Operation

7.2 Faults - causes and rectification

40 Edition 09/2022 M3401-02en

• Flange surfaces of screwed connections not cleaned.

• Alignment and/or shaft misalignment values not set in accordance with the instructions.

• Coupled machines were not correctly connected to the foundation so that a shifting of

the machines leads to an impermissible displacement of the coupling parts.

• Coupled machines not earthed adequately.

• Coupling guard used is not suitable.

7.2.2.2.3 Maintenance-related causes7.2 Faults - causes and rectification

• Stipulated maintenance intervals not adhered to.

• Spare parts that were used were not original spare parts from Flender.

• Flender spare parts that were used were old or damaged.

• Leak in the area of the coupling not detected so that chemically aggressive substances

damage the coupling.

• Indications of faults, such as noise or vibration, were not heeded.

• Stipulated tightening torques not adhered to.

• Alignment and/or shaft misalignment values not set in accordance with the instructions.

7.2.2.2.4 Specific installation-related and maintenance-related causes7.2 Faults - causes and rectification

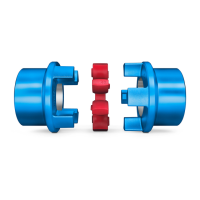

• Cam ring (50) not fitted.

• Fitted cam ring (50) excessively heated up when applying heat to the coupling parts.

7.2.3 Correcting faults7.2 Faults - causes and rectification

7.2.3.1 Replacing wearing parts7.2 Faults - causes and rectification

Cam rings (50) are subject to wear and this wear can result in torsional backlash.

Procedure

1. Check the wear on the cam ring (50) (see section Maximum permissible torsional back-

lash (Page44)).

2. Replace the cam ring (50) where appropriate (see section Replacing wearing parts

(Page44)).

7.2.3.2 Correcting the changed alignment7.2 Faults - causes and rectification

A changed alignment of the coupling during operation often occurs when the coupled ma-

chines shift towards one another. A cause of this can be loose foundation bolts.

Procedure

1. Correct the cause for the change in alignment.

2. Check the wearing parts for wear and replace them as required.

Loading...

Loading...