Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~68~

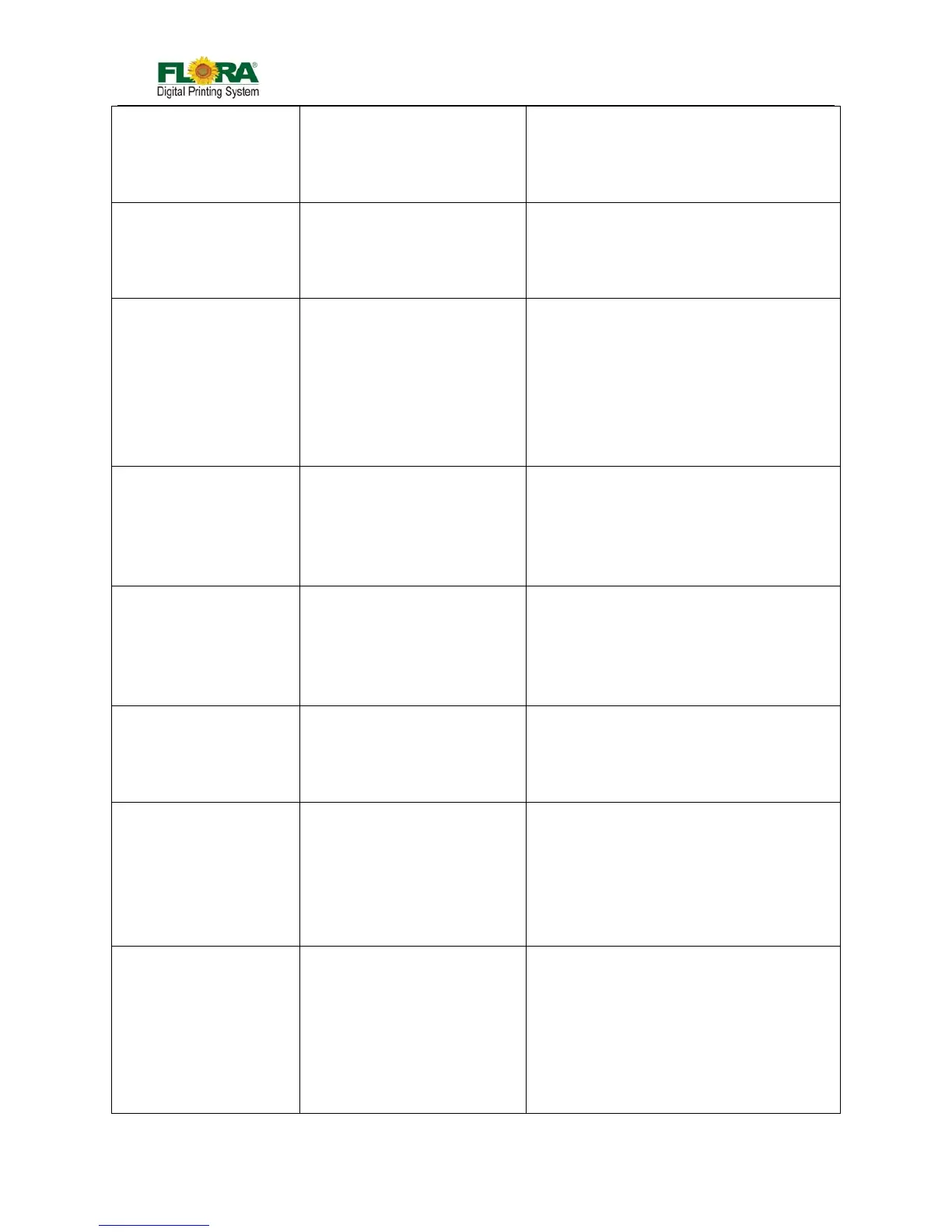

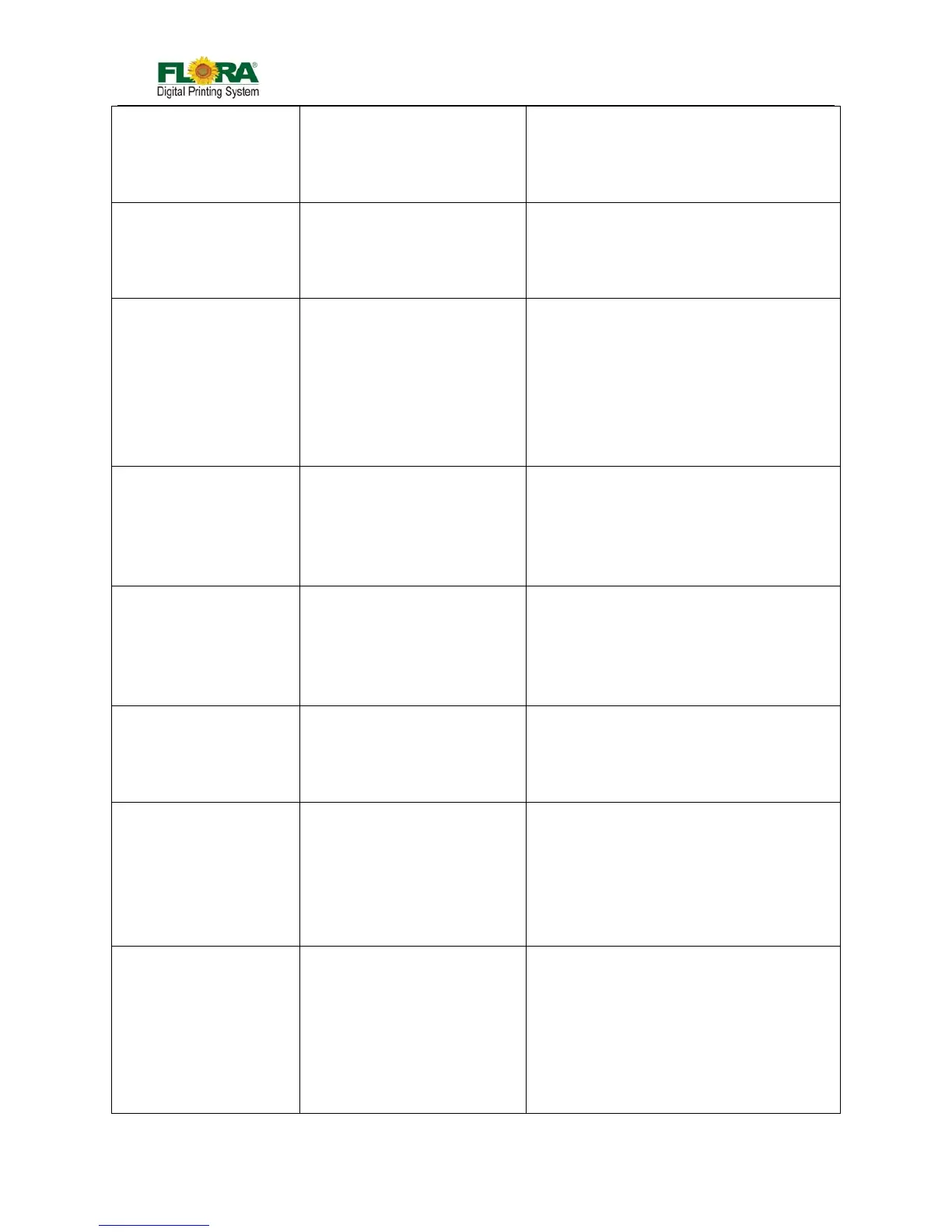

l Ink Pumps are not

working

o Presence of ink in the Ink

Protect Tank

o Defective / Out of Position Ink

Protect Level Sensor

Remove or purge any presence of ink in the Ink

Protect Tank

Replace/Fix Ink Protect Level Sensor by

opening the Ink Protect Tank

No Print at all

No presence of Printhead

Voltage from RTZ

software

o The Optical Cable must have

been interchanged during

installation

Interchanged again the Rx/Tx connection of the

Optical Cable either from the PCI card or in the

Printhead Control Board

Carriage gets in contact

with media during

printing

o Gap between carriage and media

(printing platform) is too close.

o Media suction is not working

o Wrinkled / curled media

Adjust the Printer Carriage between 2.0 –

2.5mm.

Check the 24V supply of suction fans, replace

defective suction fan if necessary

Replace the media to avoid wrinkled media to

be in contact with the print head during

printing

Carriage is not moving,

left to right stroke

o Defective AC Servo Motor

o Corrupted/Defective Servo

Driver

o Worn-out Timing Belt

o Defective Motion Control Board

Replace defective Servo Motor

Re-program the Servo Driver, replace if

defective

Replace worn-out Timing Belt

Replace Motion Control Board

Media is not moving,

backward and forward

stroke

o Defective DC Servo Motor

o Defective Movement Control

Board

o Worn-out Timing Belt

o Defective Motion Control Board

Replace defective DC Servo Motor

Replace worn-out Timing Belt

Replace Movement Control Board\

Replace Motion Control Board

PC has no communication

from the printer

Printer’s functionality

cannot be accessed

o Corrupted Printer Driver

o Defective PCI Card

o Defective 15pins I/O cable

Re-install the Printer Driver Software

Replace defective PCI Card

Replace defective 15pins I/O Cable

Ink is not drying

o Heat is not enough to dry the

ink

o Heater is not working

o Heater controller is not working

o Density or the ink limits of the

image setup is too high

Increase the heater’s temperature from the

printing platform as well as the front heater

Replace defective heater

Replace heater controller

Lower the ink limits of the image profile

Decrease the Ink limits of the image

Horizontal banding

o Clogged Print head

o Step alignment is not good

o Print head alignment is not good

Perform solvent flushing and Ink Priming

(make a longer flushing if needed) then check

the status of the Print head in Test Print

Adjust the motor steps (see Print head

Alignment Procedure)

Aligned the Print head very well (see Print

head Alignment Procedure)

Loading...

Loading...