Assembly

5.1 Preparatory work

26 Edition 09/2022 M3401-02en

5.1.1 Milling the finished bore5.1 Preparatory work

The diameter of the finished bore depends on the shaft used.

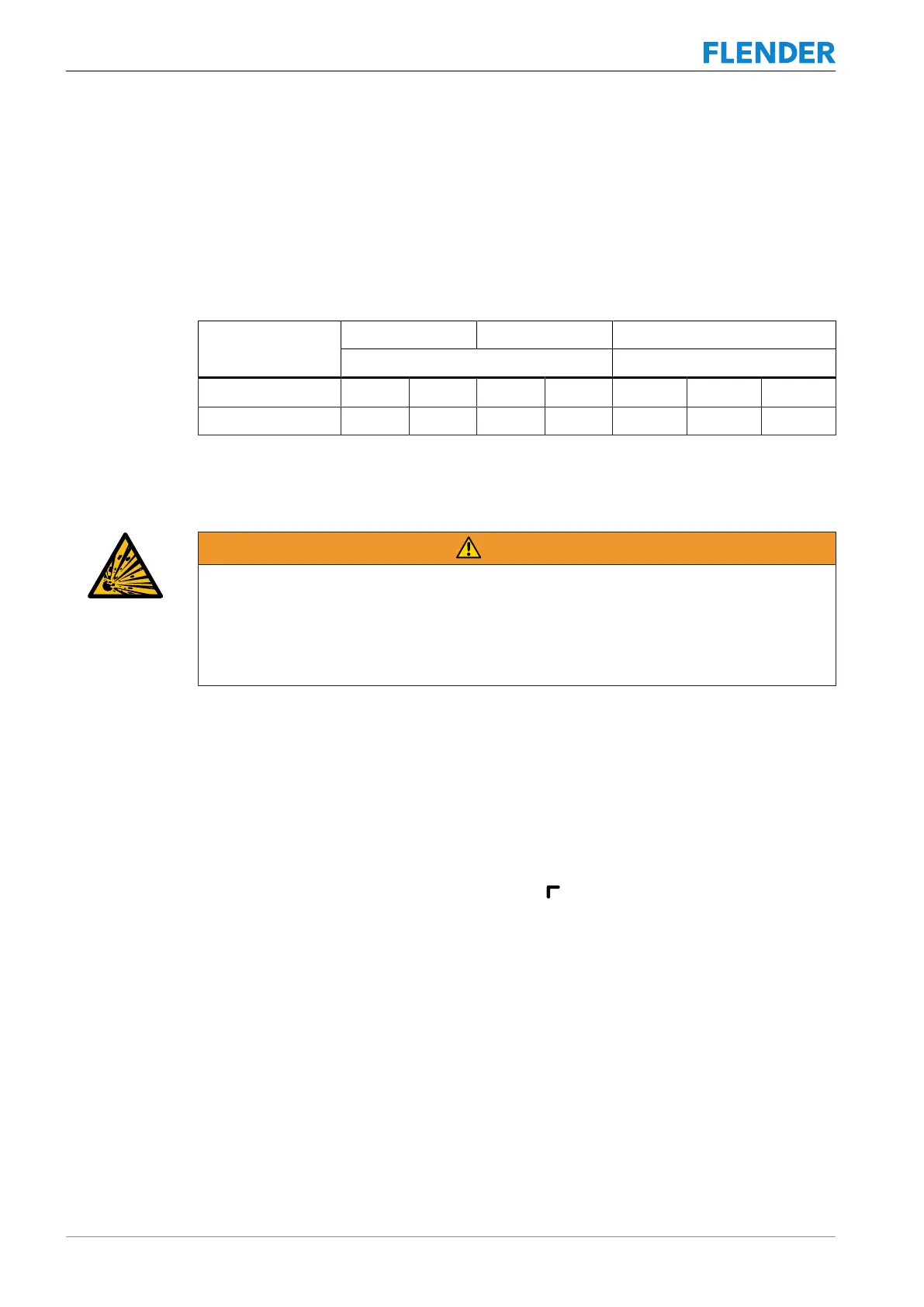

Recommended assigned fits

In the following table you can find the recommended assigned fits for bores with a parallel

key connection. The assigned fit m6 / H7 is especially suitable for a host of applications.

Description Push fit Press fit Interference fit

Not suitable for reversing operation Suitable for reversing operation

Shaft tolerance j6 h6 h6 k6 m6 n6 h6

Bore tolerance H7 J7 K7 H7 H7 H7 M7

Table5-1: Recommended assigned fits for bores with parallel key connection

Bore diameter

WARNING

Danger due to bursting of the coupling

If you exceed the maximum diameter of the finished bore, then this can cause the coupling

to burst in operation. There is a risk of fatal injury from flying fragments. If a coupling bursts

in an area at risk of explosion, then this can result in an explosion.

• Adhere to the maximum diameters specified.

The maximum diameters are listed in Section Speeds, geometry data and weights

(Page55)

Procedure

1. Remove the cam ring (50).

2. Remove the preservation and clean the coupling part 1/2 (1 or 2) to be machined.

3. Clamp the coupling to the areas marked with in the diagram below.

4. Machine the finished bore in accordance with the diagram below.

Loading...

Loading...