure valve C suitably

calibrated between the metering pump and the injection point as shown in Fig. 2b

Fig. 2a Fig. 2b

Loading...

Loading...