Technical data

Speeds, geometry data and weights

M3401-02en Edition 09/2022 59

Size Speed

n

max

rpm

D1 D2 DA

mm

ND1

mm

ND2

mm

NL1

mm

NL2

mm

D3

mm

DE

4)

mm

S

mm

S2

TAPER-

clamp-

ing

bush

No.

Weigh

t

5)

m

kg

max

2)

mm

min.

mm

max.

1

)

mm

mm

perm

dev.

mm

90 4,000 120 80 90 205 170 170 100 90 95 220 45 85 ± 3.0 3535

3)

20.7

TableA-3: Speed, geometry data and weights for BNT type

1)

Maximum bore for parallel keyway in accordance with DIN6885/1.

2)

Some bores have a flat groove.

3)

TAPER- clamping bush only possible in coupling part 4 (4).

4)

Required installation space.

5)

Weight applies to one coupling with maximum bore in coupling part 1/2 (1), without TAPER clamping bush.

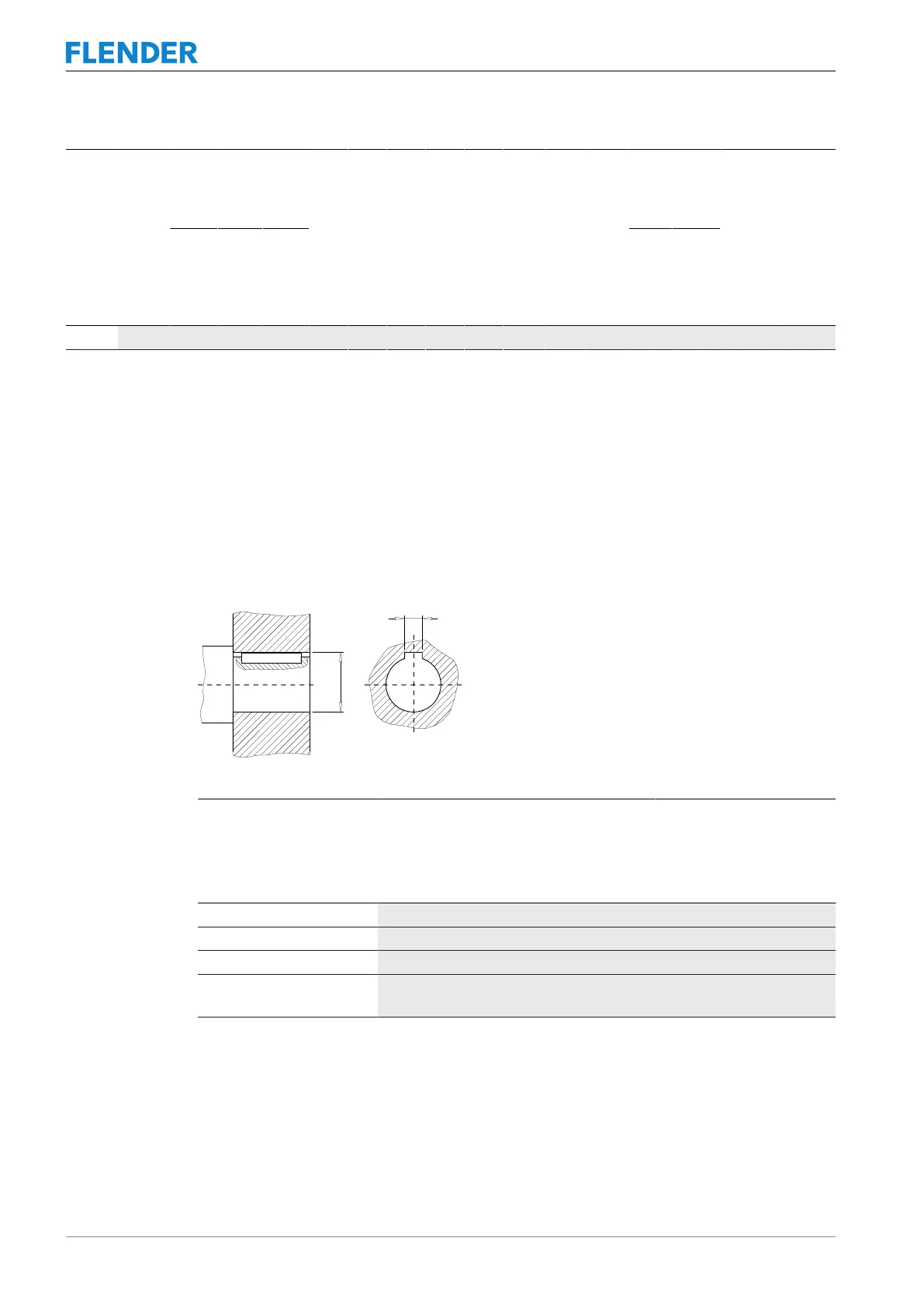

A.1.4 Flat groove in TAPER clamping bushes (101), (102) Speeds, geometry data and weights

FigureA-4:Flat groove in TAPER clamping bushes

TAPER-

Clamping bush

No.

Bore

D

mm

Width

B

JS9

mm

Hub groove depth

D + T2

mm

1008 24 8 D + 2

1008 25 8 D + 1.3

1108 28 8 D + 2

1610

1615

42 12 D + 2.2

TableA-4: Flat groove in TAPER clamping bushes

A.2 Shaft misalignment values during operation Shaft misalignment values during operation

The maximum permissible radial and angular misalignment depends on the operating speed.

Loading...

Loading...