Trouble Shooting

© Festo Didactic GmbH & Co. • MPS 165

Instructor: Please work out step-by-step the difference of Commissioning- and

Maintenance Errors and work out the example together with the participants.

In the following you will find 14 examples of possible error locations in the table.

Advice: For isolation of wire endings you can use a thin shrink tube slipped on the

wire ending and heated up. This tube provides good isolation.

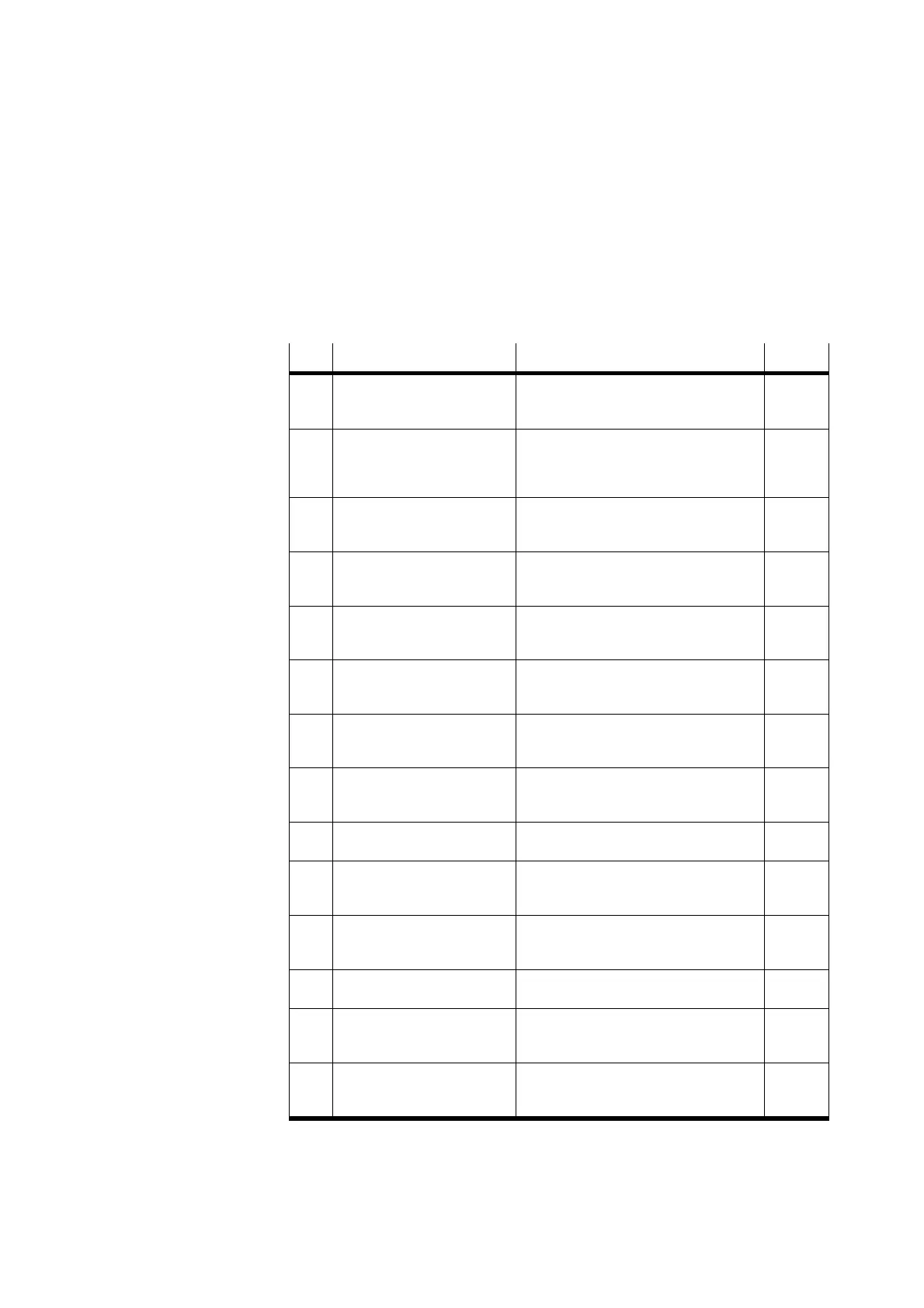

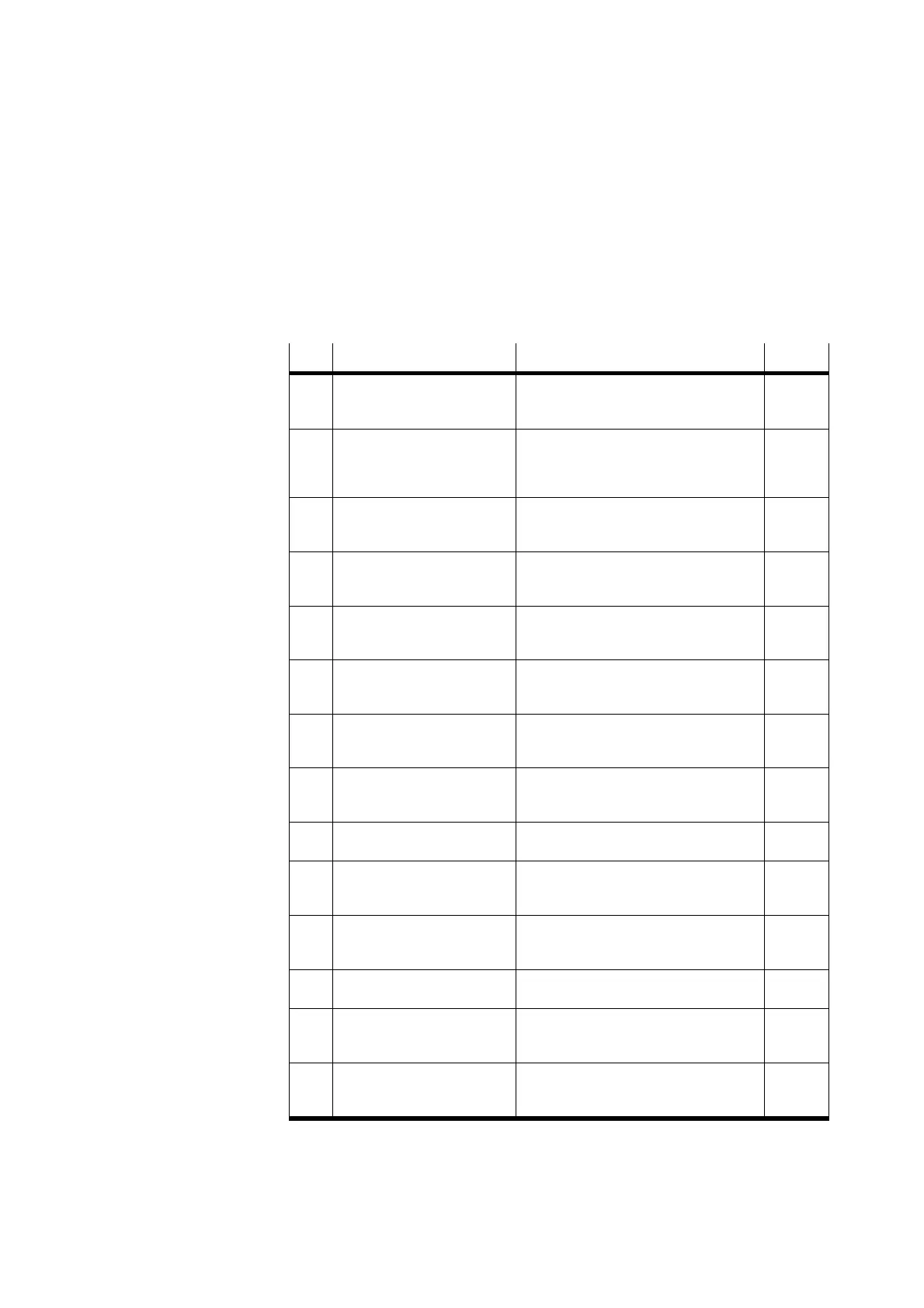

Error Error Location/Page No.: Error Description Installed

1 Isolate wire at clamp 12 directly

on the PLC

PLC-board/page 8 circuit no. 1

Start-button have no function à not

possible to start the process after homing

2 Close the one way flow control

valve of the lifting cylinder move

back

Pneumatic

The piston rod of the lifting cylinder cannot

reach the back position after move down a

workpiece à program stop

3 Isolate wire at clamp 4M directly

on the PLC

PLC-board/page 6

all lights are not working

4 Deadjust the sensor 2B1 for

lifting cylinder in up position

Pneumatic

The station is not possible to reach the

homing position à no start of the sequence

5 Isolate wire at clamp 15 directly

on the PLC

PLC-board/page 8

Station is always in Stop-mode à can not be

started

6 Isolate wire at clamp XMA2/0V

from Q0 on the station

Station/page 5

The handling cannot move to the previous

station à handling is not possible to pick up

a workpiece in the previous station

7 Isolate +-connection (red) of

external power supply

PLC-board/page 4 circuit no. 1

No power on the whole system

8 Remove the fuse F1 on the PLC-

board

PLC-board/page 4 circuit no. 1

No power supply on the PLC

9 Delete program from the PLC

(simulation of battery failure)

No program execution

10 Isolate wire at clamp XMA2/3

from Q2 on the station

Station/page 5

The lifting cylinder cannot move down à

program stops at the position previous

station

11 Isolate wire at clamp XMA2/20

from I7 on the station

Station/page 4

The light barrier is always off à even there is

a connected station, the Handling never

receive the signal Station available

12 Deadjust the workpiece

mounting

The workpiece can not be taken from the

mounting à careful possible crash!!!

13 Deadjust the sensor 1B2 for

handling is at following station

Pneumatic

The workpiece cannot be inserted to the

following station correctly

14 Isolate wire at clamp 38 directly

on the PLC

PLC-board/page 10 circuit no. 7

The communication output to the following

station is not working à following station

never start the process

Loading...

Loading...