CNC 8035

·14·

Version history (M)

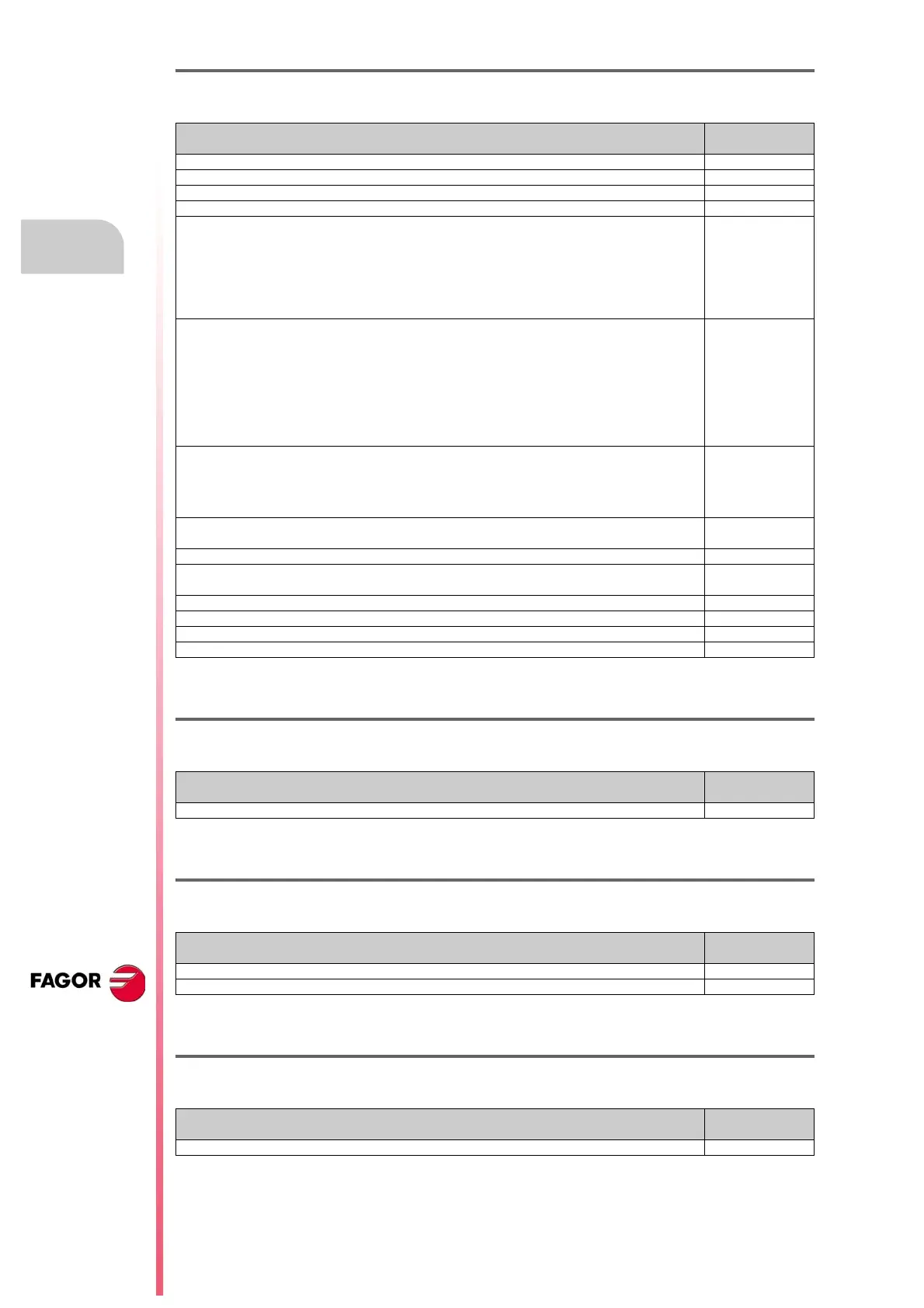

Software V09.1x December 2004

Software V9.12 February 2005

Software V09.13 April 2005

Software V09.15 June 2005

List of features Manual

Calculation of central unit heat dissipation . INST

New board "Axes2". INST

Automatic keyboard type identification. INST

Frequency filters for axes and spindles. INST

Machine parameters.

COMPMODE (P175). New tool radius compensation methods.

Axis parameters that may be modified from OEM subroutine/program: REFVALUE, REFDIREC,

FLIMIT.

Spindle parameters that may be modified from OEM subroutine/program: REFVALUE,

REFDIREC, SLIMIT.

INST

Variables.

DNCSTA: DNC communication status.

TIMEG: Status of the timer count programmed with G4

HANDSE: Handwheel's axis selector button pressed.

ANAI(n): Value of the analog inputs.

APOS(X-C): Real coordinates of the tool base, referred to part zero.

ATPOS(X-C): Theoretical coordinates of the tool base, referred to part zero.

INST / PRG

Retracing function.

If RETRACAC=2 , the retrace function does not stop at the M functions.

The RETRACAC parameter is initialized with [SHIFT][RESET].

The number of blocks being retraced has been increased to 75.

INST

When activating tool radius compensation in the first motion block even if there is no movement

of the plane axes.

INST

Manual intervention with additive handwheel. INST / OPT

G46. Maintain G46 when the home search does not involve any axis of the angular

transformation.

INST / PRG

MEXEC. Execute a modal part-program. PRG

Up to 319 G functions now available. PRG

The simulations without axis movement ignore the G4. OPT

Maintain the feedrate selected in simulation. OPT

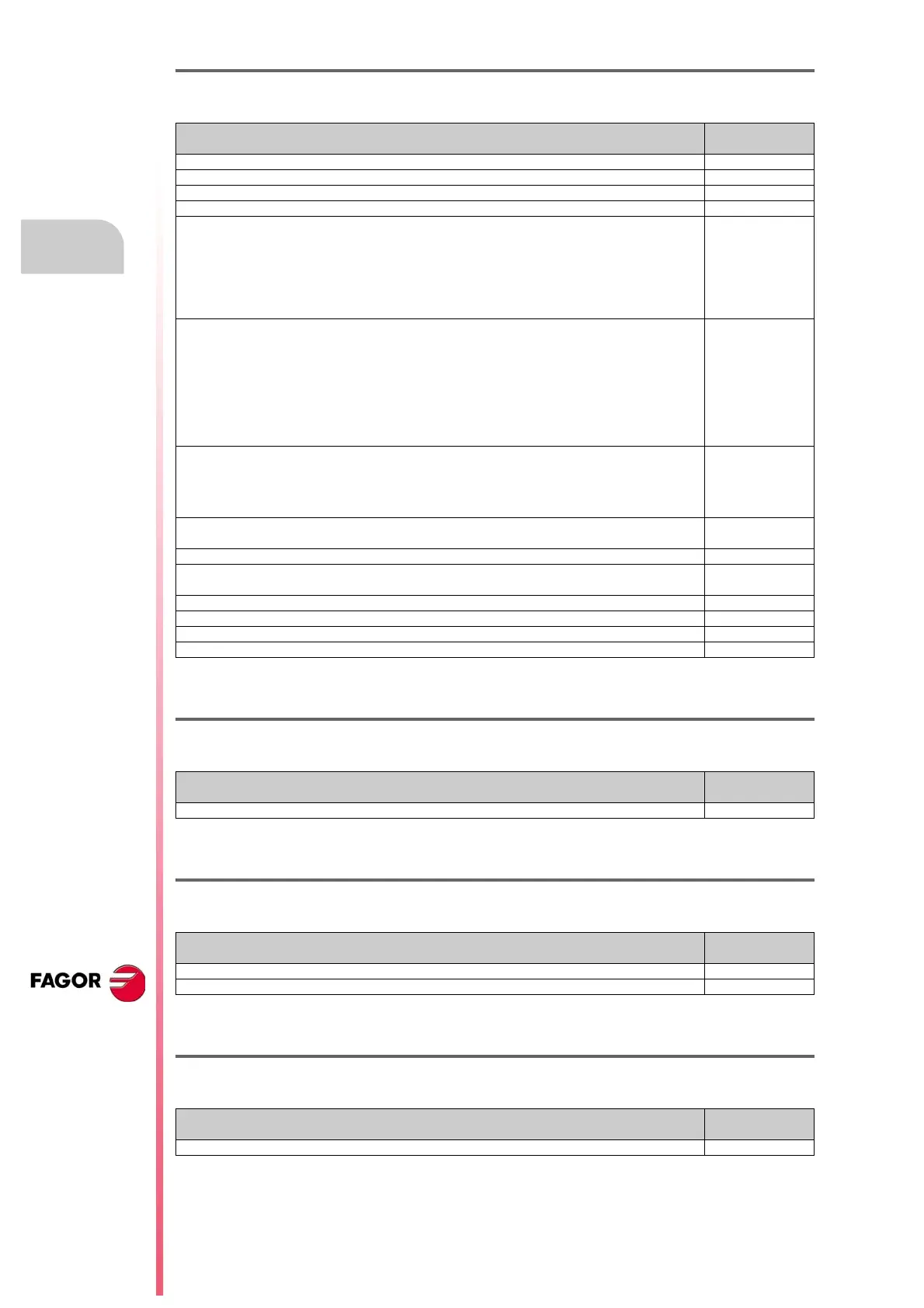

List of features

Manual

Look-ahead INST / PRG

List of features

Manual

Hirth axis pitch may be set in degrees via parameters. INST

Rollover positioning axis. Movement in G53 via the shortest way. INST

List of features

Manual

CAN servo system. INST

Loading...

Loading...