FS10 Series

46 Fluid Components International LLC

6 SAFETY INSTRUMENTED SYSTEMS REQUIREMENTS (SIS)

The safety-critical output of the FS10 is provided through the 4-20 mA signal representing flow and the SPDT relay or solid state output.

Compliance through FMEDA (Failure Modes, Effects and Diagnostic Analysis)

SIL (Safety Integrity Level): 2 – as a single device

HFT (Hardware Fault Tolerance): 0

Subsystem Type: B

FS10 Safety Identification

Firmware version 4.02 or greater

To identify firmware version, use Fluid Components Intl PC Interface program

Installation in SIS Applications

Installations are to be performed by qualified personnel. No special installation is required in addition to the standard installation practices

outlined in this document. Environmental and operational limits are available on page 3, Technical Specifications.

The supplied power should be designed so the terminal voltage does not drop below 21.5 VDC. With the relay output option, current must be

limited to 60% of the relay rating (600 mA) and provide transient voltage protection (refer to page 9 for inductive loads).

Use the PC Interface tool to communicate with and verify configuration of the FS10. Use the keypad lockout function within the PC interface

application to prevent accidental or deliberate change of configuration data during normal operation. Note: Firmware version 4.08 or greater

faults if either button inadvertently locks in to closed (active) position for greater than 30 seconds.

Note:

Transmitter output is not safety-rated during configuration changes. Alternative means should be used to ensure process

safety during transmitter configuration and maintenance activities.

Alarm Levels

Namur: <3.6mA = Fault or >21mA = Fault

Proof Test

The suggested proof test described below detects 95% of possible DU failures in the FS10 Flow Switch. The suggested proof test in

combination with automatic diagnostics detects 99% of possible DU failures in the FS10 Flow Swtich.

The suggested proof test consists of setting the output to the min and max, and a calibration check.

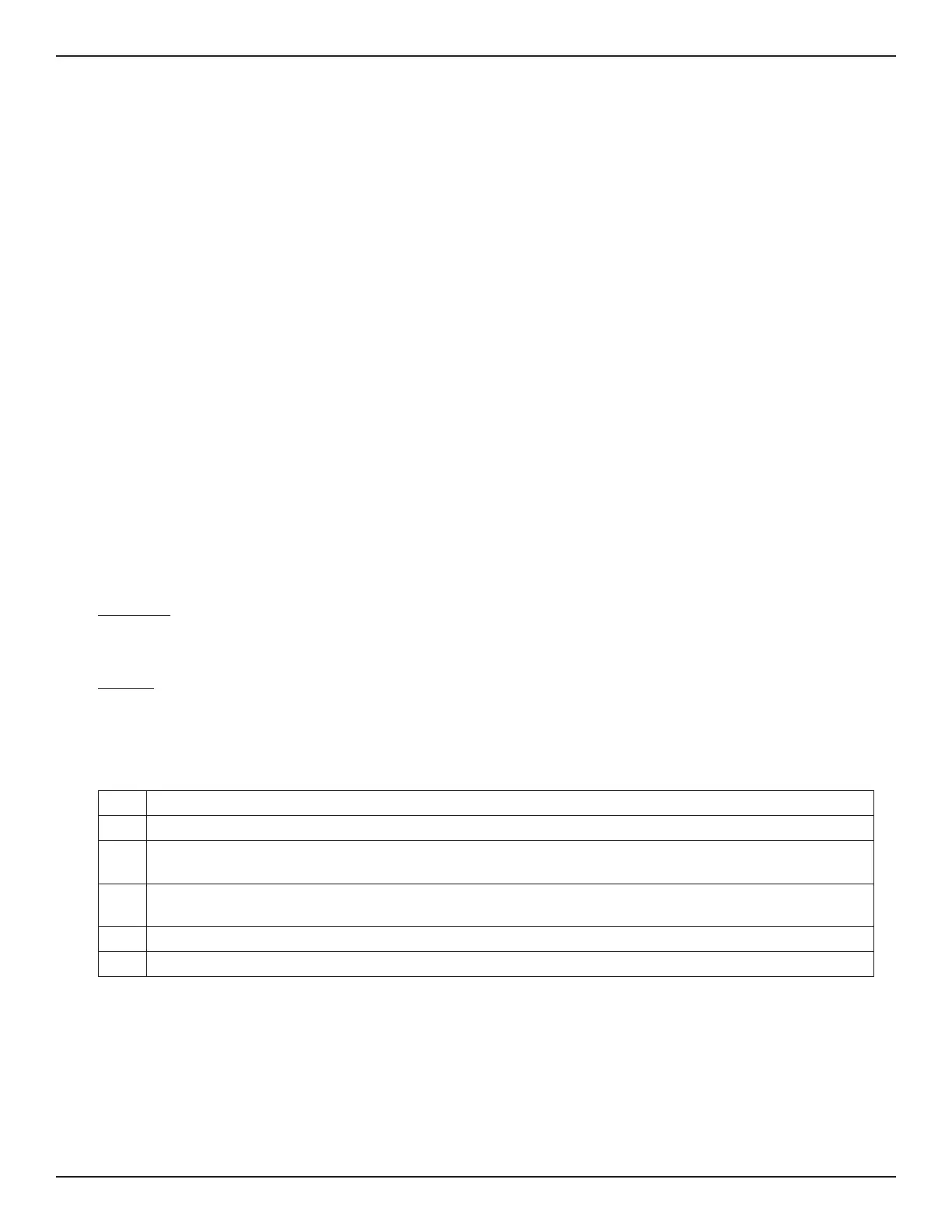

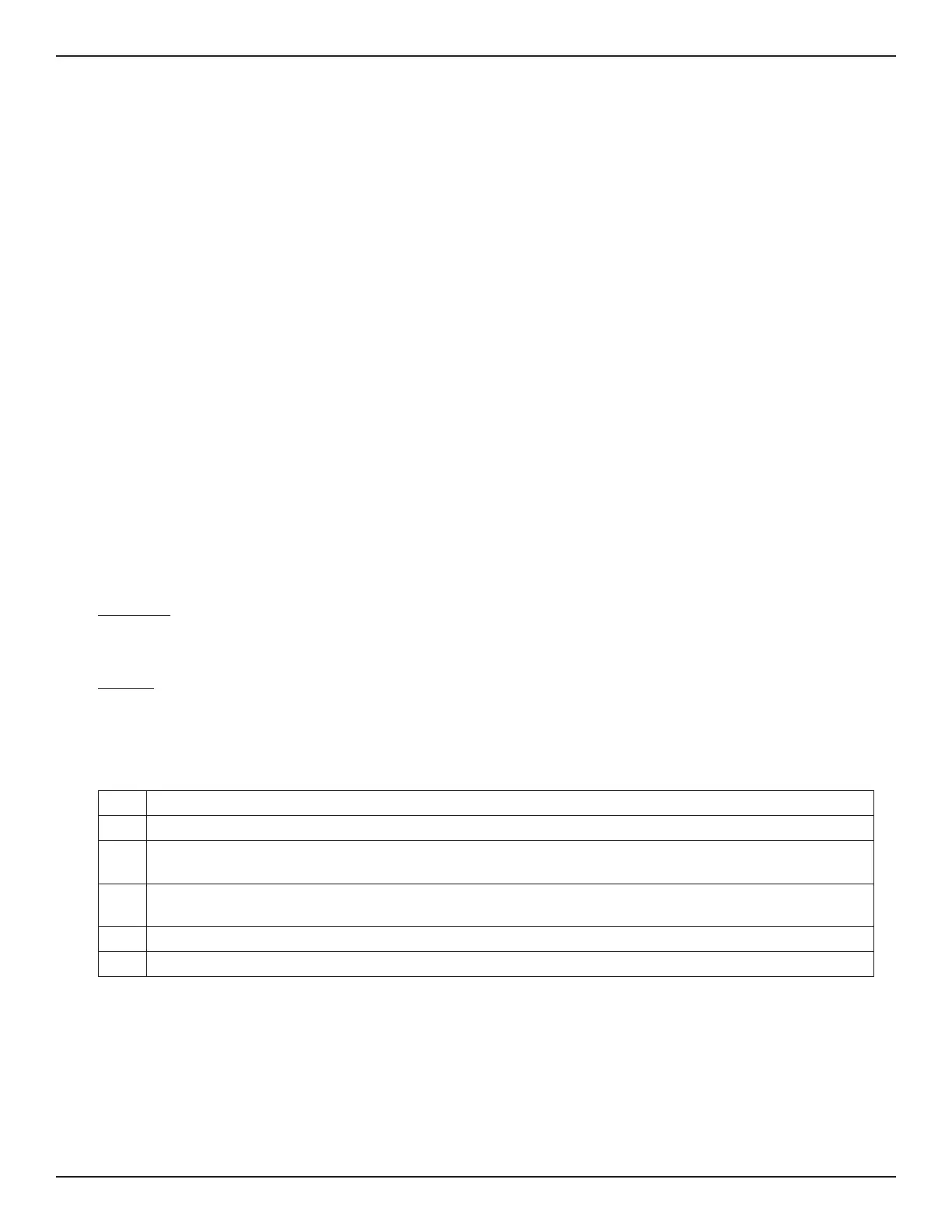

Suggested Proof Test

Step Action

1 Bypass the safety function and take appropriate action to avoid a false trip.

2 Send a command through PC interface or function buttons to the FS10 to de-energize the relay or transistor or go to the high

alarm current output. Verify that the relay or transistor changes state or that the analog current reaches that value.

3 If the current output is used as the safety critical output, send a command through PC interface or function buttons to the

FS10A to go to the low alarm current output and verify that the analog current reaches that value.

4 Perform a two-point calibration of the transmitter over the full working range.

5 Remove the bypass and otherwise restore normal operation.

Product Repair

The FS10 is repairable by major component replacement. All product repair and part replacement is limited to qualified personnel only.

FS10 SIS Reference

The FS10 must be operated in accordance to the functional and performance specifications provided on page 1, Technical Specifications.

Loading...

Loading...