Commissioning

24 © Festo Didactic GmbH & Co. • MPS

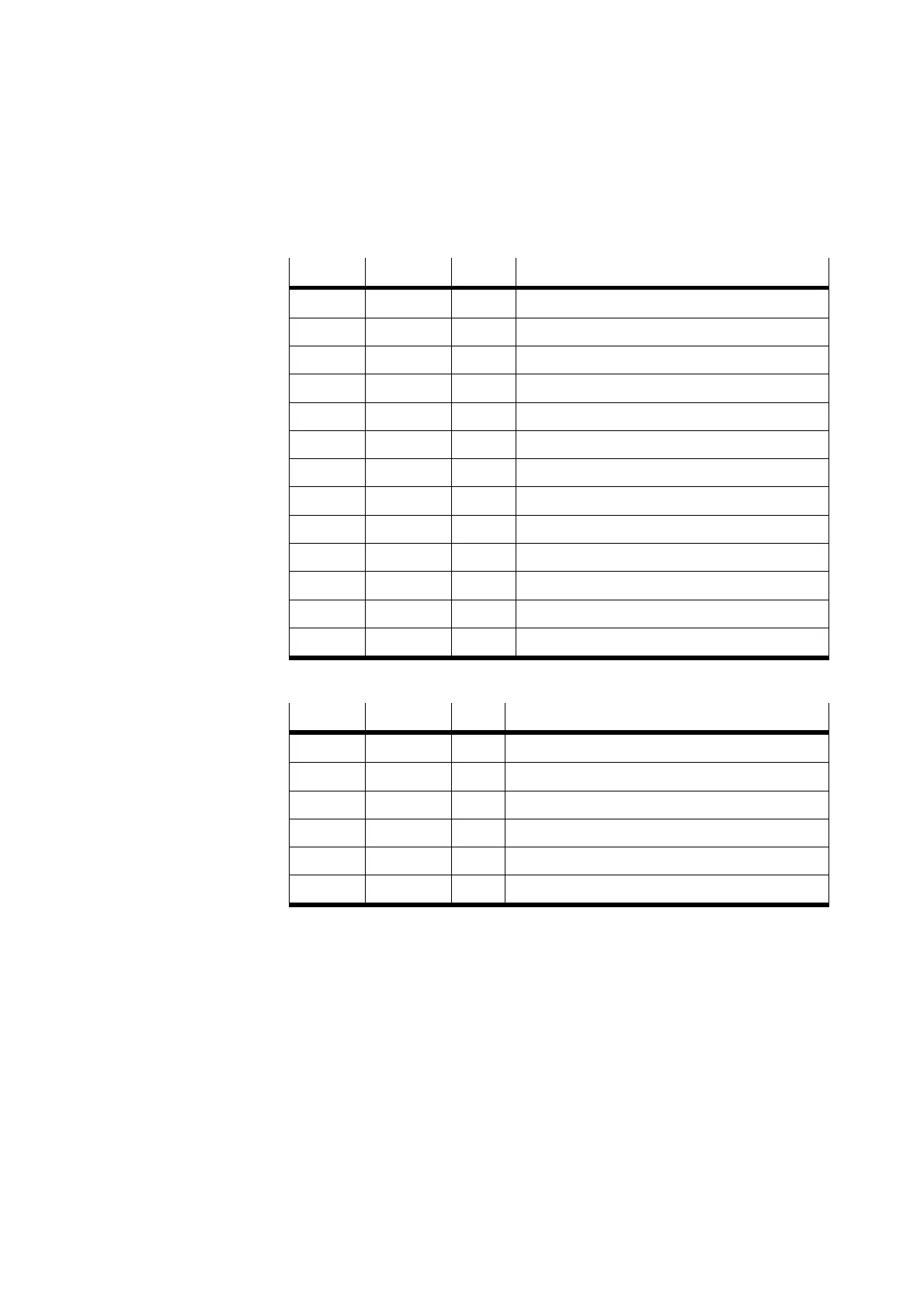

I/O Station

Adress Symbol Ident. Description

I0.0 Part_av Part_AV

Workpiece is available

I0.1 Han_prev 1B1 Handling at previous station

I0.2 Han_foll 1B2 Handling at following station

I0.3 Han_sort 1B3 Handling at sorting position

I0.4 Lift_dow 2B1 Lifting cylinder with gripper is down

I0.5 Lift _up 2B2 Lifting cylinder with gripper is up

I0.6 Sen_mat 3B1 Material detection signal = 0 = black

I0.7 Follow IP_FL Light barrier to the following station

Q0.0 Handprev 1Y1 Solenoid of handling cyl.to previous station

Q0.1 Handfoll 1Y2 Solenoid of handling cyl.to following station

Q0.2 Lifting 2Y1 Solenoid of the lifting cylinder with gripper

Q0.3 Gripper 3Y1 Solenoid of the gripper = 1 = open

Q0.7 Previous IP_N_FO

Light barrier to the previous station

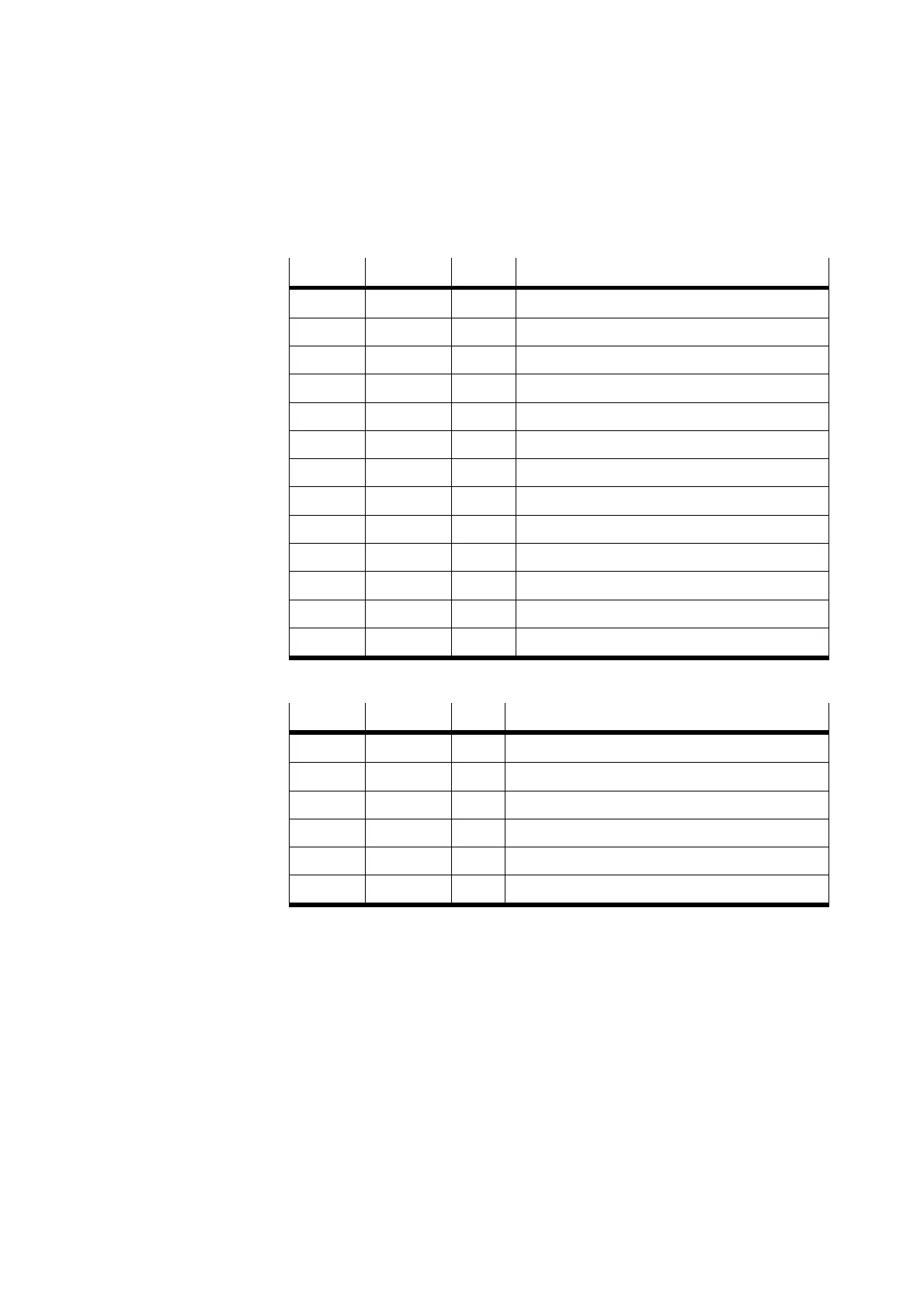

Adress Symbol Ident. Description

I1.4 CI1_Prev Input comm. from Q1.6 Previous Station

I1.6 CI1_Foll Input comm. from Q1.4 Following Station

I1.7 CI2_Foll Input comm. from Q1.5 Following Station

Q1.4 CQ1_Prev Output comm. to I1.6 Previous Station

Q1.5 CQ2_Prev Output comm. to I1.7 Previous Station

Q1.6 CQ1_Foll Output comm. to I1.4 Following Station

Q0.2 à Deadjust the workpiece mounting so that the gripper is not able to pick up

the workpiece centred and close the one-way-flow control valve of the lifting

cylinder to move up. Disconnect the 4 mm cluster plug cables of the

communication to the previous and the following station.

Disconnect the power- and air supply and disconnect the station from the other

following station. Disconnect the cable connections between the station and the

PLC-board and remove the whole board from the trolley. Remove also the control

panel from the trolley.

Loading...

Loading...