Installation manual

CNC 8035

MACHINE PARAMETERS

Tables

4.

(SOFT M: V15.3X)

(S

OFT T: V16.3X)

·175·

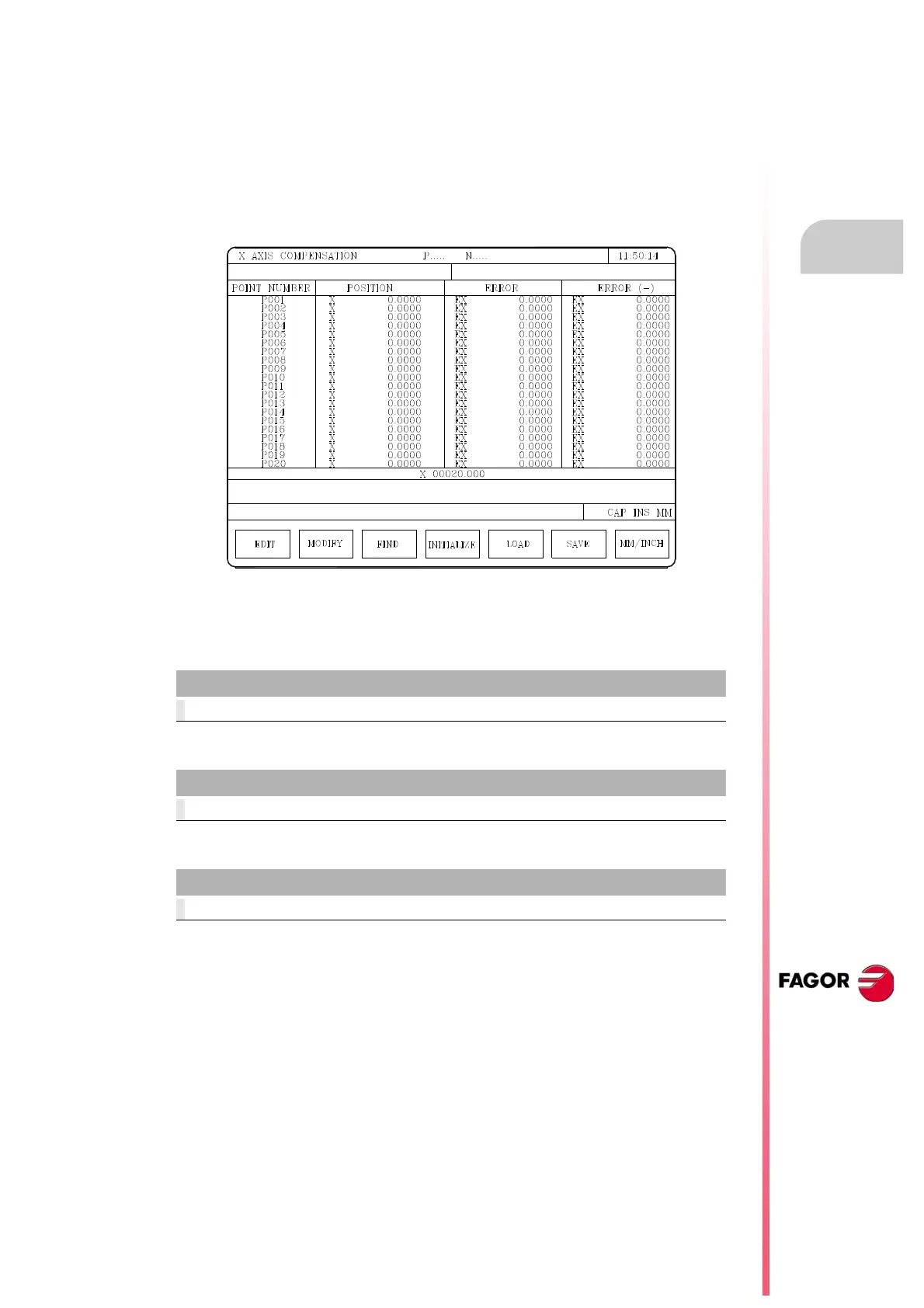

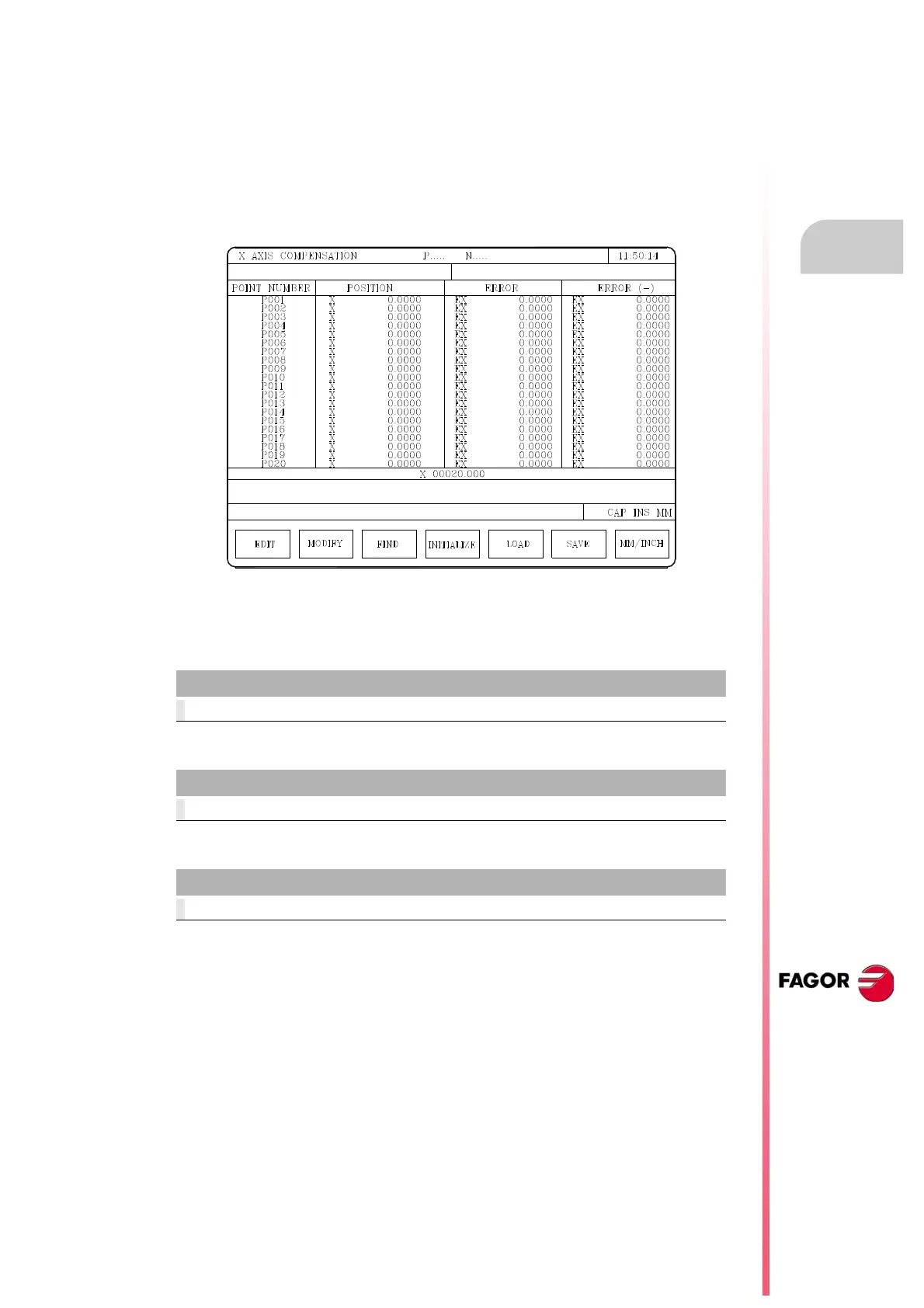

4.9.2 Leadscrew error compensation table

The CNC provides a table for each one of the axes requiring leadscrew compensation. The CNC

will provide a table for each one of the axes having leadscrew compensation. This type of

compensation is selected by setting a.m.p. LSCRWCOM (P15).

The number of elements of the table must be set by a.m.p. NPOINTS (P16), being possible to define

up to 255 points per axis. Different compensation values may be defined at each point for each

moving direction.

Each parameter of the table represents a point of the profile to compensate. The following

information is defined at each point:

• The position occupied by the point in the profile (position to compensate). This position is defined

by its coordinate referred to machine reference zero.

• The error of the leadscrew at that point, when moving in the positive direction.

• The error of the leadscrew at that point, when moving in the negative direction.

For each axis position, define the amount of error to be compensated in both directions. If the amount

of error in the negative direction is zero in all points, it assumes that the amount of error defined

for the positive direction is valid for both directions.

Leadscrew error compensation on rotary axes

On rotary axes, although the display is limited between 0 and 360º, the internal count is

accumulative. When using leadscrew error compensation, set positions 0° and 360°, first and last

point of the table, with the same amount of error. This way, the CNC will apply the same

compensation in all the revolutions.

Otherwise, the compensation will be limited to the indicated field.

Possible values

Within ±99999.9999 mm or ±3937.00787 inches.

Possible values

Within ±99999.9999 mm or ±3937.00787 inches.

Possible values

Within ±99999.9999 mm or ±3937.00787 inches.

Loading...

Loading...