Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~67~

Appendix A Troubleshooting Guide

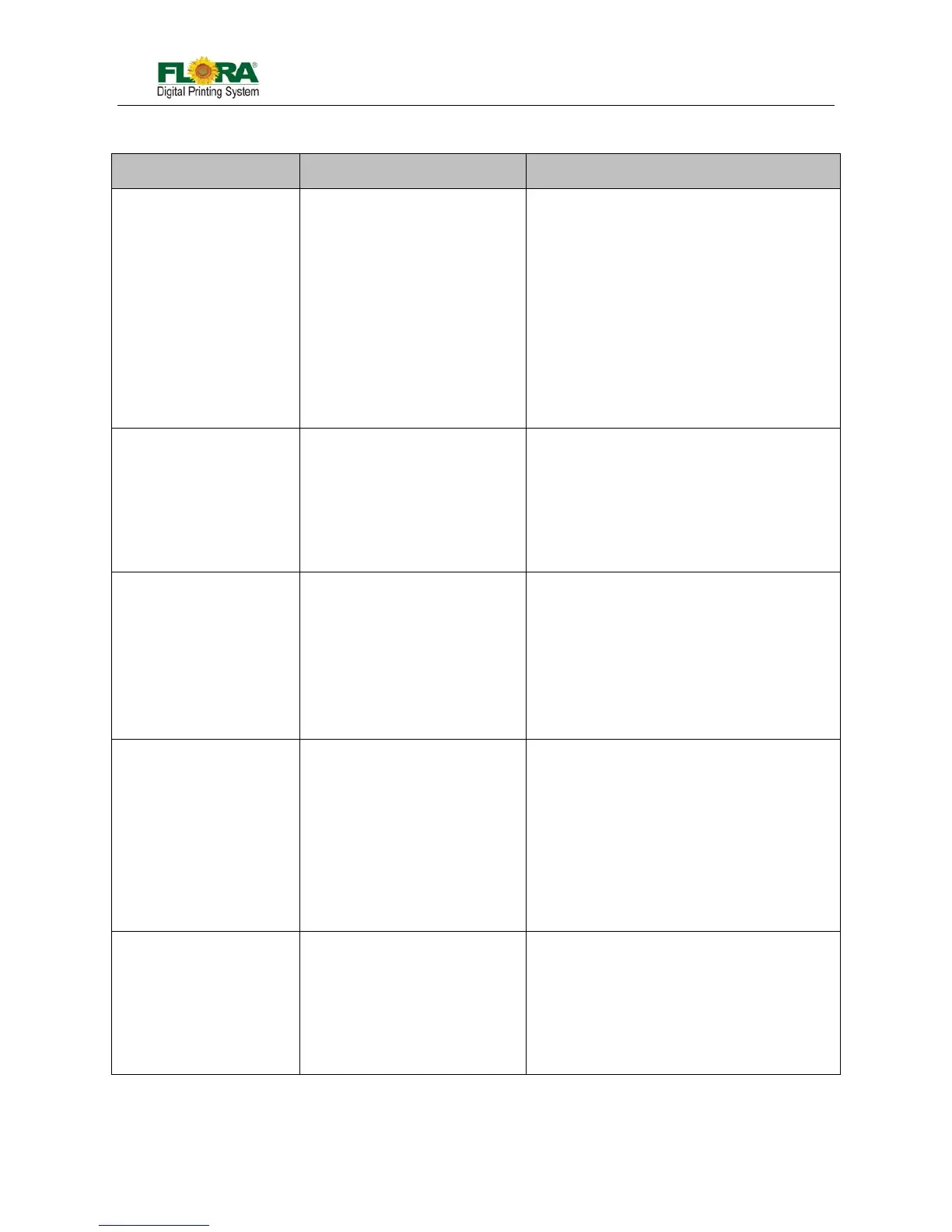

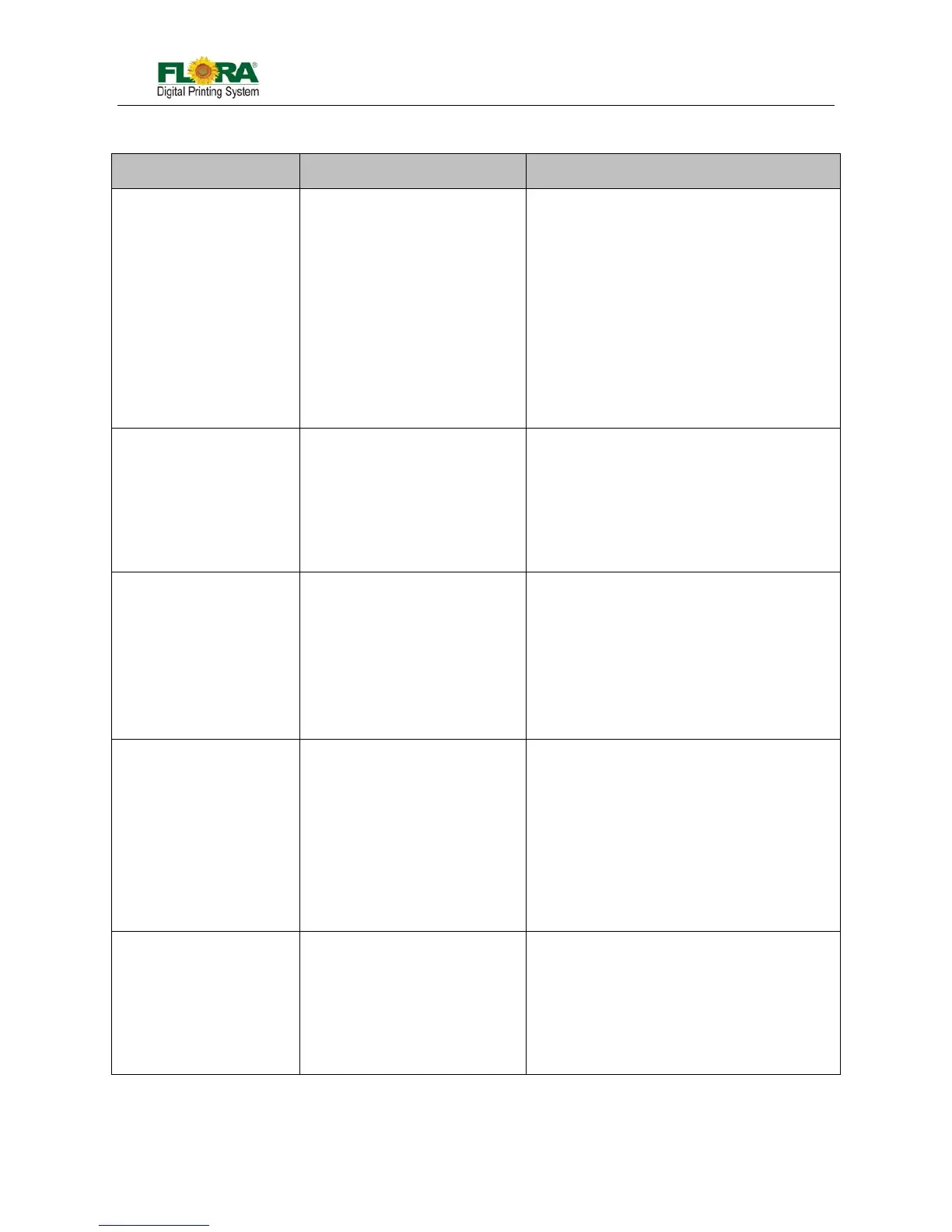

Problems Probable Causes Solution

One particular color is not

printing

o No ink flowing to the tube line

of the Print head Carriage

o Empty ink supply in the Ink

barrel

o Clogged Ink line tubing and ink

filter

o Defective Ink Pump

o Defective Print head Control

Board

o Defective Motion Control Board

• Fill-up empty ink barrel

• Replace clogged ink line tubing and ink filter

• Replace defective Ink Pump

• Replace defective Print head Control Board

• Replace defective Motion Control Board

Some Print head Nozzles

are not firing

Print head firing is not

straight

o Clogged Print head

o Print head problems

o Defective Print head Cable

o Defective Print head Control

Board

• Perform solvent flushing and Ink Priming

(make a longer flushing if needed)

• Replace defective Print head

• Replace defective Print head Cable

• Replace defective Print head Control Board

• Adjust the Print head Voltage

Ink Starvation

o Insufficient Negative Pressure

value

o Print head nozzles are not

working well

o Insufficient ink flowing from

the Disc Filter to the Print head

because of clogged disk filter

Increase the Negative Pressure value from

-1.8KPa to -2.1KPa

Perform Test Print to check if all the Print head

nozzles are working well, flush and ink prime

as needed

Replace Filter

Cannot achieve correct

negative pressure

Negative pressure keeps

on changing from time to

time

o Presence of ink in the Ink

Protect Tank

o Defective Negative Pressure

Regulator

o Defective Pressure Gauge

o Defective Air Pump

o Possible leak in the vacuum line

system (negative pressure line)

Remove or purge any presence of ink in the Ink

Protect Tank

Replace defective Negative Pressure Regulator

Replace Pressure Gauge

Replace Air Pump

Fix any air leak from the vacuum line system.

Replace Air Fittings if necessary

Air Pump is not working

Ink Pumps are not

working

o Presence of ink in the Ink

Protect Tank

o Ink Tank Sensor might not be

working that is why ink is

overflowing to the Ink Protect

Tank.

Fix/replace the Ink Tank Sensor

Remove the ink from the Ink Protect Tank

using the Syringe from the Ink Outlet Tube

vent

Loading...

Loading...