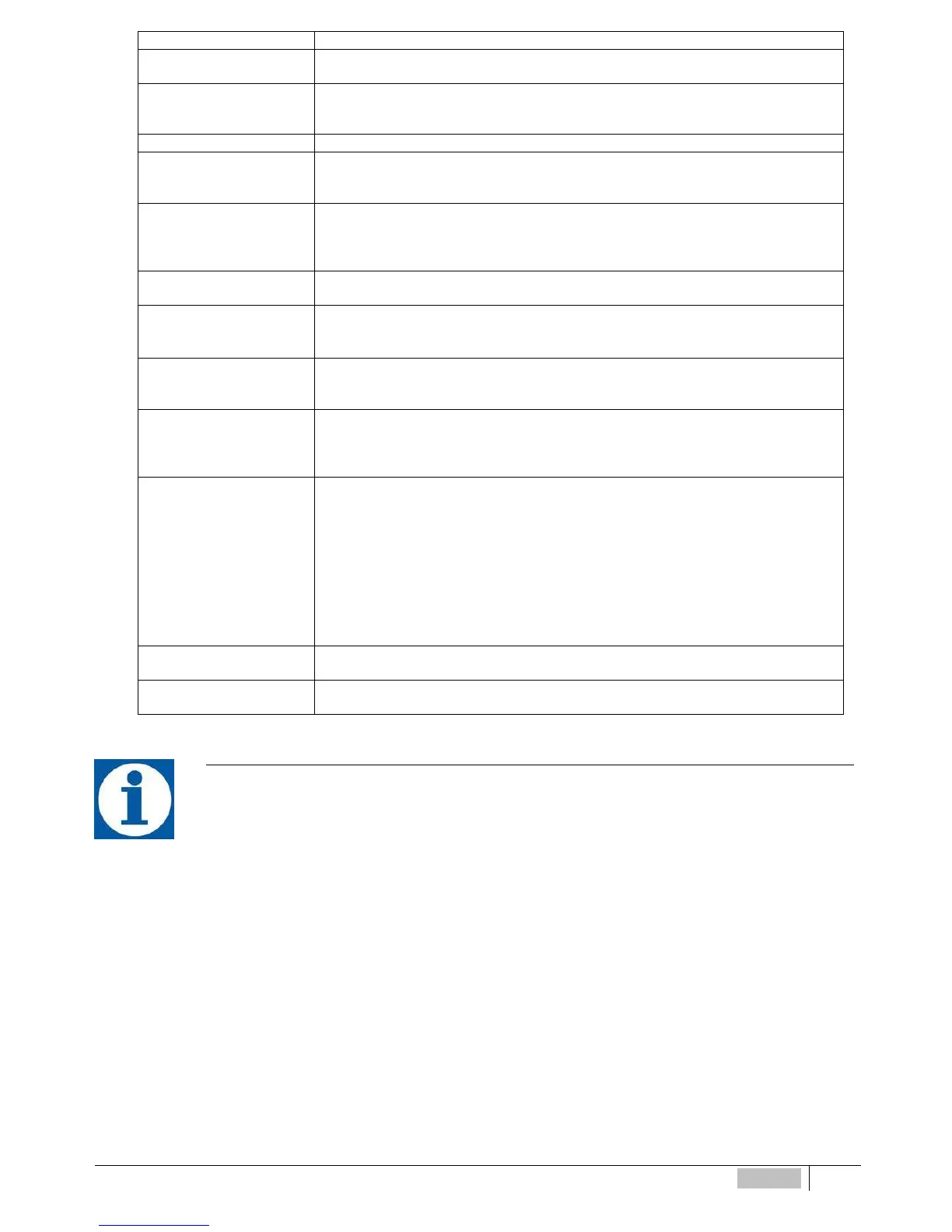

transmit pulses to the magnet

Display switched off, no LEDs

switched on

Check that the pump is powered correctly (socket and plug): if the pump remains inactive, please

contact our Service Centres.

Display switched on, the pump

is not running.

Check that the programming is correct, or press the START/STOP button; if the problem persists,

check that the external stop is not activated or if the pump is in stand-by due to the intervention of

The pump runs irregularly

Check that the value of the power supply voltage is within the specified limits.

If there is no additive the pump

Check the connection between the level probe and the relative connector

The pump does not run in the

functions: 1xN, 1xN(M), 1:N,

ppm, mL/imp. , L/imp. , mL/m

3

Check the connection between the meter output and the corresponding connector on the pump,

check that the display receives the pulse from the meter (indicated with a dot lighting up on the

left side of the display)

The pump does not run in the

mA function

Check the connection between the output of the instrument with the mA output and the pump

input. Check that the polarity is correct.

conditions when operating with

• Check the connection between the output of the flow switch and the corresponding

• Make sure that the pump is actually injecting liquid and not air.

switched on it beats two or

three times and then blocks

Check the settings of the Level and Flow Sensor menu (if featured in the pump menu)

The probe (pH, Rx, Cl) reading

does not correspond to the

value detected with other

Clean the probes. Check the state of ageing of the probe. Try and recalibrate the probe.

There is an infiltration

Undo the four head screws and make sure that the o-ring of the pump body is in good condition

and that the diaphragm is screwed on correctly, otherwise replace them. Also make sure that the

infiltration did not damage the board or the magnet.

Through the control panel

Observe the board and check the state of preservation of the electrical components and printed

circuit tracks. Check the electrical resistance of the electromagnet.

In the event that one of the two components is damaged, replace it. Make sure that all the

components that secure the flow pipe are mounted properly and that they are not damaged.

Replace also serigraphy which enabled the infiltration.

The pump runs but does not

draw the liquid

Remove the suction and discharge valves, clean them and replace them in the same position.

Check the state of clogging of the filter and the injection valve

If certain issues cannot be solved, try to reset the pump, to restore all the factory settings (see

RESET chapter)

Warranty

2 years (excluding parts subject to normal wear i.e.: valves, fittings, tube fixing clamps, tubes, seals, filter and

injection valve). Improper use of the equipment invalidates the warranty. The warranty is intended to be Ex Works or

authorized distributors.

Loading...

Loading...