31

COUPLING MAINTENANCE:

Coupling alignment should be checked seasonally or every 500 hours.

1. Remove coupling guard.

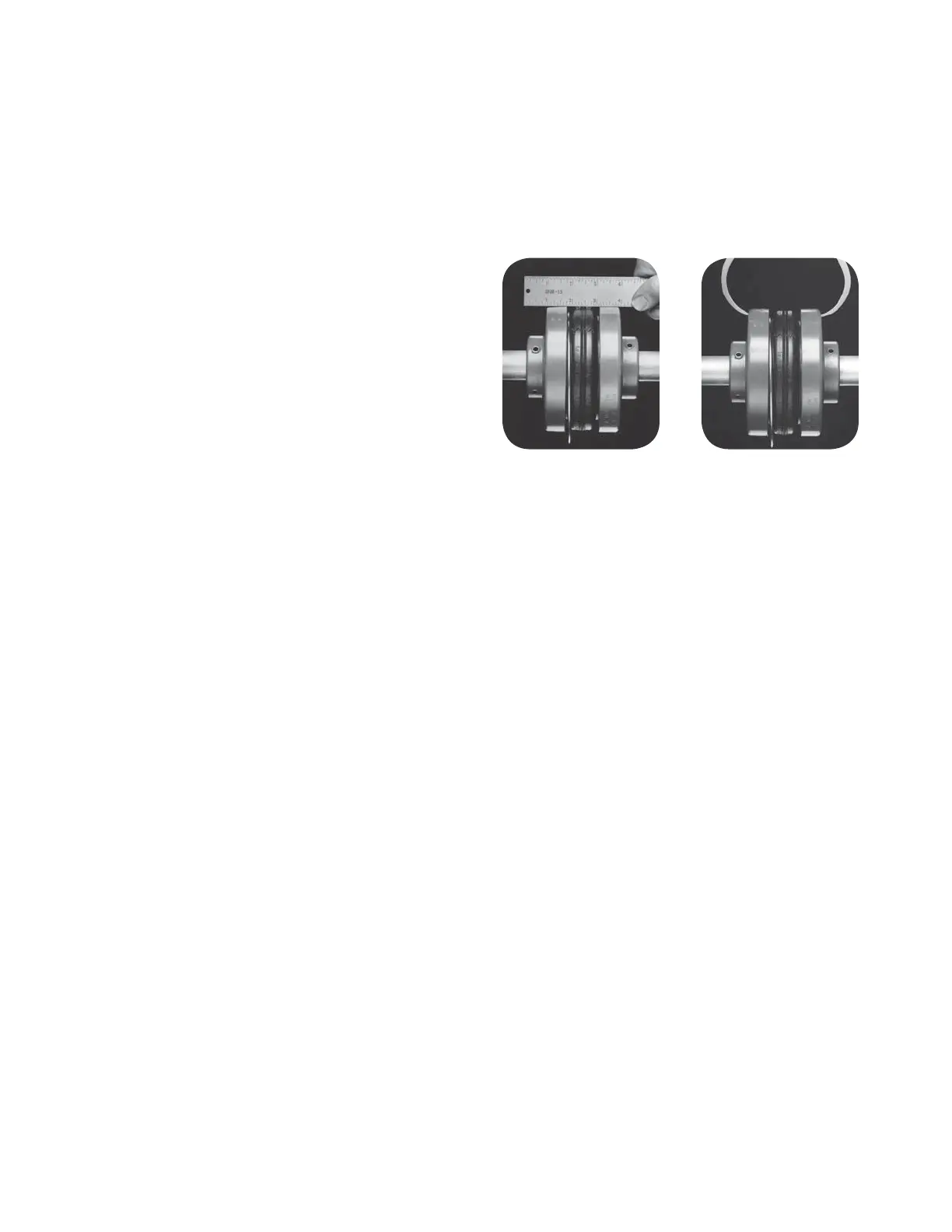

2. Check parallel alignment by placing a straight-edge across the two coupling flanges and

measuring the maximum offset at various points around the periphery of the coupling

without rotating the coupling. If the maximum offset exceeds 0.025 in., re-align the shafts.

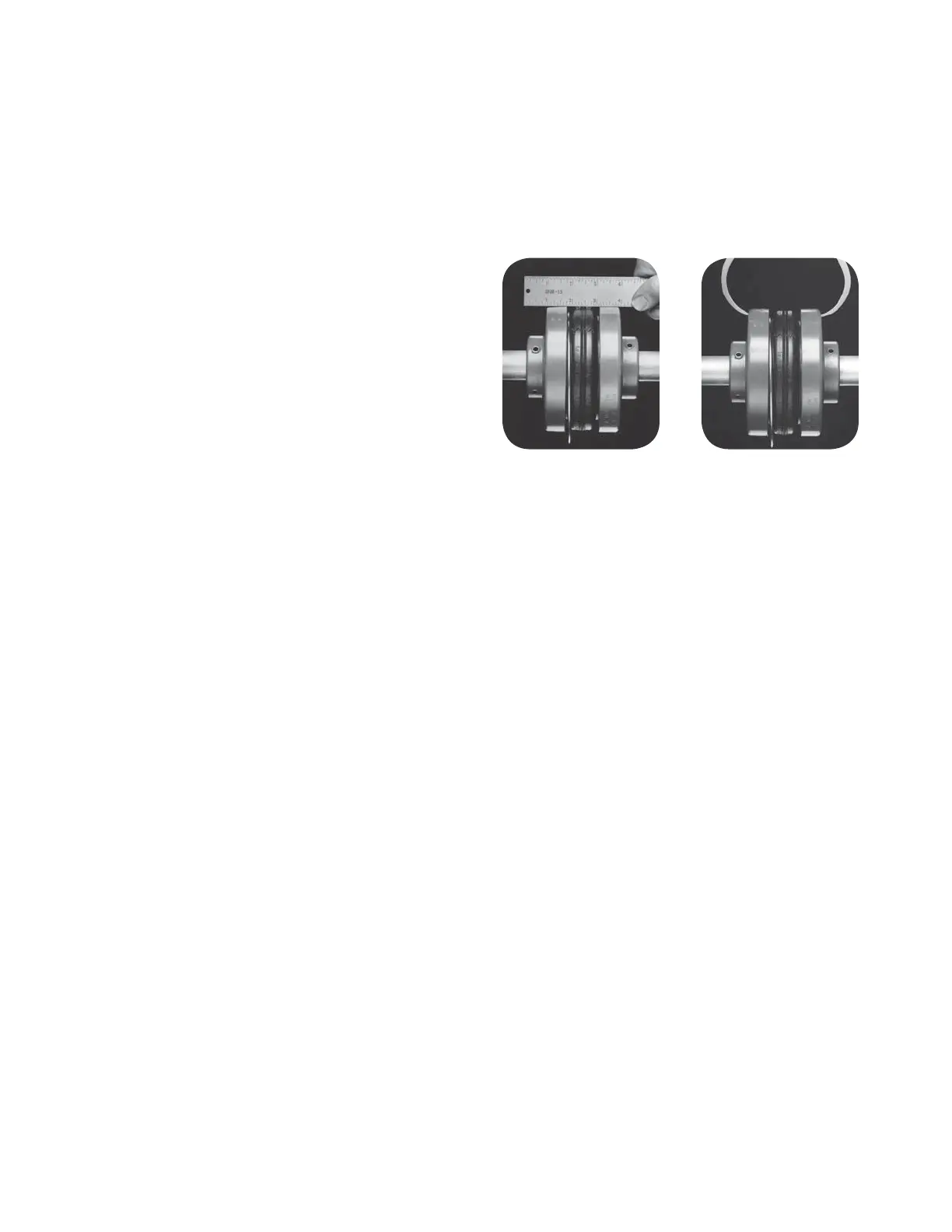

3. Check angular alignment with a

micrometer or caliper. Measure from

the outside of one flange to the outside

of the other at intervals around the

periphery of the coupling. Determine

the maximum and minimum dimensions

without rotating the coupling. The

difference between the maximum and

minimum must not exceed 0.109 in.

If a correction is necessary, be sure to

recheck the parallel alignment.

4. Reinstall coupling guard.

Note: PTO shaft height is adjusted by loosening the bolts that attach the engine mounting feet

to the engine block, adjusting the engine position and re-tightening the bolts. The PTO

shaft lateral position is adjusted by loosening the 6 bolts that attach the engine mount

adapter plate to the machine frame, adjusting the engine position and re-tightening the

bolts. It is not recommended that the four engine isolator mounts be loosened to perform

coupling alignment. The compliance of the rubber mounts makes this difficult.

Parallel Angular

Loading...

Loading...